In the machining process, surplus material is progressively cut away from a prefabricated blank by shearing it into chips. To compress the work material and shear the surplus layer of material, a cutting tool—a stiff, hard, wedge-shaped device—is used.

Therefore, a cutting tool, also known as a cutter, is used to compress a specific layer of work material so that it may be sheared off. For smooth and effective material removal with the least amount of force, the cutter must have a wedge shape and a sharp edge. The material used for the cutter should also be robust enough to endure severe rubbing that occurs during machining.

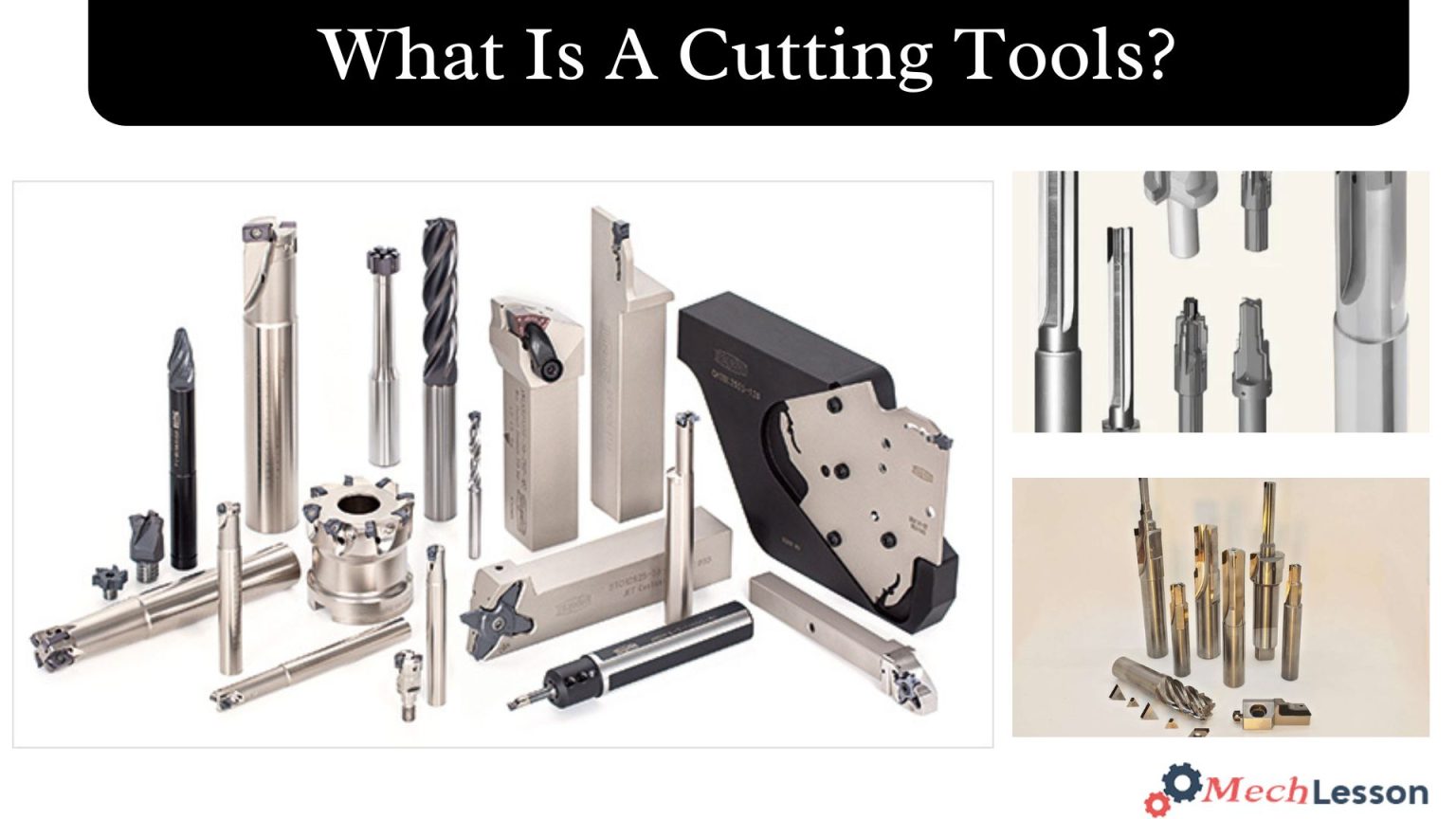

Well, in this reading, we’ll explore what cutting tools is, their types, diagrams, and materials.

Let’s begin!

Read about Punch Tools with this detailed guide!

What Is A Cutting Tool?

A cutting tool is a sharp-edged, wedge-shaped instrument used in machining to shear away extra layers of material from a workpiece in order to achieve the required size, form, and precision. The machine tool has it fixed firmly. Various mechanical and other cutting action designs also give a relative velocity between the workpiece and the cutting tool.

Most of these tools are made specifically for metals. Single-edge cutting tools come in a number of varieties, each constructed from a distinct hardened metal alloy that has been ground to a precise shape to carry out a particular turning operation and produce a final machined item.

In order to control the cutting tools and cut the material into the correct form, they are kept stable by a device called a tool post. Metal shaping and planning machines also use single-edge cutting tools to cut materials. These machines use a single cutting edge to remove material.

Diagram

Types Of Cutting Tools

Here are the main types of cutting tools:

Read about Laser Cutting with this detailed guide!

