The design, development, and optimisation of mechanical systems and components are all included in the crucial field of machine design. It entails using scientific understanding, engineering principles, and pragmatic concerns to create devices that serve certain functions.

In a variety of sectors, including manufacturing, automotive, aerospace, and more, machine design is essential, from basic mechanics to intricate industrial gear. Gaining knowledge of the foundations of machine design and the many methods used in this subject will help you better understand the complex process of turning concepts into useful and effective mechanical systems.

In this reading, we’ll explore what machine design is, its diagram, types & their procedure.

Let begin!

What is Machine Design?

Machine design is a subfield of the mechanical engineering field; it is devoted to the design and development of mechanical systems and machines. It entails using design approaches, scientific knowledge, and engineering design concepts to produce machines that fulfil predetermined specifications and carry out intended tasks.

This includes choosing the right materials, figuring out the best sizes and shapes, developing mechanical parts, making sure the structure is sound, and taking efficiency, safety, and dependability into account.

Kinematics, dynamics, materials science, mechanical concepts, and manufacturing processes must all be thoroughly understood. In numerous industries, including manufacturing, transportation, and agriculture, the design and development of dependable and efficient machinery is critical to increased production and progress.

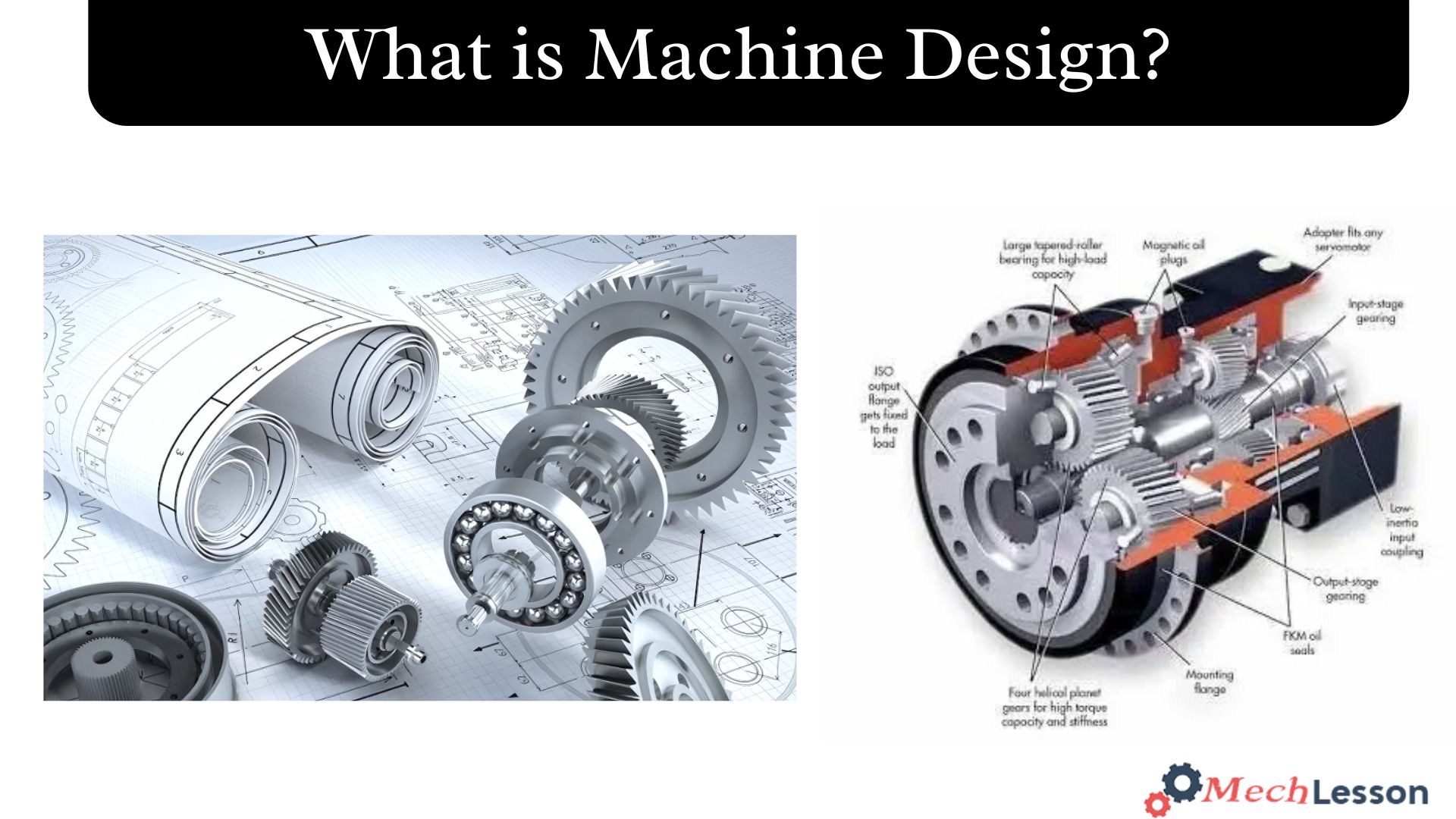

Diagram

Types Of Machine Design

Here are some common types of machine design:

Mechanical Machines: These basic mechanisms, including gears, levers, cams, and linkages, are found in these devices. To carry out operations like lifting, turning, or linear motion, they are made to transform and transfer mechanical energy.

