A drilling machine, which is also known as a drill press, is a cutting process that uses drill bits of various sizes to cut a hole of circular section in solid materials like metal, plastic, wood, rocks, etc.

The drill bit, as the cutting tool rotates, is often multi-point. This drill, which rotates from hundreds to thousands of revolutions per minute, is pressed against the workpiece with force. The force applied causes the cutting edge to cut off chips from the workpiece.

Drilling is a common process in the manufacturing industry, which is why all mechanical engineers must know about it. In this reading, we’ll explore what a drilling machine is, its parts, diagram, types, specifications, and how it works. We’ll also explore the drilling machine tools, advantages and disadvantages.

Let’s get started!

Learn about drilling with this detailed guide!

What is Drilling Machine?

A drilling machine is a powerful tool used to create holes in a workpiece, often used in woodworking, metalworking, construction, and utility projects. It is equipped with a drill bit and either a drill or driver chuck and is used to make cylindrical holes of a specified depth and diameter on a workpiece.

The drill bit is held in the drill press by a chuck and fed into the work at variable speeds. The speed and feed should be set properly, and coolant is provided for the desired finished part.

Drilling operations are performed on wood and metal, making it one of the most important machine tools. The machine tool was first invented to make cylindrical holes in metals, but there are different machine tools in the workshop capable of creating holes.

The first handheld portable drilling machine was developed by Wilhelm and Carl Fein in 1895, and the first pistol-grip portable drill with a trigger switch was patented by Black & Decker in 1917.

Today, drilling machines are widely used in various operations, including plane drilling, step drilling, core drilling, boring, counterboring, reaming, countersinking, spot facing, tapping, and trepanning.

