Regular nuts give a bolt or screw clamping force to stop axial movement, but when the application is subjected to vibration, the nuts run the risk of loosening and causing damage to the application.

This is where lock nuts come in handy because they can withstand shock and vibration. There is no one right way to use a lock nut because they vary.

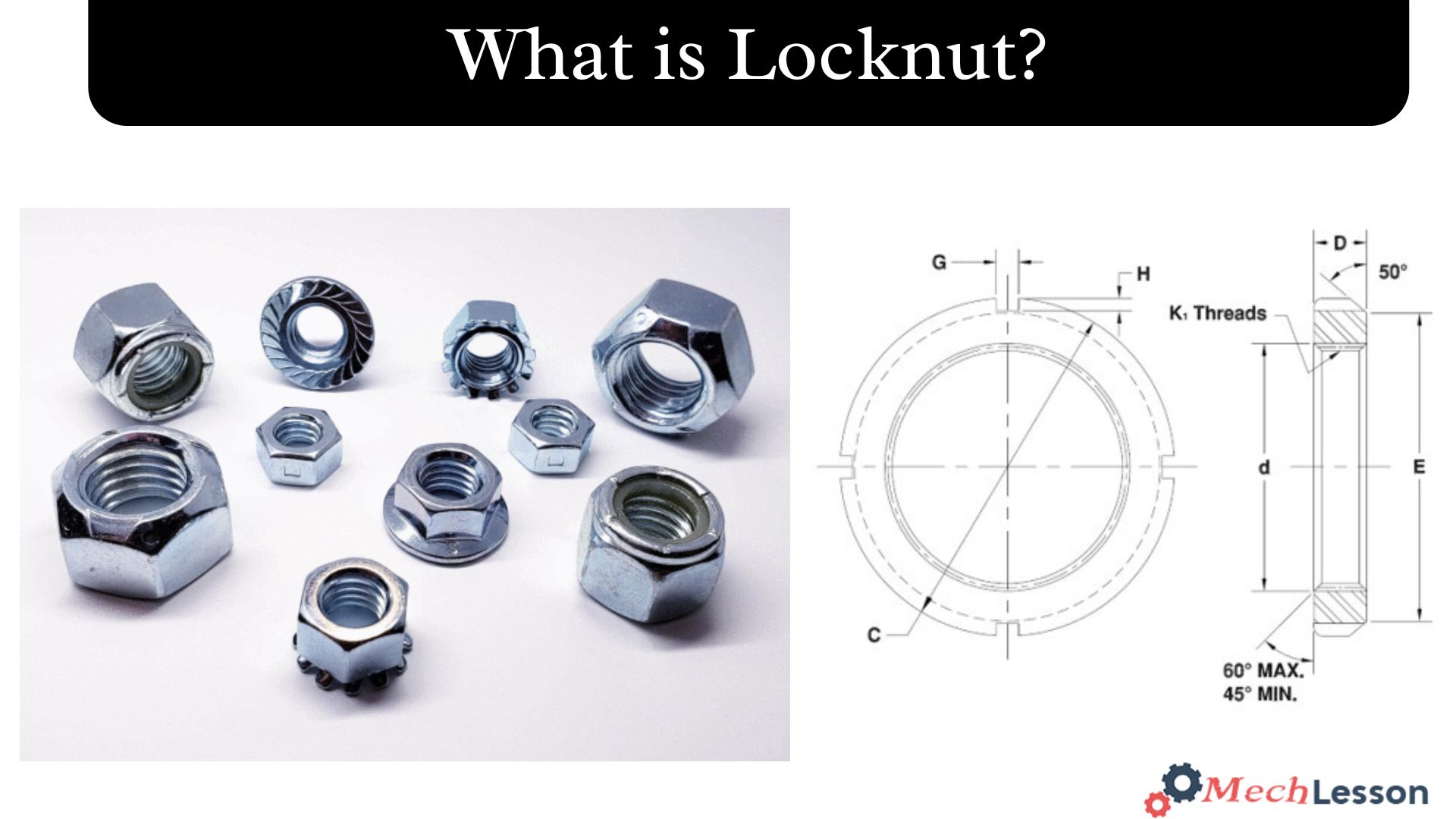

In this reading, we’ll explore what a locknut is, its diagram, types & how it works. We’ll also explore how to use it.