1. Single Point Cutting Tools:

A single-point cutting tool is made up of a single primary cutting edge that can remove material in a single pass. For tasks like turning, shaping, and planning, single point cutting instruments are employed.

Hard materials, including diamond, ceramic, high-carbon steel, and high-speed steel, are used to make it. With single-point cutting tools, the cutting edge is more likely to break, and the material may not be removed as rapidly since only one cutting edge is doing all the work.

You have to stop using the instrument and replace it completely if one of the cutting blades breaks while you’re using it. A single cutting edge is all that is used in single-point instruments, such as a single-bladed reamer, to remove material. Because only one edge performs the task, single-blade reamers can take longer.

Single-point cutting tools have the primary benefit of being relatively inexpensive, easy to design and produce, and requiring less time. Another drawback of the single cutting edge is that it stays in continuous touch with the workpiece while being machined.

Tool wear is high, and tool life is limited as a result. The constant contact causes the tool’s temperature to rise quickly. This promotes tool wear on the one hand, and damages the final surface thermally on the other.

Poor machining precision may result from the tooltip being plastically deformed by a significant temperature increase. The material removal rate (MRR) is significantly cheaper since just one cutting edge needs the full depth of cut (chip load) for a single run. Productivity is hence poor.

2. Double Point Cutting Tool:

Two cutting blades that may simultaneously cut or shear in a single action make up a double-point cutting tool. A single-point cutting tool, on the other hand, has just one primary cutting edge. In order to do machining tasks in a single pass, a multi-edged cutting tool has more than two cutting edges.

When double-point cutters are also referred to as multi-point cutters, there are instances in which cutters can only be categorised into two types. Furthermore, the junction of a flank and a rake face yields a cutting edge. Thus, double-point cutting tools have two sides and two rake faces.

Read about Chisel with this detailed guide!

The only example of a double-point cutting tool in this category is the drill. Keep in mind that drills might have more than two ends. Nonetheless, traditional metal cutting drills with no cutting edge modification have two cutting edges.

Two cutting edges acting simultaneously can occasionally provide a certain cutting force component in which the two edges automatically remove (or diminish) one another. This lessens a variety of shocks from an uneven cutting force, including vibration, instability, etc.

3. Multi-Point Cutting Tools:

More than two primary cutting blades that operate concurrently in a single pass are found in a multi-point cutting tool. Occasionally, two-edged cutters are also considered multi-cutting instruments (instead of double-point cutters). A multi-point cutter can have anything from three to several hundred cutting edges.

A multi-point cutting tool enables the simultaneous use of many cutting edges, unlike a single-point tool. Finally, the multi-point tool enables the removal of material from numerous tool edges simultaneously. This makes it possible for “multi-blade” or multiple cutting instruments to operate more quickly than single cutting tools.

The tool may frequently last longer and be more wear-resistant because the heat produced at the cutting edges is dispersed throughout all of the cutting blades. Multi-cutting tools like the Diatool high-performance reamer are excellent examples.

A multi-bladed reamer can improve quality and reduce cycle times when compared to other techniques. Low chip load per tooth, increased speed and feed, high MRR, and productivity are just a few benefits of multi-point cutting tools. Other benefits include less tool wear, low cutting temperature, and extended tool life.

Additionally, it has drawbacks like sporadic cuts, sharp edges, or teeth subjected to varying stresses. As a result, the cutter will make sounds, vibrate, and eventually fail. The cutter is rather challenging to design and produce. This raises the cost of such a cutter.

Read about Drill Bit with this detailed guide!

Cutting Tools Materials

A portion of the cutting tool stays in direct contact with the workpiece during machining, which results in high cutting temperatures and persistent rubbing. The cutting tool’s material needs to be able to withstand such high cutting temperatures and forces.

Certain qualities, such as high strength, high melting point, high hardness, high hot hardness, and chemical inertness even at high cutting temperatures, must be present in every tool material. For a smooth cutting action, the tool material’s hardness should, as a general rule, be at least 1.5 times that of the workpiece.

The instrument can also be coated appropriately to enhance a number of desired characteristics. However, when the edges of a coated tool wear down from extended usage, it is difficult to re-sharpen it by grinding. These days, there are insert-based tools that allow you to clamp or attach tiny, replaceable inserts to a big shank.

Due to their cutting action, these inserts progressively wear out. While the shank may be used again, the inserts can be changed out for new ones when wear reaches an acceptable level. Below is a list of some of the common tool materials found in today’s market.

- Steel High Speed (HSS) Tungsten carbide

- Cubic Boron Nitride (cBN) Diamond Ceramics

FAQs

What are the names of cutting tools?

Examples include alligator shears, abrasive saws, bandsaws, diamond saws, and milling machines. They can be classified as single-point or multiple-point tools, with single-point tools also capable of boring and enlarging holes.

What is the cutting tool?

Cutting tools are tools used to remove material from a workpiece in the form of chips. They are used in a wide range of manufacturing and machining processes, such as drilling, milling, turning, and grinding. The selection of cutting tools is crucial to the efficiency and quality of the machining process.

What are the examples of cutting tools?

Examples include turning tools, boring tools, fly cutters, slotting tools, etc. Double point cutting tool—As the name implies, these tools contain two cutting edges that simultaneously participate in cutting action at a pass. Example includes drill (common metal cutting drill that has only two flutes).

What is 3 cutting tools?

Cutting tools and equipment are instruments used for material removal from a workpiece by applying mechanical force. Basic functions of cutting tools include shaping, drilling, cutting, or slicing. Cutting tools range from simple scissors and knives to saws, cutters, and drills.