An internal combustion engine’s combustion chamber is where the fuel, air, and gas turbine are burned at a steady temperature. The air is then expanded to produce energy. The phrase has also been used to refer to a firebox extension used in steam engines that permits a more thorough combustion process.

The pressure generated by the burning air/fuel mixture in an internal combustion engine exerts direct force on a portion of the engine (for example, the top of the piston in a piston engine), which transforms the gas pressure into mechanical energy (typically in the form of a rotating output shaft).

Well, in this reading, we’ll explore what a combustion chamber is, its functions, diagrams, and types.

Let’s begin!

Learn about Engine Air Filter with this detailed guide!

What is Combustion Chamber?

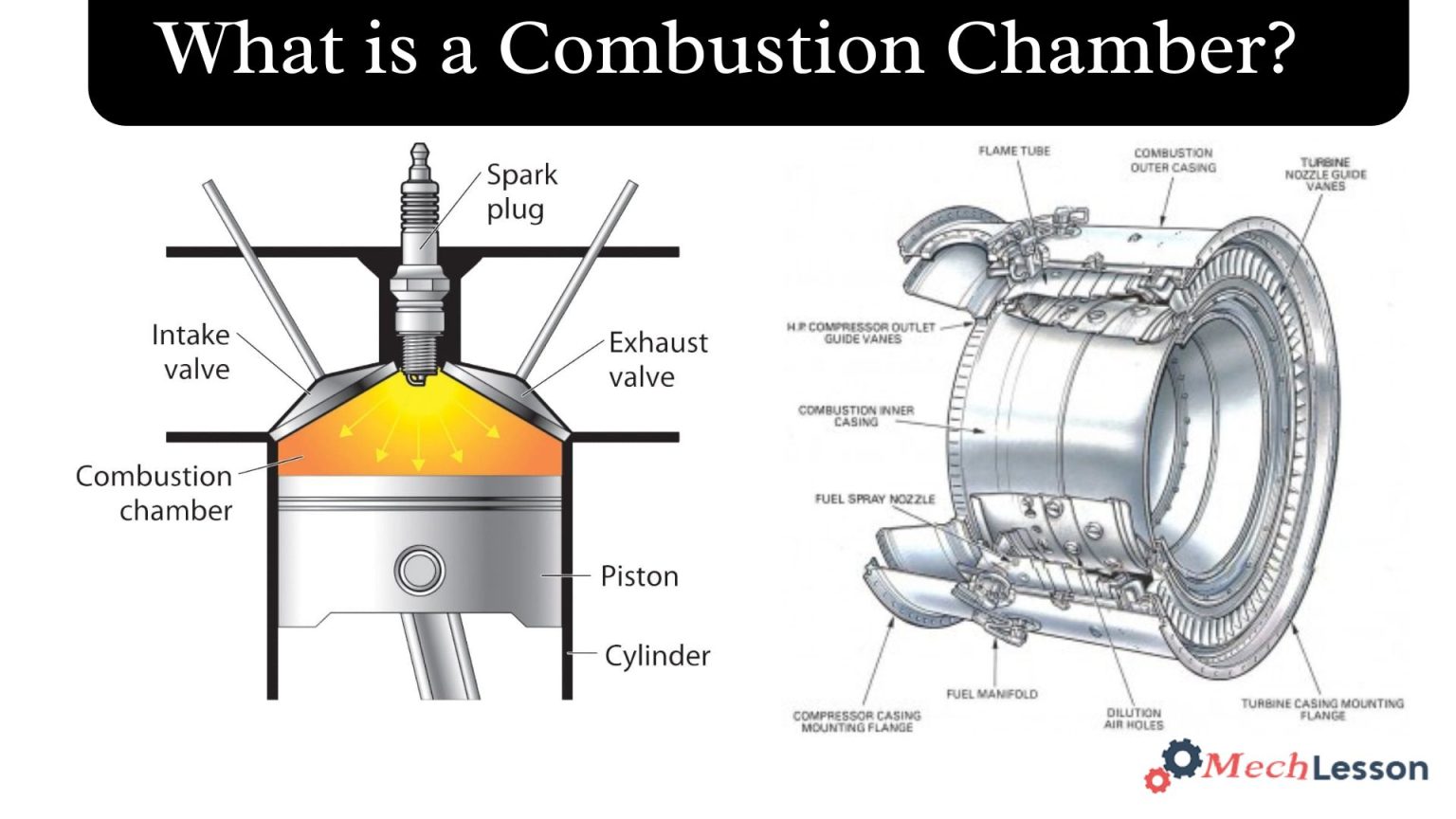

A combustion chamber is a part of the cylinder where the fuel/air mixture is ignited. Energy is released from the combustion chamber when the mixture burns as the piston compresses the fuel/air combination and comes into contact with the spark plug.

Numerous crucial parts of an internal combustion engine, such as the combustion chamber, piston, spark plug, injector nozzle, and others, are housed in the cylinder. The hot gas required for the drying process is produced in the combustion chamber.

Steam is used to first heat the heavy fuel to 100 °C. A ventilator in the combustion chamber injects the main air under low pressure, producing the oxygen required for burning. A secondary air current carries the generated heat into the drying tube.

Functions

- It provides confined space for air and fuel mixture combustion.

- The houses have inlet & outlet valves for mixtures incoming and outgoing.

- It guides pistons and aids in proper combustion geometry.

- It resists high combustion temperatures.

- It prevents combustion exhaust spillout.

Diagram

You should also learn about Air Suspension System with this detailed guide!

Types Of Combustion Chamber

The following are the main types of combustion chambers:

- Annular Combustion Chamber.

- Tubo-annular Combustion Chamber

- Multiple Combustion Chamber.

