Forklifts are trucks that are used on any job site because they can safely lift objects that humans cannot when moving heavy loads. Choosing the ideal forklift for your particular requirements can be challenging due to the large variety of styles and models available. One of the most adaptable vehicles for construction workers, warehouse employees, and others are forklifts.

Whether you’re looking to rent a forklift or purchase one for your next project, our guide covers the different forklift types, their benefits, and popular forklift models to help you choose the right forklift for your needs.

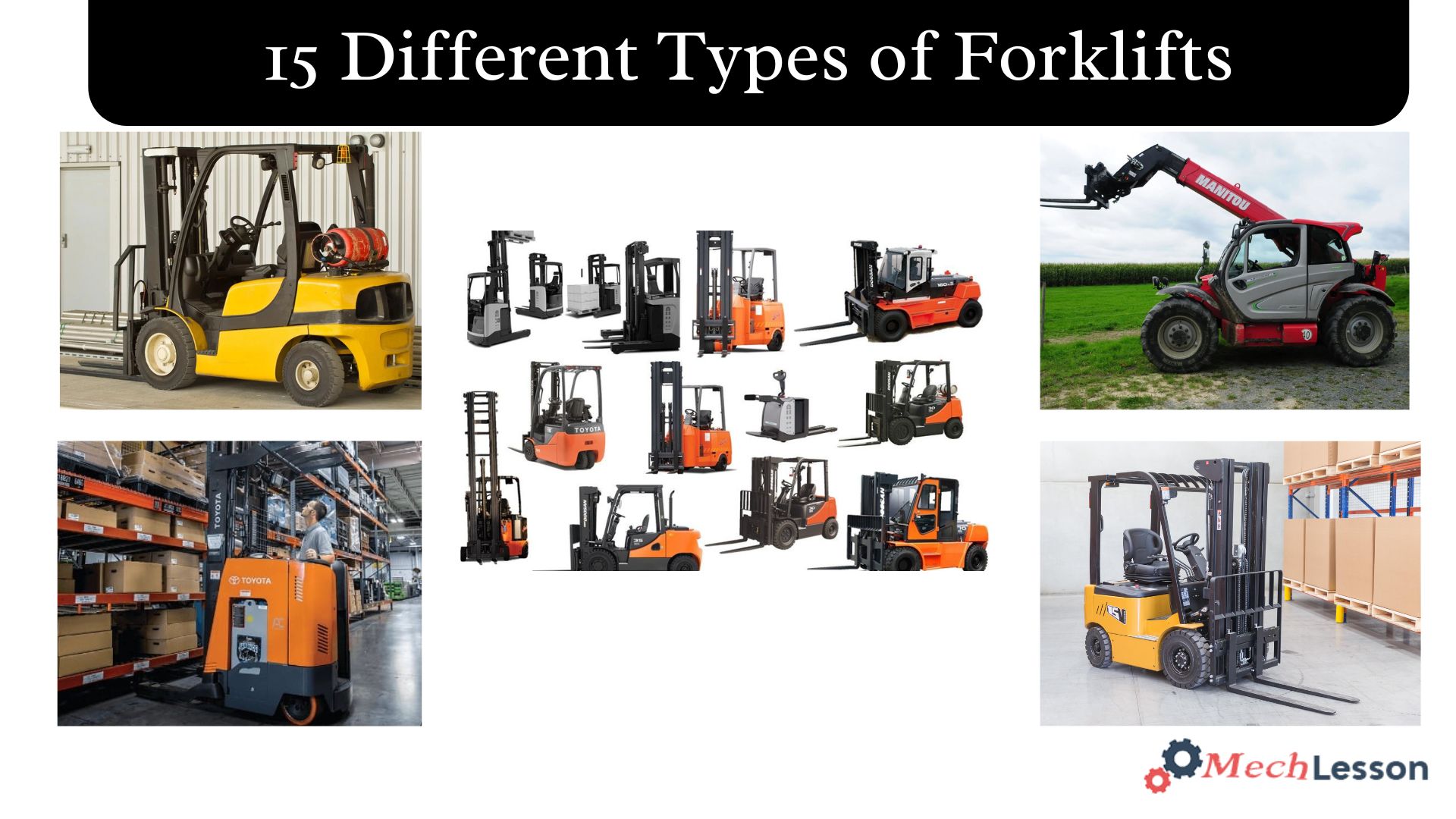

Well, in this reading, we explore what a forklift is, its diagram, 15 different types & their uses. We will also explore the elements of a forklift.