Let’s begin!

Read about Different Types of Bolt Heads and Their Uses with this detailed guide!

What is Locknut?

Locknuts are unique internally threaded fasteners that may be used alone or in combination with other parts to provide locking capabilities. The purpose of lock nuts is to prevent them from loosening under torque or vibration.

This type of nut is called a “Lock Nut” because it is made to be more resistant to loosening than a typical hex nut. Common uses for lock nuts include those that experience impact or vibration pressures that might eventually cause a conventional nut to loosen.

The term “lock nut,” “locking nut,” “self-locking nut,” “prevailing torque nut,” “stiff nut,” or “elastic stop nut” refers to a nut that is resistant to loosening under torque and vibration. Stiff nuts or self-locking nuts are the terms used by certain providers.

Like regular nuts, lock nuts are put into a bolt or threaded rod; however, they will not release when subjected to tension or vibration forces. Particularly, some parts of the nut bend elastically to generate a locking action. These are known as elastic stop nuts and prevailing torque nuts.

The 1930s saw the invention of lock nuts, sometimes known as stiff nuts, to reduce the expense of using nuts and washers in different kinds of machine assembly. To avoid vibration-induced nut loosening, it was formerly advisable to use two standard nuts on a single bolt. As a result, the price of nuts and washers for every bolt in the assembly doubled.

Due to the low cost of producing or purchasing individual nuts, doubling up in this manner remains a cost-effective approach at modest production levels. As a more cost-effective solution to the issue of undesired loosening, the self-locking nut was developed since it becomes exponentially more costly at scale.

Read about Screws and Bolts with this detailed guide!

Diagram

Types Of Locknut

Here are the various types of locknut including:

1. Prevailing Torque Nuts:

In order to prevent vibration loosening, a prevailing torque lock nut uses the prevailing torque concept. The force needed to drive a nut down a bolt or screwed rod’s threaded shaft so that it holds firmly and does not come loose is known as the prevailing torque in this context.

Conical lock nuts, tri-lock nuts, top locks, Stover lock nuts, and griptite nuts are a few specific types of common torque lock nuts. Many of them feature a lip or crown that is intended to be crimped around a bolt shaft after installation, and the majority are all-metal lock nuts. Enough prevailing torque is produced by this crimping procedure to keep the lock nut in place even during extreme shaking.

But not every all-metal or torque-based nut will have a crimpable part. Some, like conical flange lock nuts, are made to generate prevailing torque via various techniques. When installing or removing several of these nuts, you will need to use a wrench in both directions.

Read about Different Types of Mechanic Toolset with this detailed guide!

2. Aerotight Nuts:

All-metal (stainless steel) stiff nuts, also known as bent beam nuts, are marketed under the name Aerotight nuts. They may be used and reused several times since they contain an integrated self-locking mechanism. They are made to stay in place regardless of how tightened they are, and they don’t need any more parts.

3. Knurled Nuts:

Better finger grip is provided by knurled nuts, which have a knurling pattern around the outer edge. A knurled nut is a kind of locking nut that may be manually tightened and loosened, similar to thumb nuts and insertion nuts. That is to say, it is a hand nut rather than a nut that is intended to be wrenched into position. Nonetheless, certain versions come with head slots for screwdriver drives.

They are less frequently used in applications where the nut needs to be turned very firmly against a threaded rod or bolt since they are primarily meant for hand tightening. They come in useful when a locking nut needs to be taken out and put back in on a frequent basis or when you want to eliminate the possibility of stripping or overtightening.