Annular Combustion Chamber

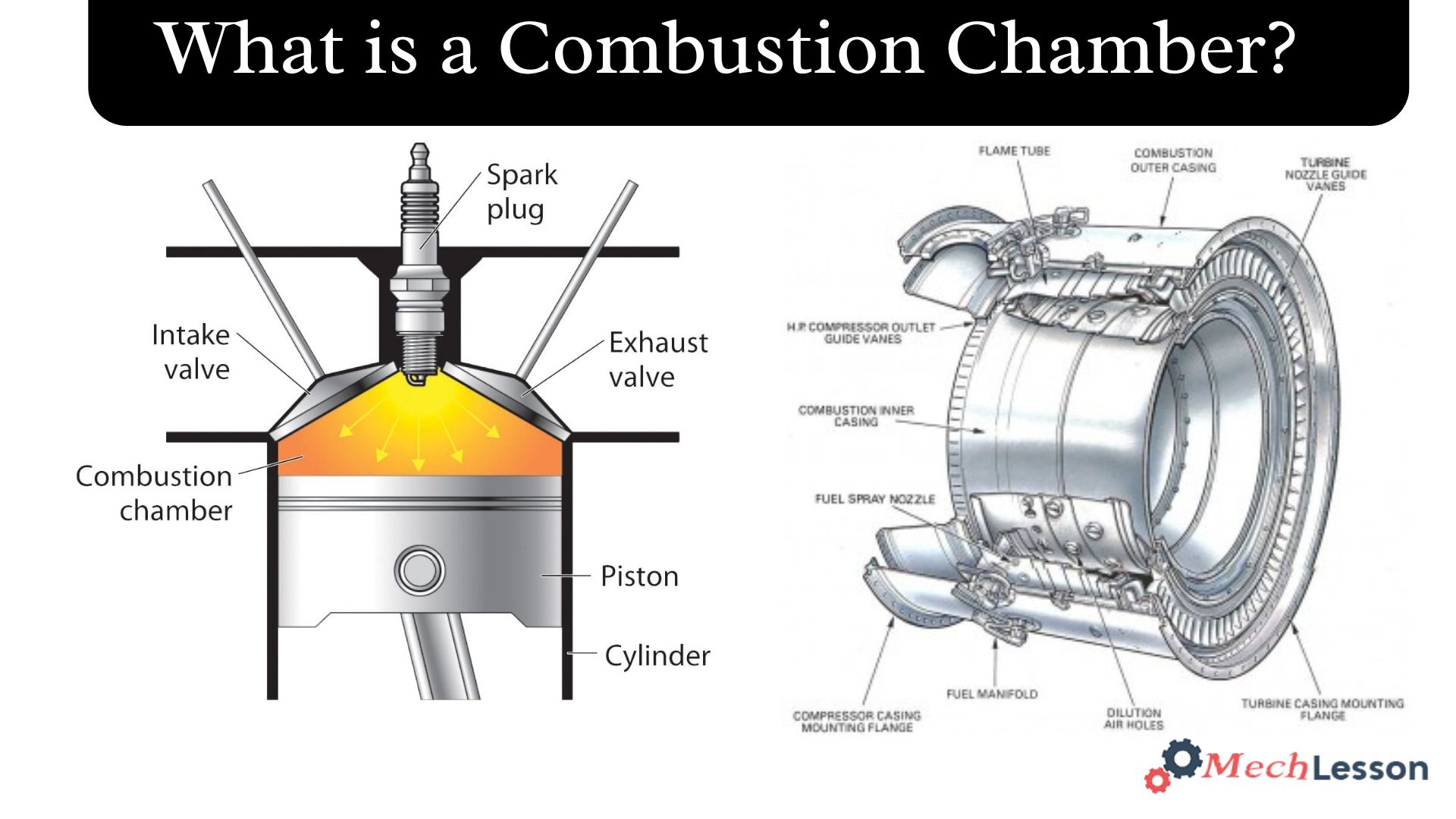

An annular combustion chamber is a kind of combustion chamber that is made up of a single, fully annular flame tube that is enclosed by both an inner and an outer shell.

With the chamber open at the front to the compressor and the rear to the turbine nozzles, the airflow through the flame tube is comparable to that previously mentioned.

The annular chamber’s primary benefit is that it is only 75% longer than a tubo-annular system of the same diameter for the same power output, which results in significant weight and production cost savings. The removal of issues with combustion propagation from chamber to chamber is an additional benefit.

A similar annular chamber’s wall area is significantly smaller than that of a tubo-annular combustion system; as a result, 15% less cooling air is needed to keep the flame tube wall from burning.

By oxidising carbon monoxide to harmless carbon dioxide and increasing combustion efficiency, this decrease in cooling air helps to reduce air pollution.

Tubo-annular Combustion Chamber

This type of chamber is an evolutionary divide between the multiple and annular types, and it is filled by the tubo-annular combustion chamber. Several flame tubes are installed within a single air enclosure.

The airflow resembles the previously reported one. This configuration combines the annular system’s compactness with the ease of testing and overhauling the multiple systems.

Multiple Combustion Chamber

This multiple combustion chamber compresses the engines, and the older axial flow compressor engines both employ this kind of combustion chamber. It directly evolved from the original Whittle combustion chamber type.