Let’s get started!

Learn about Servo Motor with this detailed guide!

What Is A Forklift?

Forklifts, often referred to as lift trucks or industrial trucks, are strong devices used in a range of warehouse and industrial environments to raise and transport large objects. Each of the many types and versions of these devices has a unique combination of characteristics and capabilities.

Early in the 20th century, a number of businesses, notably Yale & Towne Manufacturing, which produced hoists, and Clark, which produced gearboxes, invented the forklift. Forklift truck development and use have significantly increased globally since World War II. Forklifts are now a necessary piece of machinery for production and storage.

You may choose the kind of forklift you want to work on by being aware of the many kinds and their particular uses. A forklift qualification is necessary to operate the majority of these various forklift kinds.

Diagram

15 Different Types of Forklifts

Here are the following different types of forklifts and there uses:

- Counterbalance Forklift

- Reach Truck Forklift

- Order Picker Forklift

- Side Loader Forklift

- Telescopic Handler Forklift

- Rough Terrain Forklift

- Electric Forklift

- Pallet Jack Forklift

- Warehouse Forklift

- Industrial Forklift

- Marina Forklifts

- Pivoting-Mast Forklifts

- Articulated Forklifts

- Walkie-Stacker Forklift

- Telehandler Forklift

Counterbalance Forklift

Learn about Machine Design with this detailed guide!

Counterbalance forklift: this kind of forklift is the most often used and is intended for interior operation. It features a counterweight, or weight, at the back of the truck that helps balance the weight of the cargo being lifted. Counterbalance forklifts come in a number of sizes and may be used for a number of jobs, including lifting heavy gear, pallets, and stacks of boxes.

Reach Truck Forklift

Reach truck, This type of forklift is used in warehouses and distribution centres to store and retrieve goods from high storage racks. Their longer mast and smaller turning radius allow the operator to reach farther and lift higher, making them ideal for use in tight spaces and narrow aisles.

Order Picker Forklift

Order picker this kind of forklift is intended for use in picking and order fulfilment tasks. The operator may stand on the little platform at the top of the tower and retrieve objects from storage racks. Order pickers are usually employed to select and pack orders at distribution centres and warehouses.

Side Loader Forklift

Side loaders with narrow aisles and confined locations are ideal for using this kind of forklift. The operator can reach and lift anything from the side thanks to its side-mounted fork carriage and lower turning radius. In warehouses and distribution centres, side loaders are frequently used to store and retrieve goods from high storage racks.

Telescopic Handler Forklift

Telescopic handler, in building and agricultural environments are the intended applications for this kind of forklift. Its telescoping boom enables the user to lift and reach objects from a distance. Tasks like grading surfaces, digging trenches, and loading and unloading materials are frequently performed by telescopic handlers.

Rough Terrain Forklift

Rough terrain forklift, this forklift designed for outdoor and rough terrain applications,which is frequently utilised in mining, construction, and agriculture. Its large, robust wheels and strong engine enable it to manoeuvre through mud, gravel, and other difficult terrain.

Electric Forklift

Electric forklift This electric power powers this kind of forklift, which is intended for inside use. It is renowned for running quietly, producing little pollutants, and requiring little upkeep. In warehouses and distribution centres, electric forklifts are frequently utilised to store and move goods from high storage racks.

Pallet Jack Forklift

Pallet jack forklift this is a type of forklift it’s also named hand truck or pump truck. It is a compact, lightweight device made specifically for transporting pallets across a factory or warehouse. The handle may be pushed or pulled to operate it manually.

Warehouse Forklift

The warehouse forklift is the most often used in a facility with a lot of inventory. This warehouse forklift is the most recognisable type of lift truck. It looks like a yellow golf cart with twin forks extending from the front. These trucks are excellent for loading and unloading pallets and balanced materials as well as removing and moving items from delivery vehicles.

