Engine valves, which are found in the engine’s head casting, are mechanically opened and closed to allow air to enter or exhaust gases to exit the engine cylinder or cylinders. The valve seat is the region where the valve seals against the head.

The component that modifies fluid flow, maintains its stretch with a spring, and rises and falls is the valve. In internal combustion engines, the valve controls how gas or liquid fuels move through a pipe system.

Well, in this reading, we’ll explore what a valve is, its functions, parts, diagram, types, and how it works. We’ll also explore the symptoms of a bad engine valve and its replacement costs.

Let’s begin!

You should learn about PCV Valve with this detailed guide!

What is Engine Valve?

Engine valves are mechanical components used in internal combustion engines to allow or restrict fluid or gas flow to and from the combustion chambers or cylinders during engine operation.

In internal combustion engines, the valve controls how gas or liquid fuels move through pipe systems. It alters the engine’s air intake alone or the fuel-air combination. With their mechanical motions, car valves control the engine’s fuel, air intake, and output.

Opening the intake valve allows the fuel-air mixture to enter the engine cylinder; opening the exhaust valve causes the fuel-air combination to burn out and generate exhaust gas. Burning takes place, and the cylinder’s integrity is guaranteed when both valves are closed.

The exhaust valve is used to release the gas that is released following this combustion process.

Regardless of whether they are powered by petrol, diesel, kerosene, natural gas (LNG), or propane (LP), many combustion engines contain engine valves. The number of cylinders—the combustion chambers that produce power from fuel ignition—varies between engine types.

The design positioning of the valves within the engine (overhead valve (OHV), overhead cam (OHC), or valve in block (VIB)) and the type of operation (two-cycle or four-cycle) also differ.

Overhead Valve

A piston engine with valves in the cylinder head above the combustion chamber is known as an overhead valve (OHV) engine. of contrast, the valves of early flathead engines were situated in the engine block beneath the combustion chamber.

In a standard OHV engine, the camshaft is housed in the engine block. To control the valves at the top of the engine, the camshaft’s motion is transmitted through rocker arms and pushrods.

Overhead valve engines that employ pushrods are sometimes referred to as “pushrod engines” to prevent confusion, even though an overhead camshaft (OHC) engine also features overhead valves.

A hybrid design that combined aspects of overhead and side valves was employed by several early “intake over exhaust” engines.

Note: The major function of an engine valve is to allow or restrict the flow of fluid or gas to and from the combustion chambers or cylinders during engine operation.

You should also learn about Check Valve with this detailed guide!