Drilling Machine Parts

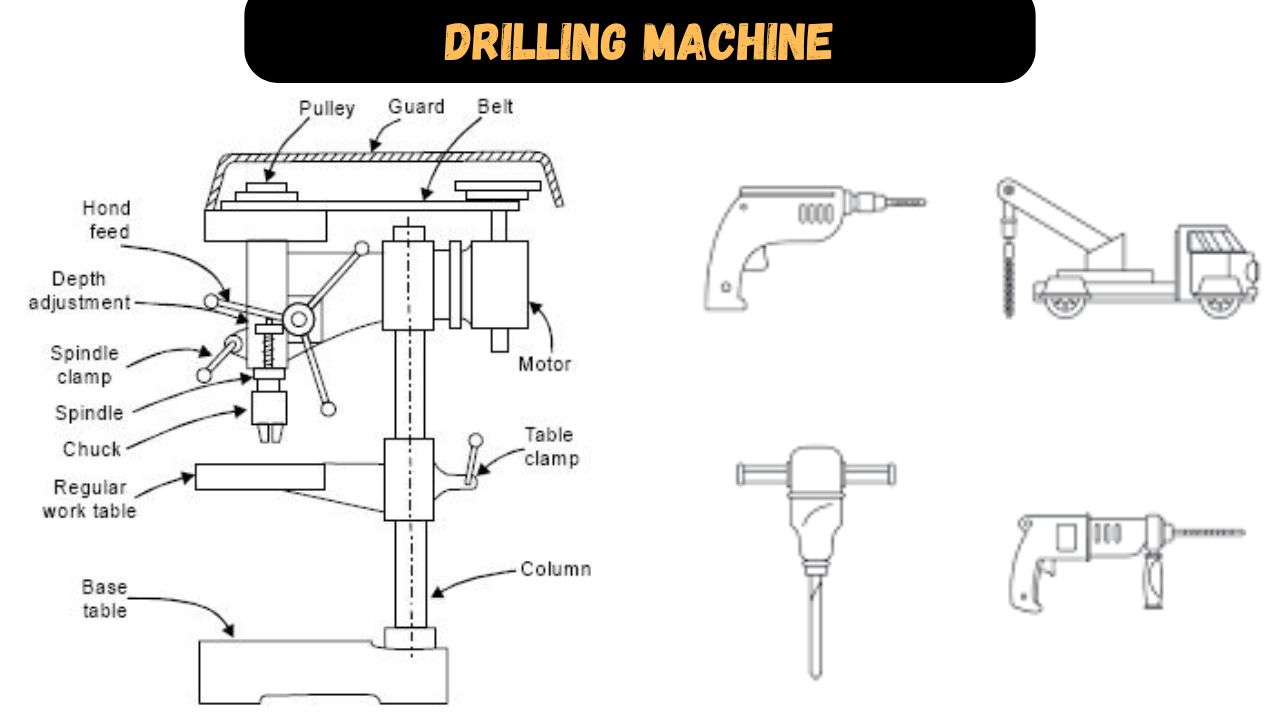

The major components of a drilling machine are the base, column, upper arm, worktable, drill head, feed mechanism, spindle, chuck, electric motor and pulley.

Base

These parts of a drilling machine carry the entire weight of the machine and transfer it to the ground. This base is generally made of cast iron or steel due to its strength. the top of the base contains some slots to support the big jobs and the radial column is situated at one side of it. Generally, the base is bolted to the ground, and in some cases, it is supported by two or four legs.

You should also learn about the best right-angle drilling machine with this detailed guide!

Column or Pillar

Just as mentioned, the column or pillar is situated on one side of the base. The radial column is mostly used due to the fact that it features a movable arm, having the possibility to move clockwise and counterclockwise.

The column is also made of cast iron or steel, as the strength operation is needed so as to carry the load of the arm as well as the drill head. A sliding head table is mounted on the column so that the table can have up-and-down motion as required.

Upper Arm

The drilling machine part carries the drill head and the housing containing the driving mechanism. This material is also made of the same material as the base, making it have a rigid structure. Some manufacturers of drilling machines provide a guideway so the drill head can slide over the upper arm.

Worktable

The worktable is mounted on the column; it is made of cast iron. A t-slot is provided at the top surface of the table and some tables contain a vise, depending on the operation to be performed. The worktable is designed to move up and down and also right and left according to the job and tool arrangement. The adjustment of the table can be done by hand as well as by some electrical mechanisms.

Drill Head

A drill head consists of various driving mechanisms. The drill head is mounted to one side of the drill arm and a drill chuck is mounted over it. this drill head is designed to slide up and down depending on the requirement of the job.

A V-belt is used to transfer the power from the motor to the pulley and from the pulley, the mechanical power is transferred to the drill head. Different speeds are generated by the cone pulley mechanism as well as a gear-train mechanism.

Feed Mechanism

This drilling machine component receives power from the electric motor to the V-belt and pulley. The up-and-down movement of the drill head is automatically fed by an electrical motor as well as manual feeding, which is done by hand. Rack and pinion can also be used to convert the rotational movement from an electrical motor or by hand to the straight-line movement.

Spindle

The spindle is a circular taper shaft that is used to hold the drill chuck. It is made of high-carbon chromium steel stainless steel or steel alloys. The rotary motion is transferred from the drill head to the drill jigs; a keyhole is provided on the spindle. This enables the drill chuck to be changed. The rack and pinion mechanism also helps the up and down movement of the spindle.

Learn about Lathe machine with this detailed guide!

Chuck

These parts of the drilling machine are mounted on the lower end of the spindle, which holds the drill jig. A keyhole is also provided on this component, allowing the drill jigs to be changed. Unlike a lathe, drill chucks are generally self-centering and a three-jaw chuck is used. They are made with special alloy steel.

Electric Motor

In a drilling machine, a single-phase ac motor is used; it can run at a rpm of 600 to 5000. More rpm is used for high-drilling machines. The electric motor supplies mechanical power from the pulley to the spindle and allows different speeds.

Pulley or Gears

These components are used to transmit power and also for generating different speeds. A bevel gear is used mostly in a drilling machine to transmit power at an angle of 90 degrees. Pulleys are made of cast iron.

Learn about Milling machine with this detailed guide!

Diagram of drilling Machine

Specifications of a Drilling Machine

The specifications of a drilling machine include power source, motor capacity, drill chuck size, spindle speed, drill depth capacity, feed rate, and drill bit compatibility.

Power Source

Most drilling machines predominantly rely on electricity as their source of energy, which ensures a reliable and consistent performance. Modern portable drilling machines are equipped with batteries, which ease usage in remote locations, adding to their convenience and flexibility.