Industrial Forklift

The industrial forklift, often known as a big capacity forklift, combines the capabilities of a telehandler with a warehouse forklift. It can carry payloads far higher off the ground than a warehouse forklift and bigger loads, but it can’t reach awkward angles as a telehandler can.

The industrial forklift’s initial lift capacity is 30,000 pounds. However, only specialised occupations require such power. Compared to telehandlers and warehouse forklifts, the industrial forklift’s range of applications is more limited.

Learn about Hydraulic Motor vs Electric Motor with this detailed guide!

Marina Forklift

The marina forklifts are oversized lifts with long, rubber-coated prongs. Marina forklifts are designed to move boats in and out of towering storage racks while handling the corrosive nature of seawater. There are several different types of them, such as electric and diesel.

Pivoting-Mast Forklift

A pivoting mast forklift can swivel its mast at a 90-degree angle to its body, just like an articulated forklift. The sole distinction is that, unlike an articulated forklift, just the mast moves rather than the front tires.

Articulated Forklift

An articulated forklift, which is special because its mast can turn left or right independently of the truck body, is one way to solve the issue of narrow aisles in some operations that cannot hold a standard-sized forklift. This allows the operator to drive directly in the aisle and turn the mast at a 90-degree angle to access the material.

Walkie-Stacker Forklift

Walkie stackers have a peculiar look and a unique purpose. These material handling machines lack cabs, in contrast to other forklifts. Rather, the worker uses an attached handle to steer the stacker while walking behind it.

These devices lack speed, power, and manoeuvrability, much like a pallet jack. They are perfect, nevertheless, in cases when a larger pallet jack is required. Compared to its counterpart, the walkie stacker can reach far higher off the ground.

Telehandler Forklift

The telehandler, is also known as a reach forklift or telescopic forklift, combines a crane and forklift with its extending arm and boom. Pallets are raised off the ground using the twin prongs that are fastened to this arm.

5,500 pounds of items may be lifted by a regular telehandler up to 19 feet in the air. These material handling vehicles are excellent in reaching at strange angles and into confined locations.

Manufacturers such as JCB, Genie, Bobcat, Haulotte, and Caterpillar create a range of high-quality telehandlers due to their increasing popularity. Some types can lift items up to 55 feet high, while others, like the JLG 1644, are skilled at bigger capacity work.

Elements of Forklift

The main key elements of a forklift are: lift capacity, load center and stability. When selecting a forklift, it is important to consider the differences in capabilities across the various categories.

Learn about Lists of Best Floor Jacks with this detailed guide!

Lift Capacity: The weight a forklift can safely lift is known as its lift capability. Additionally, this sum is crucial to the stability of the car. Too much weight on a forklift makes it unstable.

Load Centre: The separation between the load’s centre of gravity and the forks is known as the load centre. The weight of the load, lift angle, and tilt angle all affect how much. As long as you maintain the load balanced and adhere to the specified weight capacity, you, as a forklift operator, don’t need to worry about the load centre.

Stability: The stability triangle, located beneath the forklift, keeps the vehicle’s centre of gravity stable, which is why you don’t have to worry about the load centre; the truck’s design takes care of it.

FAQs

What is a type 4 forklift?

Class IV forklifts are internal combustion engine cushion tire trucks. This class of sit-down forklifts is designed for indoor use. Class IV Forklifts are powered by internal combustion (IC) engines that run on diesel fuel, LP gas, gasoline, or compressed natural gas.2

What are the 5 names that a forklift is also known by?

A forklift (also called industrial truck, lift truck, jitney, hi-lo, fork truck, fork hoist, and forklift truck) is a powered industrial truck used to lift and move materials over short distances.

How many classes are there for forklifts?

There are seven basic types of forklift classes, ranging from class I to class VII. We’ll walk you through each class and explain the differences between each.

What is the most commonly used forklift?

counterbalance forklift

The counterbalance forklift is the most commonly used type, valued for its versatility across a range of industries.