3. Nylon Insert Lock Nuts:

These are a popular and widely used type of locking nut because they are inexpensive to buy and work well in a variety of settings. They have an inner sleeve made of nylon plastic that is designed to deform around the bolt threads and create binding friction.

This makes it harder to reuse the nut more than once, but it is a useful design for securely joining softer materials like wood and plastic without the risk of overtightening and damaging the material’s surface.

They are also useful for resisting vibration loosening, and they are frequently used for applications such as automotive repair and household appliances. The nut itself is typically made of stainless steel, zinc, or brass.

4. Wedge Lock Fasteners:

The wedge-lock nut is a combination of the nut and a wedge-lock washer, which has a cam with a rise larger than the bolt’s thread pitch. These fasteners are single-piece and are frequently delivered pre-assembled. They work well in difficult situations (such as under vibration and severe loads) and may be used repeatedly on bolted joints.

5. Spring Locknut Washer:

One of the washer’s edges digs into the item below when the nut tightens the washer against it, increasing the resistance and making it harder for the nut to loosen. Many types of spring lock washers are produced, some of which work pretty well. By drilling and pinning or by using a thread locker, a standard nut may likewise be made into a locknut.

How does Locknut Work?

When fastened to the shaft of a bolt or screwed rod, lock nuts function similarly to other threaded fasteners and fixes. The main distinction is that locking nuts are made and machined such that, once screwed on, they won’t readily back off, or work themselves loose.

Because of this, lock nuts are particularly helpful in situations where torque or vibration forces will be applied to the bolt or nut assembly during installation. Engines and other automobile components are a clear illustration of this. Numerous other mechanical and industrial applications also make extensive use of them.

The majority of locking nuts function in one of two ways. Some are made with threading patterns that include pitted or flanged grooves to improve friction once attached. Others have a positive locking mechanism or device incorporated into the design; metal locking nuts, for instance, include a tiny metal lip or crown that, when inserted, may be pinched inward.

This will stop the nut from loosening during vibration and physically secure it to the bolt shaft. There are several subtypes of lock nuts within these two primary groups. Below, we will go into further detail about a few of the most well-liked types of these.

Read about Car Door Drain Holes: Where is it Located? with this detailed guide!

How to Use Locknut

Depending on the specific type of locking nut you are using, the solution to the issue of how to lock nuts on bolts varies somewhat. The initial threading and finger-tightening, however, mostly function exactly as they would with a conventional hex nut. Usually, you would next need to use a wrench or other similar equipment to tighten the lock nut even further until you got the desired grip.

Because some friction or torque-based designs require that a nut only lock correctly when secured in one way, it might be easy to determine which end of a lock nut goes on first. You must be mindful of whether you are using a locknut that is threaded clockwise or counterclockwise, though.

It might be required to utilize a lock nut washer in addition to the nut itself for various locking nut designs and brands in order to obtain the full lock.

FAQs

Where is Locknut used?

Lock nuts are also frequently used to secure gears, belt pulleys, and other machine components. Lock nuts have to be secured to prevent unintentional loosening by: A locking device that engages a keyway in the shaft or key slot in the adapter sleeve or a locking mechanism integrated in the nut.

Can you unscrew a lock nut?

How to Get Locking Wheel Nuts Off. Place a socket that is one size smaller than the lug nut, and place the socket on the nut’s head. Tap the socket onto the nut with a mallet or hammer. Then, use a breaker bar to twist the lug nut and remove it.

What is the difference between a lock nut and a nyloc nut?

A Nyloc nut is a locking nut that has a nylon insert at the end which is slightly smaller than the diameter of the screw. The nylon insert deforms over the thread of the screw, creating friction which locks the nut in place. The side of the nut without the nylon ring is threaded onto the bolt first.

What is another name for a lock nut?

A locknut, also known as a lock nut, locking nut, self-locking nut, prevailing torque nut, stiff nut or elastic stop nut, is a nut that resists loosening under vibrations and torque.