Also, some advanced models incorporate hydraulic systems to enhance power and precision for specialized applications.

Learn about the best drill press with this detailed guide!

Motor Capacity

Different motor capacities are incorporated on drilling machines, which cater to a wide range of workloads and applications. The motor capacity varies from compact units suitable for light operations to robust machines designed for heavy operations.

The drilling machine motor capacity is typically measured in horsepower (HP) or Kilowatts (kW). With this, there is a clear indication of the machine’s power output.

Drill Chuck Size

The Chuck size of a drilling machine is used to determine the maximum diameter of the drill bit that the machine tool can accommodate. Drill chuck sizes are 1/2 inch, 3/4 inch, and 1 inch, allowing for various drilling requirements. This gives the machine the flexibility to handle different varieties of projects with varying hole diameters.

Spindle Speed

The spindle speed is measured in revolutions per minute (RPM), which indicates the rotational speed of the drill bit. Different spindle speeds are required for specific applications to achieve great results.

This is why drilling machines are designed to have adjustable speed settings, which allow the operators to customize the speed to meet the needs of different materials, operations, and sizes.

Drill Depth Capacity

The drill depth capacity is the maximum depth a machine drill bit can penetrate into a workpiece material. It is required to choose a drilling machine with an appropriate depth capacity, which is important for precise and efficient drilling operations.

With this machine tool specification, the drilling machine can meet the specific requirements of different drilling projects.

Feed Rate

Feed rate in a drilling machine is the speed at which the drill bit make into the material during the operations. Drilling machines with adjustable feed rates give the operator flexibility to control the drilling speed according to the requirements of the materialwhich can determine the outcome of the project.

Drill Bit Compatibility

Drilling machines are designed to be incorporated with different types and sizes of drill bits. Drill bit types are twist drills, spade drills, hole saws, and step drills. Chuck size and machine configurations are used to determine the compatibility of the drill bits with the drilling machine.

You should also learn about the best cordless drilling machine with this detailed guide!

Types of Drilling Machine

The various types of drilling machines are portable drilling machines, sensitive drilling machines, upright drilling machines, radial drilling machines, gang drilling machines, multiple spindle drilling machines, and deep hole drilling machines.

Portable Drilling Machine

This drilling machine is also known as a hand drilling machine; it is the most common and widely used by manufacturing companies. Unlike other standard tools, this machine tool is used for drilling holes in rocks, wood, metal, etc.

As the name suggests, the machine is small in size and can be carried to any work location. It works with a universal type of motor and it can drill from about 12mm to 18mm in diameter. Portable drilling machines are quite efficient and can be operated at higher speeds

Sensitive Drilling Machine

The sensitive drilling machines are also called bench drilling machines; they are used for making small holes at a very high speed. It is mounted on a bench with bolts and nuts and can be installed by hand. It also comes with a base, table, spindle, drill head, and driving mechanism.

Upright Drilling Machine

The upright types of drilling machines are specially designed for handling small to medium-sized workpieces. However, it is a sensitive drilling machine; it is heavier than a normal drilling machine. The upright drilling machines come with a spindle feed and speed, making them suitable for different types of work.

Learn about Lists of Best Magnetic Drill Press with this detailed guide!

Radial Drilling Machine

These types of drilling machines are designed for making a hole in large and heavy workspaces. it supports a radial arm in the column, which allows the table to move up and down in order to drill workpieces of different heights. It is also used as a rock drilling component that construction companies can easily use.

The radial drilling machine driving mechanism has separate feeds and different speeds. The position of the machine is adjusted by sliding the drill head and the gateway of the arm.

Gang Drilling Machine

the gang drilling machine has a long common table and a base like the other machines. It also contains 4-6 drill heads placed side by side, the drill heads have separate driving motors for their working.

Gang drilling machines are used for operations like drilling, reaming, counterboring, and tapping. It is done by simply moving the machine back and forth. Different spindle tools are used for different operations.

Multiple Spindle Drilling Machines

When listing some of the important types of drilling, those that cause multiple spindles must be mentioned. It is designed to drill a number of holes in a workpiece or drill identical pieces, as it comes with several spindles. These spindles drill all fed at the same time and also alter the distance between the axles to manage the holes in the drill.