Parts

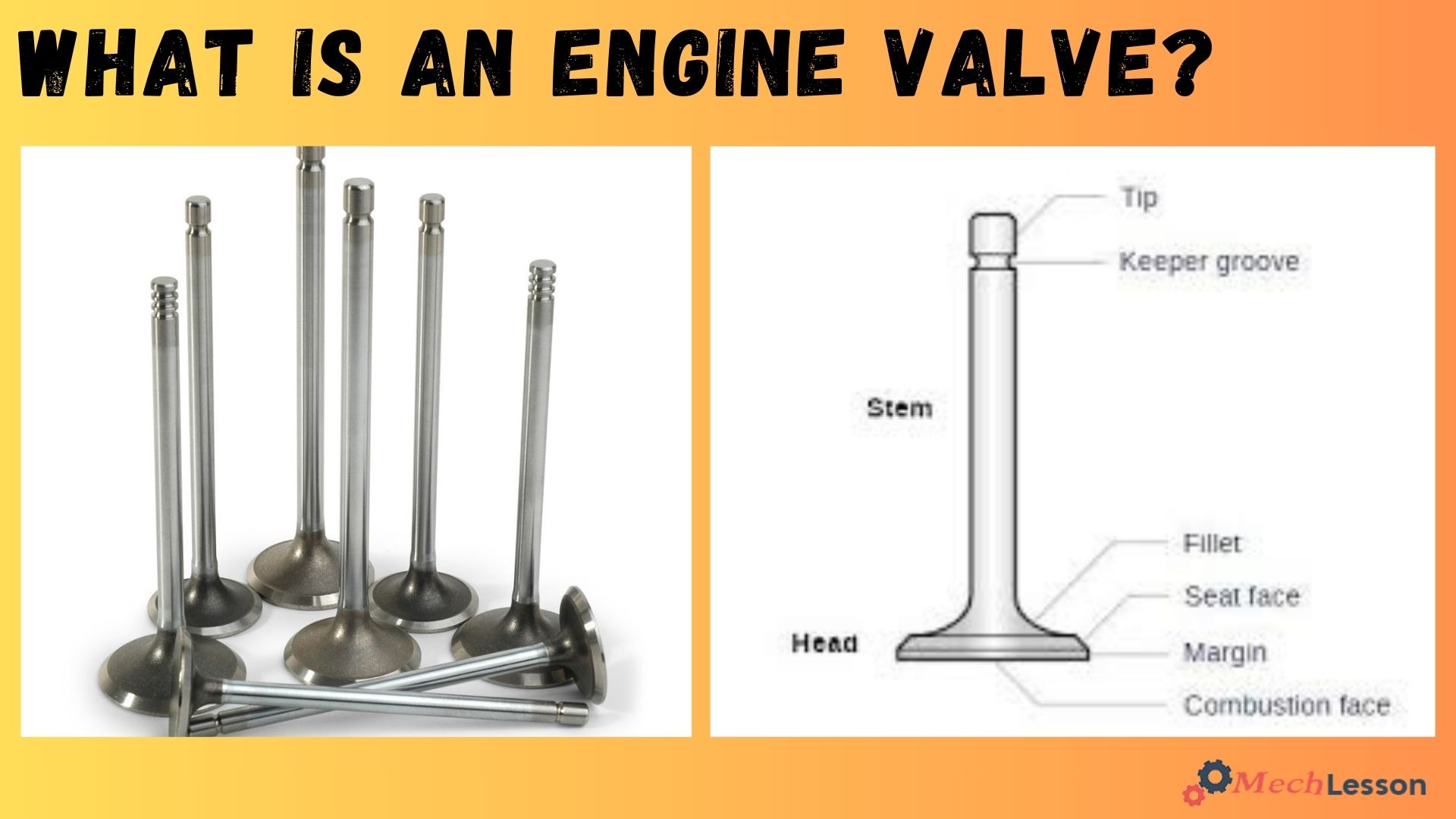

A valve has two major components, which include the head and the neck. The valve disc is directly facing the combustion chamber (also known as the valve head).

It is the circular component that functions in the cylinder to allow airflow by opening and closing when closed. This component needs to be strong and have enough wall thickness since it will be subjected to high temperatures, pressures, and mechanical impacts.

After grinding, the disc wall thickness cannot be less than 0.8 mm. The neck, which is filled and curved to prevent bending and breaking, is the area where the valve disc and valve stem meet.

Diagram

You should learn about ValveTrain with this detailed guide!

Types of Engine Valve

The three kinds of engine valves include rotary, sleeve, and poppet.

Rotary Valve

Rotating valves come in a variety of forms. The disc-type rotary valve is seen in the illustration. It is made up of a revolving disc with a port. It alternately interacts with the exhaust and intake manifolds while spinning.

Rotary valves are inexpensive to manufacture and have simple designs. They work well with high-speed engines. There are fewer strains and vibrations in these valves. The operations of rotary calves are quiet, consistent, and seamless.

Sleeve Valve

As the name suggests, the sleeve valve is a tube or sleeve that slides or rotates in the internal combustion engine’s cylinder between the piston and the cylinder wall.

These valves operate quietly and also have a simple design. Since there are no components that produce noise, such as rocker arms, tappet valves, valve cams, etc., there is noise. Sleeve valves are less likely to explode.

This is because the valve is in touch with water jackets; cooling is particularly effective.

Poppet Valve

Rotating valves also come in a variety of forms. The disc-type rotary valve is the most common. It is made up of a revolving disc with a port. It alternately interacts with the exhaust and intake manifolds while spinning.

Rotary valves are inexpensive to manufacture and have simple layouts. They work well with fast engines. There are fewer strains and vibrations in these valves. The operations of rotary valves are quiet, consistent, and seamless.

Learn about Piston with this detailed guide!

