A lap joint is a popular joining method that is done on wood, metal, or plastic. But a lap joint may be a full or half lap in woodworking. In a full lap, there is no material removed from either of the pieces to be joined.

In a half-lap joint, which is also called a halving joint, material is removed from both of the members in order to obtain the joint thickness of the thickest piece.

Well, in this reading, we’ll explore what a lap joint is, its applications, diagrams, types, and how to cut it. We’ll also explore its advantages and disadvantages.

Let’s begin!

Read about Softwood Plywood and Hardwood Plywood: Their Differences with this detailed guide!

What is a Lap Joint?

A lap joint, also known as an overlap joint, is a joint in which the members overlap. It can be used to join wood, plastic, or metal. One of the simplest and easiest ways to join two pieces of wood together is a lap joint, which is where one piece of wood overlaps the other.

The above carpenter, woodworker, or DIYer will fasten the boards to each other at the lap using mechanical fasteners like glue, nails and screws, or wooden pegs and dowels.

The basic lap joint itself is not particularly durable, and it is not very impressive to look at. Nevertheless, there are applications for this joint, and there are other, much stronger versions of it.

There are two types of lap joints: complete and partial. Since neither of the members that will be connected has any material removed throughout a full lap, the joint equals the sum of the two members’ thicknesses.

A half lap joint, also known as a halving joint, is created by removing material from both parts until the joint is as thick as the thickest member.

Half of each member’s thickness is removed in half-lap joints, which are usually of the same thickness.

In terms of wood joinery, this joint—which consists of two glue-jointed long-grain wood faces—is one of the strongest at withstanding shear stresses, outperforming even mortise and tenon and other well-known “strong” joints.

Application of Lap Joints

Below are the applications of lap joints:

- Lap joints are clunky-looking boards overlapping each other, used in wood framing roof construction.

- They are fast and easy to make, making them useful in assembling roof rafters.

- A collar tie is added to the lap joint to ensure the rafters are solid.

- Advanced lap joints are used in furniture making, timber construction, cabinetry, and other joinery situations.

- Temporary framing

- Tabling

- Frame assembly in cabinet making

- Used in timber frame construction, etc.

Read about 14 Types of Woodworking Joints and their Uses with this detailed guide!

