A jig is a tool to secure a machine part and workpiece on a workstation. It is attached to CNC machine tools, including cutters, and controls their motion and position.

It’s simple to confuse the two terms fixtures and jigs. Although they are frequently used together, even though they serve comparable purposes. They cannot be used interchangeably.

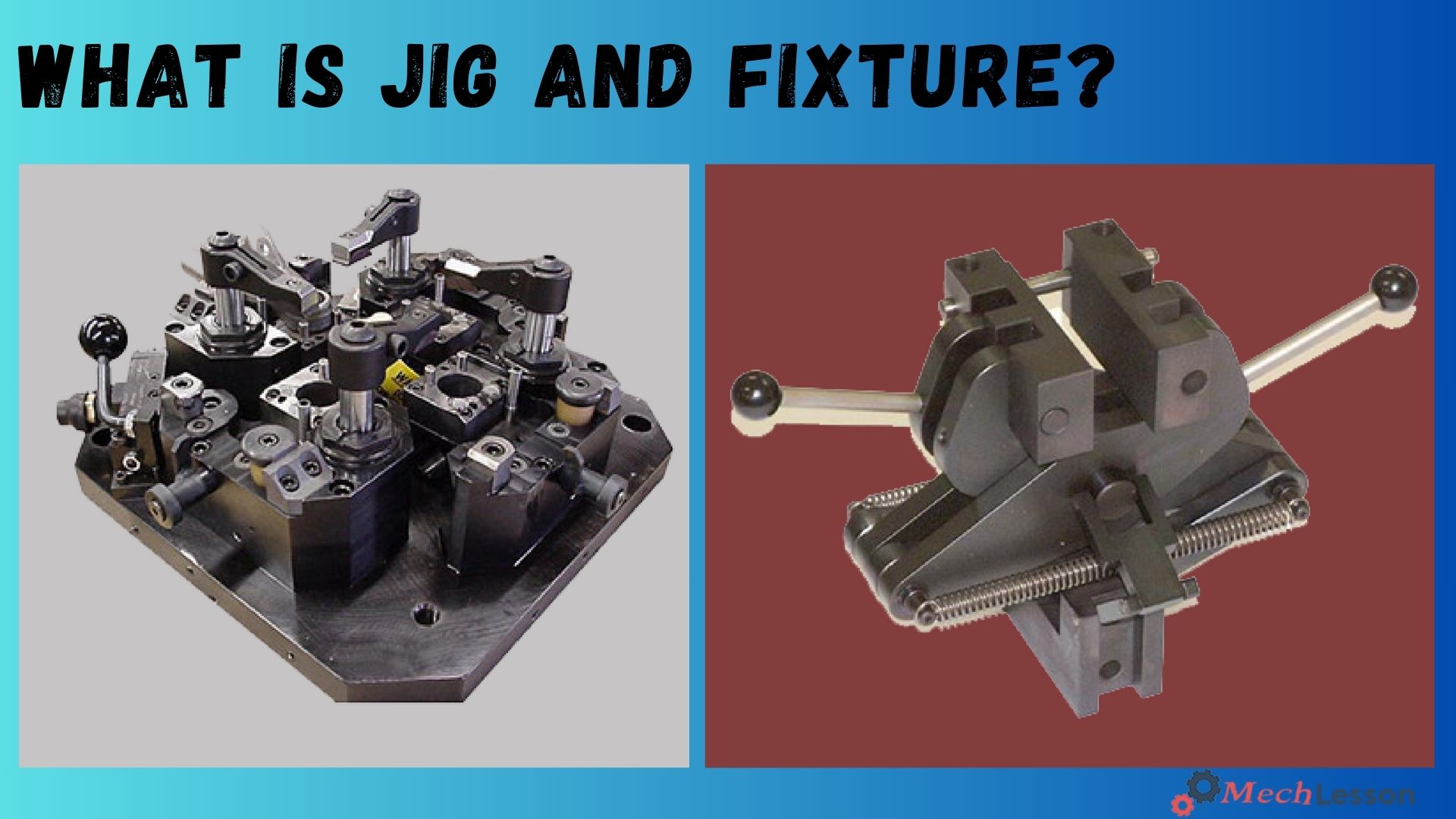

Well, in this reading, we’ll explore what jigs and fixtures are, their applications, diagrams, types, designs, and materials. We’ll also explore their advantages and disadvantages.

Let’s begin!

You should learn about Machining and Machine Tools with this detailed guide!

What is Jig and Fixture?