The main distinction is that Joseph Lucas Limited constructed the straight-through multiple chambers, but the Whittle chamber had a reverse flow, as shown, which resulted in a significant pressure loss.

Compressor supply air is guided by ducts into the different chambers, which are arranged around the engine. There is an air casing around the inner flame tube of each chamber. As previously mentioned, the air travels through the flame tube’s nose and between the tube and the outer casing.

Learn about Indirect Injection System with this detailed guide!

FAQs

What is the function of combustion?

Combustion, also known as burning, is the basic chemical process of releasing energy from a fuel and air mixture. In an internal combustion engine (ICE), the ignition and combustion of the fuel occur within the engine itself. The engine then partially converts the energy from the combustion to work.

What are the 3 main combustion chamber types?

Multiple Combustion Chamber.

Tubo-annular Combustion Chamber.

Annular Combustion Chamber.

What is the combustion chamber responsible for?

A combustion chamber is a component of a propulsion system that consists of several parts, including the injector assembly, the grain compartment, the aft mixing chamber, the nozzle, and the thrust vector control. Its purpose is to facilitate the combustion process for efficient propulsion.

What is the combustion chamber in a boiler?

As the name suggests, a combustion chamber is the part of a boiler in which the fuel/air mix burns. For this reason, the combustion chamber is usually cast iron, and the temperatures inside will rise to several hundred degrees. This process usually occurs in a very short amount of time