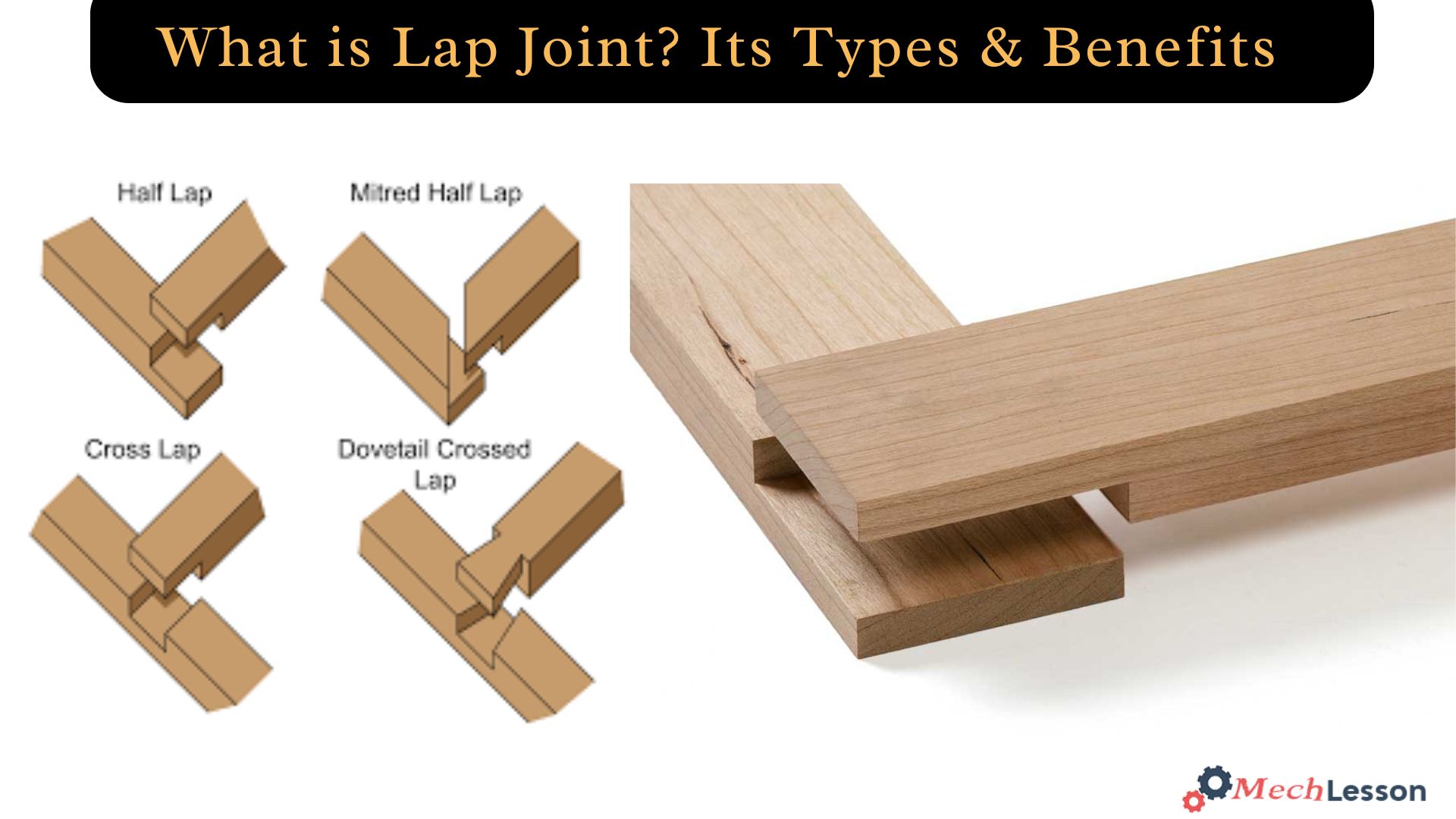

Diagram

Types of Lap Joints

Below are the various types of lap joints:

Halving Lap Joint:

The halving types of lap joints are used extensively in cabinetry for framing. It is the easiest and fastest lap joint to make, and it provides high strength through the good long grain to long grain glueing surface.

The shoulders also provide some resistance to racking. Halving lap joint may be reinforced with dowels or mechanical fasteners to avoid twisting of the wood.

Cross Lap:

The cross types of lap joints are used for internal cabinet frames and simple framing and bracing. The cross lap is much similar to the basic half lap, but the main difference between them is that the joint occurs in the middle of both pieces.

The pieces are at right angles to each other, and one member may terminate at the joint but can be extended. When one of the members terminates at the shin, which is referred to as tee lap or middle lap.

In the situation where both pieces extend beyond the joint, each of the pieces contains two shoulders and one cheek.

Read about Tongue and Groove Joints with this detailed guide!

Dovetail Lap:

The dovetail lap is used on framing applications where tension forces could pull the joint apart. The joint contains a housing that is cut at an angle to resist withdrawal of the stem from the crosspiece.

End Lap:

The end lap joint is also known as a pull lap and is also called a corner lap when the joint forms a corner; that’s in a rectangular frame. It is the basic form of the lap joint which is used to join pieces end to end, either parallel or at right angles.

The corner lap is the most common form of end lap and is used in framing. In a half-lap where the pieces are parallel, the joint is known as a half-lap splice. It is a splice joint, which an alternative to scarfing when joining shorter pieces end to end.

Well, both pieces in an end lap have one shoulder and one cheek each. This joint is used for internal cabinet frames and visible frames when the frame pieces are to be shaped.

Mitred half-lap:

The mitred half-lap joint is used for visible framing applications where a mitred corner is needed. The joint appears as one of the weakest, as the glueing surface is less.

How to Make a Lap Joint

A lap joint can be produced on two long-grain where the faces are joined with glue. Follow the steps below to make one:

The boards should be laid out on a surface. If you’re on a construction site, place both boards on the plywood decking. Position one board’s end over the other board’s end. To secure them, put a few dabs of construction glue on them and insert a screw through the lap.

Make sure the planks are angled correctly. To create the proper angle, adjust the boards. The lap joint is often used for 90-degree angles, but you will need to determine the proper angle if yours is different.

Screw through the lap with glue. To secure them together, drive a minimum of five screws or nails into the lap joint.

You will need to cut extra wood past the connection if your planks don’t create a 90-degree angle. Trim the excess wood flush with the joint’s end using a power instrument, such as a circular or reciprocating saw.

Read about What is Dovetail Joint? its Applications and Benefits with this detailed guide!

FAQs

Where are lap joints used?

Lap joints are easy to make but aren’t the sturdiest joints. These joints are often made with the help of glue or nails and are used in frames, boxes, cabinets, decks, and patio furniture, among other places.

What are the advantages and disadvantages of a lap joint?

Advantages Fairly easy to cut or route . Disadvantages Not very strong; requires glue and panel pins to increase the strength

What is the difference between a lap joint and a rabbet?

When viewed in cross-section, a rabbet is two-sided and open to the edge or end of the surface into which it is cut. In woodworking or metal fitting, a lap joint or a halving joint is a technique of joining two pieces of material together by overlapping them.

https://studentlesson.com/everything-you-need-to-know-about-lap-joints/