However, because flaws can be hard to find beneath the weld’s surface, assessing the quality of underwater welds can be challenging, particularly during wet welding. In 1932, the Russian metallurgist Konstantin Krenov created hyperbaric welding, which has since been used all over the world to repair pipelines, ships, and offshore oil platforms.

Well, in this reading, we’ll explore what underwater welding is, its application, diagram and types. We’ll also explore their payment, its danger & Safety Precautions.

Let’s begin!

Read about Fricton Stir Welding with this detailed guide!

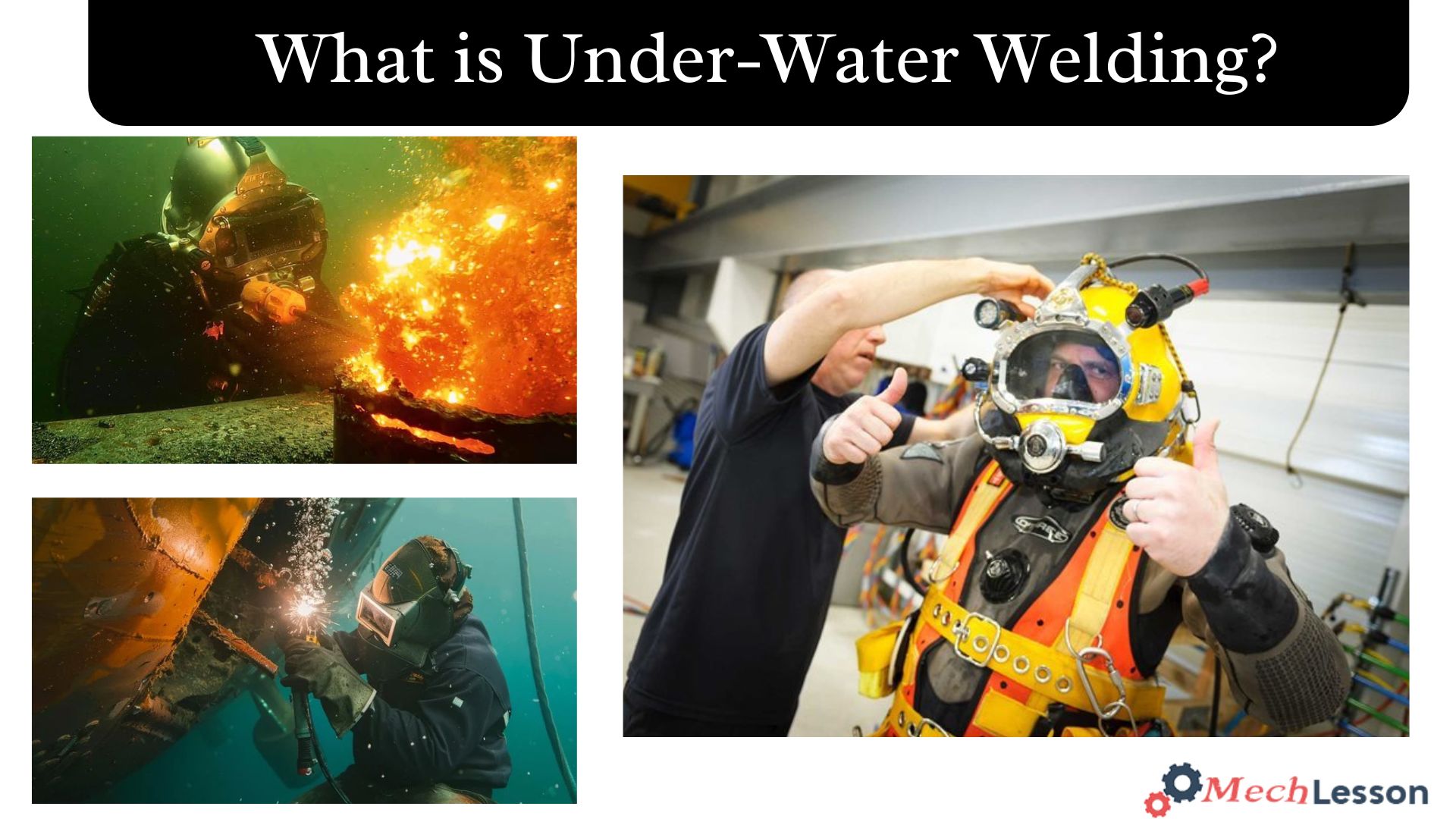

What is Underwater Welding?

Underwater welding, also referred to as hyperbaric welding, is the process of welding under high pressure. Steel is most often welded, and the process can be done in a dry, pressurised container (dry welding) or in the water itself (wet welding).

Dry welding is commonly referred to as “hyperbaric welding,” whereas wet settings are referred to as “underwater welding.” Due to the flexibility to execute pre and post weld heat treatments and the increased control over the welding circumstances, dry welds are often of higher quality than wet welds.

