A camshaft position sensor is found in every modern automobile. This sensor is an essential component of any car since it ensures that the engine is operating correctly. When looking under the hood of your car, you can have problems finding the sensor.

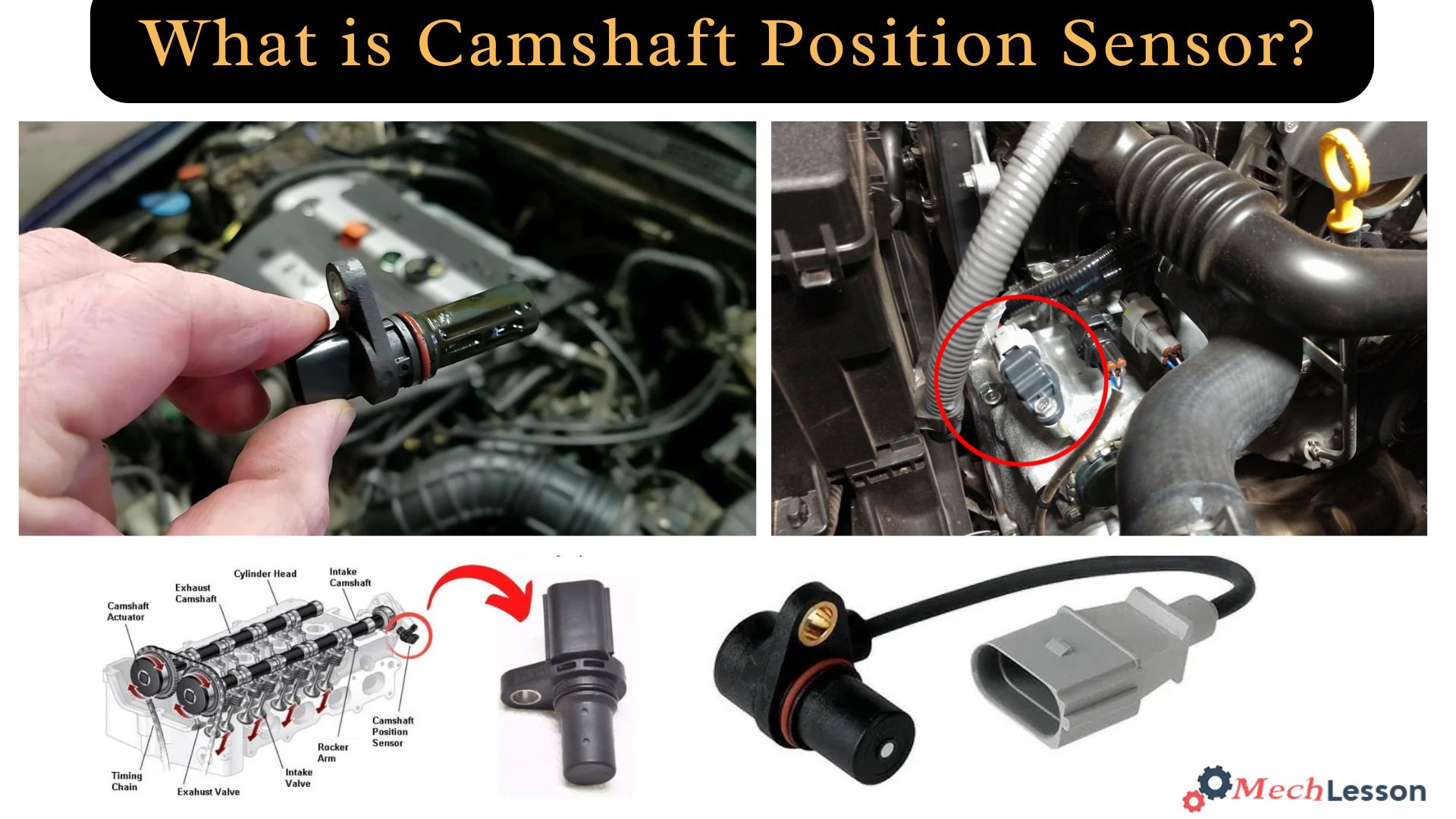

Typically, each car manufacturer will have its unique location for putting the sensor near the engine. It can be found behind the cylinder head, in the vehicle’s lifter valley, or adjacent to the engine block.

A camshaft position sensor’s job is to figure out where the camshaft is with the crankshaft. The powertrain control module (PCM) receives this information and uses it to operate the fuel injectors and/or ignition system. Well, in this reading, you’ll learn what a camshaft position sensor is, its functions, diagram, and how it works. We’ll also explore its symptoms and crucial FAQs.

Let’s begin!

Learn about camshafts with this detailed guide!

What is a camshaft position sensor?

The camshaft position sensor keeps track of the camshaft’s rotation, focusing on when valves open and close. The majority of camshaft sensors are located right above the camshaft’s notched ring.

The majority of these camshaft sensors will employ a magnet to generate or alter an AC electrical signal, which will be utilized in conjunction with a crankshaft position sensor to determine when a position approaches the top dead center (TDC) on the compression stroke.

This data will aid in the fine-tuning of spark timing and injector pulse. it is also called a cylinder identification sensor or phase detector.