A jig is a tool to secure a machine part and workpiece on a workstation. It is fastened to CNC machine tools, including cutters, and controls their motion and position.

This implies that it functions as a type of guide for these machining tools. Jigs are special in that the tool becomes fixed while it moves.

Fixtures are often utilized in optical laser scanning inspection systems, automotive vehicle assembly, planning, slotting, milling, turning, and other multidimensional machining operations.

Fixtures also include a vise on a workstation and a material block secured within a CNC machine. In order to secure and direct automobiles throughout the welding and assembly process, fixtures are also important in an automotive assembly line.

Jigs are frequently used as tool or template guides or in drilling, reaming, counterboring, tapping, and other one-dimensional machining processes. Additionally, special clamping jigs that guarantee squareness are frequently employed.

A drill bushing, which aids in guiding a drill bit through the workpiece’s surface to guarantee proper alignment and angle, is another typical use for a jig.

Since the invention of automation and computer numerical controlled (CNC) machines, the tool path is digitally programmed and saved in the machine’s memory, negating the need for jigs.

Despite their differences, jigs and fixtures are both very useful tools. They boost output, enhance component repeatability, facilitate part assembly and disassembly, and contribute to a safer workplace.

Jigs and fixtures are essential to almost all automated industrial manufacturing processes in order to reliably produce parts that work as intended. By keeping these important factors in mind, engineers can ensure the strength and quality of their fixtures and jigs.

You should learn about The 9 Different Types of Vices with this detailed guide!

Applications

Jigs and fixtures are essential tools in various industries, including metalworking, welding, woodworking, automotive, electronics, aerospace, medical devices, and jewelry making.

They ensure precision in machining operations, ensuring accurate assembly and inspection of components. Jigs also aid in the manufacturing of automotive parts, electronics, aerospace components, medical devices, and intricate jewelry pieces, ensuring the safety and quality of the final product.

They are used in metalworking machining operations like drilling, milling, and grinding. Jigs and fixtures are also used in welding, as they help position and hold parts for welding. The component also aids in assembling various components accurately.

Jigs and fixtures ensure consistent inspection of parts of equipment. They are used in woodworking for precision take and are also essential in manufacturing various automotive parts like suspensions, tires, bearings, springs, chassis, etc.

In aerospace, jigs and fixtures help to ensure precision in aerospace component fabrication. They are also used in medical devices to assemble applications precisely.

Diagram

You should learn about The 12 Different Types of Spanners with this detailed guide!

Types of Jigs and Fixtures

In CNC machining, jigs are frequently used tools that come in a wide variety of forms. Fixture classification is unclear to the majority of machinists. This is why they struggle to choose the best one for their organization. Well, below are the common jig and fixture types used in machining processes:

Types of Jigs

The types of jigs include leaf jigs, plate jigs, angel-plate jigs, and template jigs.

Leaf Jigs—In this type of jig, the part loading and unloading is made simple by their hinged leaf. However, the section is not entirely encircled by the hinged leaf.

Plate Jigs—Plate jigs can be used in the same manner as template jigs. They do, however, contain integrated clamps to hold the workpiece.

Angle-Plate Jigs—These types of jigs are ideal when parts are ready to be drilled at an angle to their mounting locators.

Template Jigs—Because of their precision, these jigs are easy to use and perfect. They are also quite fast. But precision is more important to machinists than speed. There are several applications for template jigs. They can be fitted into, above, or on top of the workpiece.

Types of Fixtures

Below is the list of the various types of fixtures:

Fixtures Based on Their Power Source:

- Manual fixture

- Pneumatic fixture

- Hydraulic fixture

- Electric fixture

- Magnetic fixture

- Vacuum fixture

You should also learn about CNC Machine with this detailed guide!

Fixtures based on CNC machining operations:

- Turning Fixtures

- Milling Fixtures

- Drilling Fixtures

- Boring Fixtures

- Grinding Fixtures

Types of Fixtures Based on Their Applications:

- Universal Fixtures

- Special Fixtures

- Assembled Fixtures

- Modular Fixtures

- Combination Fixtures

Material and Design of a Jig and Fixture

The kind of operation, the nature of the workpiece, and finances all influence the material selection of a jig and fixture.

For jigs and fixtures to be long-lasting and functional, the materials used must have certain characteristics. Hardened steel, cast iron, aluminum, and even polymers like Delrin are typical materials.

Because of its remarkable strength and resistance to wear, hardened steel is frequently used for high-production settings. Cast iron is appropriate for machining fixtures because it provides stability and vibration damping.