Application

- It’s used for offshore and marine applications.

- It’s often carried out in shallow waters or by moving structures to dry areas.

- It saves costs of removing structures from water and dry docking.

- It can be used for emergency repairs.

- Its used on ships, dams, oil rigs, pipelines, bridges, nuclear power stations, rivers, canals, etc.

Diagram

Types Of Underwater Welding

The two main categories of underwater welding techniques are:

Read about How Does Flux-Cored Arc Welding (FCAW) Works? with this detailed guide!

Wet Underwater Welding:

Wet welding involves carrying out the welding process directly in water and typically calls for a specially made welding rod. The welder is exposed to the weather because this kind of welding takes place in open water. Given the clear risk, some have suggested that wet welding should only be used as a last option.

One such concern is that the surrounding water may cause the welded joint to cool down quickly, which might result in joint flaws. But it also offers benefits, including low cost and speed, great tensile strength, access to weld areas, and no building required.

Dry Underwater Welding:

In contrast, dry welding uses a hyperbaric chamber that is set up to provide a dry atmosphere. Dry welding, in contrast to wet welding, is carried out in a dry environment made up of a variety of gases. Furthermore, welding is carried out in a chamber at the current pressure.

The gas mixture that fills this chamber is sealed around the object that is being welded. As a result, welding in this category is comparable to welding outside. However, the enclosed atmosphere is impacted by the welding fumes and gases.

Average pay and employment prospects for underwater welders

As you gain skill, you will probably hold more related positions because underwater welding is a specialised area that demands a great deal of mastery. Although Indeed does not have income statistics, particularly for underwater welders, fabricators and welders make an average of $57,387 a year, while welders make an average of $38,569 a year.

All welding types, including underwater welders, can be affected by these broad averages. The average annual salary for commercial divers is $53,100. Your income potential may differ for each of these career choices depending on the location and depth of the dive, as well as your expertise and certifications.

The United States Bureau of Labour Statistics projects that employment opportunities for welders, fabricators, brazers, and cutters will increase by 3% between 2019 and 2029. Many organisations have a strong need for trained welders since the work of an underwater welder and commercial diver can be dangerous. Future employment prospects may also arise from the building and expansion of infrastructure near coasts.

Read about Gas Welding with this detailed guide!

The Dangers/Hazards of Underwater Welding

Since welding is done in a dark environment, welders are always at danger. Most potential injuries are chronic and can even be fatal. Workers who weld underwater run the risk of electric shocks, explosions, exposure to dangerous chemicals, and even drowning.

Underwater welders are extremely vulnerable to shocks, explosions, and electrocution. Welders employ protective gear or waterproof tools for this purpose. This kind of welding involves the use of hazardous materials, such as lead, or the potential for waste.

Furthermore, decompression sickness would result from an excess of nitrogen in the blood. Extreme cold might produce hypothermia if there was insufficient equipment or tools. If there are unlucky equipment malfunctions underwater, drowning is also a risk. It may imprison the diver or welder since it is difficult to escape given the surroundings.

Safety Precautions

These are the following safety precaution methods for underwater welding:

- It uses an appropriate DC welding generator with straight polarity.

- Its always wear insulated gloves during welding.

- Attach the earth clamp close to the worksite to prevent diver from touching the electrode and earth.

- Its ensure a knife/disconnect switch on the stinger side of the current.

- Check polarity by immersing the electrode tip and earth clamp in saltwater.

- Clean a spot for the earth clamp in front of the diver.

- Its make a test weld to check “heat” at working depth.

- It keeps the hand closer than 4″ from the electrode tip.

Read about How Does Flux-Cored Arc Welding (FCAW) Works? with this detailed guide!

FAQs

Is underwater welding a good career?

Yes, underwater welding is a specialised and increasingly popular job, particularly in industries such as construction, oil and gas, and marine engineering.

Underwater welding combines commercial diving skills with welding expertise, which can make it a lucrative career.

What’s the highest-paid welding job?

The 5 Highest-Paying Welding Jobs

Rig Welder. Annual Salary: $52,000–$207,000…

Underwater Welder. Annual Salary: $38,000–$147,000…

Nuclear Welder. Annual Salary: $22,000–$143,500.

Industrial Pipeline Welder. Annual Salary: $23,500–$133,000.

Military Support Welders. Annual Salary: $37,000–$160,000.

What is the underwater welding?

Underwater welding, commonly referred to as hyperbaric welding, involves welding under intense pressure. There is wet water welding that takes place inside the water or dry welding that takes place in a dry, pressurised enclosure and steel is the most common metal used material used to weld.

What qualifications do you need for underwater welding?

Use the following steps to get an idea of what it takes to become an underwater welder:

Get your high school diploma or GED.

Earn your welding certification. …

Attend a commercial diving school. …

Complete your physical exams. …

Attend an underwater welding school.