How Does an Engine Valve Work?

The engine valve operates by pear-shaped lobes called cams on a rotating shaft. The camshaft is driven by a chain, belt, or set of gears from the crankshaft.

The camshaft is mounted in the engine block, with small metal cylinder tappets in channels above each cam, and a metal pushrod extends up into the cylinder head.

The top of each pushrod meets a rocker arm, which bears against the stem of a valve, held in a raised position by a strong coiled valve spring.

As the pushrod rises on the cam, it pivots the rocker arm, pushing the valve down against the pressure of its spring. As the cam lobe rotates further, the valve spring acts to close the valve, known as an overhead valve (OHV) system.

Some engines have no pushrods, while others operate valves more directly by single or double camshafts in the cylinder head itself.

The overhead-cam (OHC) method is more efficient and produces more power for a given engine capacity than an engine with pushrods, as it can operate at higher speeds.

A preset gap tappet clearance is essential between the valve stem and the rocker arm or cam, allowing for expansion.

You should also learn about Piston Rings with this detailed guide!

Symptoms of a Bad Engine Valve

The symptoms of a bad engine valve include

- Engine Power Loss

- Noises From the Engine

- Blue Smoke from the Exhaust Pipe

Engine Power Loss

Low engine power and performance is a sign of valve damage. Valves are made to fit precisely, with little to no wiggle room. However, if there is an oil leak, a gap may emerge, and the valve would lose its seat.

Burnt valves can also result in power loss and a reduction in engine performance.

Noises From the Engine

Engine valve issues might be the cause of any popping or ticking sounds you hear from the engine. As you accelerate, the ticking noises usually become more audible.

This might be the result of a potential misalignment or worn-out valves. In either case, the engine’s lubrication may be compromised, which would explain the ticking sounds.

Blue Smoke from the Exhaust Pipe

Your car may have an engine problem if you notice blue smoke coming from the tailpipe. Engine valve issues might be one of the many issues caused by blue smoke.

Oil can enter the combustion chamber through damaged engine valve seals and guides. As a result, the gasoline and oil burn together. Additionally, drivers are more likely to notice a sudden drop in oil levels.

You should learn about Causes of Exhaust Leak with this detailed guide!

Causes of Engine Valve Problem

Below are the common causes of a bad engine valve:

- Poor Installation of Valve springs

- Improper Valve Clearance Settings

- Poor Installation of Hydraulic Tappets

- Worn Parts

- Combustion Error Resulting to OVerstressing Valve

- Valve Guide Misalignment

- Excess Valve Guide Clearance

Engine Valve Replacement Cost

Because of labor expenses, replacing a valve can be costly. A complete valve replacement can take a mechanic all day, depending on the engine’s size and kind.

The typical cost to replace a whole car valve is between $900 and $2,000. The cost to replace a single valve is between $100 and $200.

You should also learn about List of Auto Parts Names with this detailed guide!

FAQs

What is a valve in an engine?

Engine valves are essential components that control the flow of air and fuel mixture into the combustion chamber and allow the exhaust gases to exit. They consist of two main types: intake valves and exhaust valves.

What happens when an engine valve goes bad?

Signs of valve damage in an engine can include rough idling, misfires, or a noticeable loss of power, especially during acceleration. You may also hear a tapping or popping noise coming from the engine, indicating a potential issue with the valves not seating properly.

How many valves are in a 4-cylinder engine?

An example of this configuration can be found in many modern four-cylinder engines used in cars, where efficient airflow is essential for performance. These engines typically use 2 intake valves and 2 exhaust valves per cylinder, contributing to better combustion efficiency and power output.

How much does it cost to replace engine valves?

Replacing a burnt valve (or the entire cylinder head) is a costly and labour-intensive repair. If you choose to have a professional do the job, you can usually expect to pay somewhere between $1,000 and $2,500 to get the job done.

What causes engine valves to burn?

Exhaust valves burn when they fail to seat properly and, as a result, can’t efficiently transfer heat to the cylinder. Ultra-hot gasses scorch these valves beginning at their thin rims. This damage erodes and weakens the valves, exacerbates the poor seating problem, and dramatically accelerates wear.