When corrosion resistance or lightweight applications are required, aluminum is the material of choice. Because they lessen the chance of breaking fragile workpieces, plastics like Delrin are employed in non-marring or non-abrasive applications.

You should learn about Aluminum Machining with this detailed guide!

Design

The design and manufacturing process of a jig and fixture:

- CNC machining is the most common manufacturing method due to the low quantity of jigs and fixtures.

- 3D printing is recommended for complex or expensive geometry.

- Plastic can meet performance needs and save costs.

- Rapid manufacturing can be useful for creating less essential components like blanks for jigs and fixtures.

- CNC machining is recommended for frequently used fixtures or jigs.

- Rapid injection molding can provide 25–10,000+ components in engineering-grade thermoplastics for high-volume requirements.

When buying or manufacturing a jig and fixture, you must also understand the following:

- Understand the type and capacity requirement

- Know the loading and unloading arrangement

- Know the clamping arrangement and requirement

- Understand the power devices and safety arrangement devices. The component

- The locating elements

- Know the clearance between the jig or fixtures and their components.

- Understand the ejecting devices, table-fixing arrangement, and indexing devices.

Learn about Conventional Machining with this detailed guide!

Difference Between Jig and Fixture in Table Form

| Characteristic | Jig | Fixture |

| Purpose | Guides and directs the cutting tool | Holds and secures the workpiece in position |

| Function | Guides the tool and locates the workpiece | Holds and positions the workpiece |

| Primary Use | Drilling, reaming, or tapping operations | Milling, grinding, turning, or other operations |

| Weight and Construction | Lighter construction, often made from aluminium | Heavier construction, commonly steel or iron |

| Clamping | Usually not clamped to the machine table | Rigidly bolted or clamped to the machine table |

| Load-Bearing | Experiences minimal cutting loads | Supports heavy cutting forces |

| Key Features | Guide bushings, drill templates, and bushings | Clamps, supports, and locates workpieces |

| Typical Operations | Hole-making, precision drilling | Workpiece shaping, material removal |

| Machining Speed | Typically used for high-speed drilling | Suitable for various machining speeds |

| Examples | Drill jigs, reaming jigs, tapping jigs | Milling fixtures, grinding fixtures, turning fixtures |

You should also learn about Socket Sets and Wrenches with this detailed guide!

Advantages and Disadvantages of a Jig and Fixture

Jigs and fixtures are essential tools in manufacturing and machining processes, designed to improve precision, repeatability, and efficiency.

They increase productivity by eliminating frequent repositioning and checking, reducing operation time due to increased speed, feed, and depth of cut. They also enable the production of many workpieces with uniform quality and interchangeability at a competitive cost.

Jigs and fixtures also reduce skill requirements, as they allow unskilled or semi-skilled machine operators to set up workpieces, reducing labor costs. This results in higher production, reduced scrap, easy assembly, and savings in labor costs, ultimately reducing unit costs.

Advantages of jigs and fixtures also include enhanced machining accuracy, increased production capacity, reduced handling time, and higher machining speeds.

Also, they improve the feeds and depth of cut due to improved clamping rigidity and the production of identical, interchangeable parts for easier assembly.

Jigs and fixtures also eliminate manual marking out and measuring before machining, reduce operator labor and fatigue, provide accessibility for semi-skilled operators, decrease expenditure on quality control of finished products, and offer overall cost reduction through process automation.

However, jigs and fixtures also have disadvantages, such as initial cost, setup time, limited flexibility, storage and maintenance, and design complexity.

Designing effective jigs and fixtures requires specialized knowledge and engineering skills, which may be difficult and costly for small manufacturers without in-house expertise.

You should learn about Non-Traditional Machining with this detailed guide!

FAQs

What are jigs & fixtures?

A jig controls and guides the cutting tool to work at a predefined location on a workpiece. Fixtures are used to support and locate a workpiece. Fixtures do not guide the tool on a workpiece like a jig.

What is a jig used for?

Jigs are used in uni-dimensional machining processes like drilling, tapping, and reaming. Jigs are indispensable in the machining process. They help guide and hold workpieces to a specified location, thus ensuring that any drilling or tapping will be accurate.

What is a jig in CNC?

Jigs are devices that hold a cutting tool in place or guide its movement during repetitive operations like drilling or tapping holes. Fixtures, on the other hand, do not guide cutting tools; rather, they maintain the stability of a workpiece at a particular position, orientation, or location.

What is meant by fixtures?

Fixtures are something that is fixed or attached (as to a building) as a permanent appendage or as a structural part. a plumbing fixture. b. : a device for supporting work during machining.