Deep Mole Drilling Machine

This is a special type of drilling machine, designed to drill deep holes in the connecting rods and spindles as well as in the barrels of the gun. They are perfect for creating deep holes, achieved with high cutting speed and less feed and coolant must be used during the process.

Learn about electrochemical grinding (ECG) with this detailed guide!

How Does Drilling Work?

In the working of a drill, the swarf is carried away from the tip of the drill bit by the fluting of the drill bit. The cutting tip produces more chips, which continue the movement of the chips outwards from the hole. Cutting fluid or coolant is sometimes applied to prolong the tool’s life by cooling and lubricating the tip and chip flow.

When using a gun drill, coolant may be introduced with the drill shank; it is used mostly while drilling aluminum. The cutting fluid helps to ensure smooth and accurate cutting and prevent the metal from grabbing the drill bit while drilling the hole.

When cutting soft metals like brass, that can cause grabbing of the drill bit and even cause chatter. 1-2 mm can be ground on the cutting edge to create an obtuse angle of 91 to 93 degrees. This prevents chatter and instead cuts the metal. The cutting tool edge pushes away the metal rather than grabbing the metal, creating high friction and hot swarf.

On heavy feeds and comparatively deep holes, oil-hole drills are used in the drill bit. It is designed with a lubricant pump to the drill head through a small hole in the bit and flowing out along the fluting. The arrangement of a conventional drill press can be used in oil-hole drilling. However, it is more common in automatic drilling machinery because the workpiece rotates rather than the drill bit.

In computer numerical control (CNC), machine tools are also called peck drilling or interrupted cut drilling. It is used to keep swarf from detrimentally building up when deep holes.

This peck drilling involves plunging the drill partway through the material, which is more than five times the diameter of the drill. It then retracts it to the surface, which is repeated until the cutting is completed.

Hand-Feed and Power-Feed Drilling Machine

Hand-feed Drilling Machine

The hand-feed types of drilling machines are simple and common types used in most workshops today. It is portable and a light-duty machine that is hand-fed by man’s power, using the handle. The operator can feel the action of the cutting tool as it cuts through the workpiece.

These drilling machines are available as bench- or floor-mounted, and they are driven by electric motors. This electric motor turns the drive belt on a pulley that connects to the spindle pulley. A hand-fed drilling machine is essentially high-speed and is used on small workpieces.

The sizes of holes drilled with these machines are ½ inch or smaller. The head can move up and down on the column by loosening and locking the chuck. This allows the drilling machine to drill different types of heights of work.

You should also learn about CNC rapid prototyping with this detailed guide!

Power-Feed Drilling Machine

The power feed drilling machine is used in a maintenance workshop for medium-duty work or work that requires large drills. These machines are usually larger and heavier than the hand-fed ones. They are designed with the ability to feed the cutting tool into the work automatically. The depth can also be set at a preset to cut per revolution of the spindle at thousandths of an inch per revolution.

The capability of power-feed drills is needed for drills or cutting tools that are over ½ inch in diameter. This is because they require more force to make the hole than the force provided by hand. Speed varies from about 50 rpm to about 1,800 rpm in power-feed drills. special operations like counterboring, countersinking, reaming, etc., are achieved with slower speed.

The sizes of this type of machine range from 17-inch to 22-inch center drilling capacity. They are usually floor mounted and they can be up to 2 inches, which is mounted into tapered Morse sockets. T-bolts and clamps are used to clamp larger workpieces directly to the table or base. While smaller workpieces are held with a vise.

Power transmission in a drilling machine is used to transmit power for its work; this power is supplied from the electric motor. The transmission process happens with the help of a V-belt and pulley stacks, which connect the motor and the spindle. adjustment in the mechanism also helps to generate different speeds for the spindle.

Learn about Power-Feed and Hand-Feed Drilling Machine with this detailed guide!

The Feed, Cutting Speed & Machining Time of a Drilling Machine

In the operation of a drilling machine, the feed, cutting speed, and machining time are important to achieve the desired result. Operators are expected to know the equation of these terms.

Feed

The feed is the distance a drill bit travels into the workpiece with each rotation. It is also called feed rate and is mostly measured in millimeters. The range of the feed is 0.05 to 0.35 mm. A drill bit can be maintained by employing the best feed rate, which, to a layman, is by not feeding too hard or too low.