The ECU in a sequential fuel injection system must decide which cylinder to ignite next. The cylinder identification sensor provides this information. Whenever the first cylinder is at the top dead center during engine rotation, the sensor transmits a signal to the onboard controller (TDC).

Functions of Camshaft position (CAM) sensor

The following are the common functions of a camshaft position sensor:

To determine which cylinder is on its power stroke, a camshaft position (CMP) sensor is used by the car’s computer to monitor the rotating position of the camshaft relative to the crankshaft position. This information will be used to alter the spark timing and fuel injector operation.

The CAM sensor, also known as the camshaft position sensor, is responsible for informing the ECM of the camshaft position. The crank and cam sensors are in time with one another. In a sequential system, the CAM sensor is typically employed to determine which injector to fire and for the COP or coil-on-plug ignition system coil firing event.

The camshaft position sensor collects and communicates data on the vehicle’s camshaft speed to the engine control module (ECM). This information is used by the ECM to determine the ignition timing as well as the timing of the fuel injection required by the engine. The engine would not be able to work effectively without this information.

You should also learn about crankshaft with this detailed guide!

Diagram

How Does a CAM Sensor Work?

The working of a camshaft position sensor is less complex and can be easily understood. just as stated earlier, The ECU in a sequential fuel injection system must decide which cylinder to ignite next.

The cylinder identification sensor provides this information. Whenever the first cylinder is at the top dead center during engine rotation, the sensor transmits a signal to the onboard controller (TDC).

As a result, the duration of the pulse injection may be calculated. The onboard controller in simultaneous fuel injection systems does not identify the cylinders or the firing sequence because it is not required for the system to function.

The exact cylinder is determined when a crankshaft or distributor advance ignition signal comes by detecting the mechanical locations of the crankshaft, camshaft, valves, or distributor shaft.

Learn about The Difference Between Lean Burn and Rich Burn Engine with this detailed guide!

Common Symptoms of a bad camshaft position Sensor

The following are the symptoms you experience when a camshaft position sensor is faulty:

The check engine light is on:

When your camshaft position sensor fails or starts to malfunction, the first thing you should notice is that your dashboard’s “Check Engine” light illuminates. Obviously, the “Check Engine” light could signal a lot of issues, including a malfunctioning camshaft position sensor.

Ignition Problem:

If the camshaft position sensor fails while you’re driving, the engine will occasionally lose power, causing your car to shake or surge forward at random. These are both caused by the PCM receiving inaccurate information from the camshaft position sensor, resulting in an incorrect quantity of fuel being pumped into the cylinders.

Engine Stalling:

Even worse than not being able to start your automobile is having your engine shut down or stall while driving because the fuel injectors aren’t being told to feed fuel into the cylinders.

Poor Acceleration:

When your camshaft sensor begins to fail, your vehicle will jerk and be unable to accelerate quickly. In certain circumstances, you’d be lucky if you got past 30 miles per hour. Incorrect fuel supply by the injectors is again to blame for the weak acceleration.

Problem Shifting:

Certain models of cars with a faulty camshaft position sensor will develop a locked transmission, which will remain in a single gear. The only way out of that gear is to turn off your engine, wait a few moments, and then restart.

Bad Fuel Mileage:

This is the opposite of not giving the engine adequate gasoline. Because of an inaccurate reading from a malfunctioning camshaft position sensor in this situation, more fuel is pumped into the engine than is required, lowering your fuel economy.

You should also learn about The Various Car Smells and What Causes Them with this detailed guide!

Conclusion

The camshaft position sensor is a vital component of a vehicle’s engine management system. It monitors the position and speed of the camshaft, sending data to the engine control unit (ECU) to optimize ignition timing and fuel injection.

A camshaft position sensor keeps track of the camshaft’s rotation, focusing on when valves open and close. The majority of camshaft sensors are located right above the camshaft’s notched ring.

The majority of these camshaft sensors will employ a magnet to generate or alter an AC electrical signal, which will be utilized in conjunction with a crankshaft position sensor to determine when a position approaches the top dead center (TDC) on the compression stroke.

A properly functioning camshaft sensor ensures smoother engine performance, better fuel efficiency, and reduced emissions. When faulty, it can lead to engine misfires, poor acceleration, stalling, or even failure to start. Regular diagnostics and timely replacement of a failing sensor can help maintain engine health and performance.

Learn about superchargers with this detailed guide!

FAQs on Camshaft Position Sensor

What is the function of a camshaft position sensor?

It monitors the camshaft’s position and rotational speed to help the ECU control ignition timing and fuel injection.

What are the symptoms of a bad camshaft position sensor?

Common signs include engine misfires, difficulty starting, poor acceleration, rough idling, and the check engine light turning on.

Can I drive with a faulty camshaft position sensor?

While the vehicle may still run, prolonged driving can lead to performance issues and potential engine damage.

Where is the camshaft position sensor located?

It’s usually mounted near the top or front of the engine, close to the camshaft gear or timing cover.

How is it different from a crankshaft position sensor?

The camshaft sensor monitors camshaft position for valve timing, while the crankshaft sensor tracks crankshaft rotation for piston timing. Both work together for proper engine synchronization.

How much does it cost to replace a camshaft position sensor?

Replacement costs typically range from $100 to $250, including parts and labor, depending on the vehicle model.