Power Machinery: The purpose of power machines is to produce, transfer, and regulate mechanical power. Engines, turbines, compressors, and pumps are a few examples. They are used in many different sectors for things like pressurising fluids, producing energy, and supplying propulsion.

Manufacturing Machinery: This production machinery, including CNC (Computer Numerical Control) devices, lathes, milling machines, and 3D printers, is utilised in production operations. To manufacture things, they are made to cut, shape, form, or add material.

Transportation Machinery: Machinery used by transportation systems, such as cars, aeroplanes, ships, and railroads, falls under this category. These vehicles are built for stability, effective propulsion, and managing people or goods.

Agricultural Equipment: Farming and agriculture operations are facilitated by agricultural equipment. Tractors, harvesters, seeders, and irrigation systems are a few examples. They are designed to boost agricultural operations’ efficiency and production.

Construction Equipment: Equipment used in construction is made to perform activities associated with infrastructure development and building design. These devices include concrete mixers, cranes, bulldozers, and excavators. They are made for material handling, earthmoving, and heavy-duty tasks.

Automation and robotics: Automation systems and robotic machines are made to carry out activities on their own or with little assistance from humans. They are employed to increase productivity, accuracy, and safety in a variety of sectors, including manufacturing, healthcare, and logistics.

Special-Purpose Machinery: This group comprises devices made for certain sectors or uses. Machines used in textile production, food processing, medicine, and packaging are a few examples. These devices are specifically designed to satisfy the particular needs of their respective sectors.

Several Procedure of Machine Design

Here are some key procedures typically followed in machine design:

Problem Identification: Determining the issue or necessity of a machine is the initial stage in machine design. This entails being aware of the machine’s requirements, function, and purpose in addition to any limits or restrictions.

Concept Generation: After identifying the issue, designers come up with a number of conceptual ideas and methods to deal with it. This phase comprises thinking, researching, and exploring numerous design options.

Preliminary Design: At this phase, designers create a preliminary design based on the most promising idea. They establish the machine’s general specifications, dimensions, and overall layout. Materials, power needs, and operating conditions are among the factors that are taken into account.

Detailed Design: During this stage, the preliminary design is improved upon and comprehensive models, drawings, and specifications are created. In order to guarantee their correct integration and operation, designers concentrate on certain parts, mechanisms, and subsystems.

Material Selection: The machine’s performance, longevity, and cost-effectiveness all depend on the choice of materials. Factors like strength, rigidity, corrosion resistance, and availability are considered in choosing acceptable materials for different components.

Analysis and Simulation: Computer-aided analysis and simulation tools are employed to evaluate the performance and behaviour of the machine. Finite element analysis (FEA), computational fluid dynamics (CFD), and other simulation techniques are used to study aspects such as stress distribution, temperature behaviour, and fluid flow.

Prototype Development: Building a prototype allows designers to verify the design and evaluate its functionality. Before going into production, prototyping aids in locating any performance problems or design defects.

Testing and Evaluation: The prototype is subjected to various tests to validate its performance, reliability, and safety. To make sure the machine satisfies the necessary standards and specifications, testing may include functional, endurance, and load testing.

Manufacturing & Production: Once the design is finished and validated, the machine advances onto the production phase. Manufacturing processes, such as machining, welding, assembly, and quality control, are implemented to produce the final machine.

FAQs

What is meant by machine design?

Machine design is the process of creating new machines or improving existing ones by applying engineering principles, creativity, and practical considerations. Machine design is a complex process that requires the use of various methods to achieve the desired result.

What is a design machine?

Machine design in general is concerned with the development of power sources and functional mechanisms. However, designers invariably specialise; they may concentrate on such areas as the design of engines or turbines or the functional portions of automobiles, machine tools, or automation equipment.

What does a machine design engineer do?

It is the branch of engineering that combines mathematics, materials science, and engineering for the design, analysis, manufacturing or operation of machines and tools.

What is CAD in machine design?

CAD (computer-aided design) is the use of computer-based software to aid in design processes by creating simulations of real-world objects.