Cutting Speed

The cutting speed is the rate at which the edge tool travels through rotation. Materials are highly impacted by the drill bit cutting speed, which is why cutting speed should be considered and recommended. The cutting speed typically ranges, depending on the material, from 10 m/min to 90 m/min. This can have an impact on how much material is removed.

Mathematically, v=πdN1000

Here,

v = Cutting speed, in m/min

d = Drill diameter, m

N = Number of rotations of cutting tool per minute

Machining Time

The machining time is the total time taken by the drilling machine to achieve the desired hole on the workpiece. It can be calculated using

T=LN×f

Here, f = feed in m.

Learn about NC machining with this detailed guide!

Maintenance and Safety in Drilling Machine

One of the major maintenance tasks for a drilling machine is lubricating in between the drill bit and workpiece while working. This helps to dissolve heat and friction generated by the moving parts. Some manufacturers offer manuals for proper lubricating methods and cleaning methods.

The drilling machine is expected to be cleaned after use and clear the chips to avoid damage to the moving parts. Ensure spindles and sleeves are free from grit to avoid damaging the precision fit. To prevent rust on the machine parts, especially the bed, the oil should be lightly coated on their surfaces.

Drilling larger holes requires some special care to avoid injuries to the operator. The part should hold one vise or join with other metal parts that will stop the workpiece from moving. It should be operating at slow speeds to avoid rapid abrasive wear on the moving parts. Lubrication should also be added more often.

When the machine is in extremely cold conditions, the machine should work at a slow speed. Allow the parts and lubricants to warm up before increasing the speed.

Safety precautions are to be taken in drilling operations, as they involve power equipment. It must be considered to prevent damage to the equipment, operator, and people nearby. To avoid this, serious care must be taken in maintaining and setting up the work and proper working tools should be selected. The holding device should also be in good condition to avoid damage.

Advantages of Drilling Machine

Below are the benefits of a drilling machine:

- Drilling machines are much faster than manual drills.

- They are designed to be precise and accurate with consistent size and depth.

- Modern drilling machines are automated; they are capable of making large holes of consistent size, shape, and depth.

- They are used to drill different materials like plastics, wood, metal, and composites, which is why they are used in various applications and industries.

- The machines are capable of drilling different sizes of holes on different workpieces.

You should also learn about Ultrasonic Machining with this detailed guide!

Disadvantages of Drilling Machine

Below are the limitations of drilling machines:

- Drilling machines can be so noisy and produce vibration.

- Drilling machines have limited depth of drilling

- Operator are exposed to injury if not careful

- Machine can be expensive to purchase and maintain

- Regular maintenance is required to prevent breakdown

Conclusion

A drilling machine is a versatile and essential tool used in manufacturing, construction, and workshop environments to create precise round holes in various materials. From bench-type drills to radial and CNC drilling machines, they come in different forms tailored to specific tasks.

The efficiency of a drilling machine depends on the correct selection of drill bits, speed, and feed rate for the material. Regular maintenance and adherence to safety measures ensure long-term reliability and optimal performance.

Also learn about Chip Formation with this detailed guide!

FAQs on Drilling Machine

What is a drilling machine?

A drilling machine is a power-driven tool used to create or enlarge cylindrical holes in solid materials using a rotating drill bit.

What are the types of drilling machines?

Common types include bench drilling machines, pillar drilling machines, radial drilling machines, gang drilling machines, and CNC drilling machines.

What materials can be drilled using a drilling machine?

Metals, wood, plastic, ceramics, and composites can be drilled depending on the drill bit and machine used.

How do you select the right speed for drilling?

Speed is chosen based on the material and hole size. Softer materials and smaller holes require higher speeds; harder materials need slower speeds.

What are the safety precautions when using a drilling machine?

Wear protective gear, secure the workpiece, avoid loose clothing, and keep hands clear of rotating parts.

What is the function of the feed mechanism in a drilling machine?

The feed mechanism controls the downward movement of the drill bit into the material, affecting cutting efficiency and accuracy.

How do I maintain a drilling machine?

Regularly clean the machine, lubricate moving parts, check for wear, and inspect drill bits for sharpness.