Mortise and tenon joints have been in existence for thousands of years to join pieces of wood together, mainly when adjoining pieces that meet at right angles.

The basic type consists of a mortise hole and a tenon tongue, though there are many variations of the type of joint. mortise and tenon joints are simple and strong.

The tenon which is formed at the end to lock the joint in place may be glued, pinned, or wedged. Well, in this reading, we’ll explore what mortise and tenon joints are, their applications, diagrams, types, and how to make them. We’ll also explore their advantages and disadvantages.

Let’s begin!

Read about 14 Types of Woodworking Joints and their Uses with this detailed guide!

What are Mortise and Tenon Joints?

A mortise and tenon joint is a woodworking joint where a tongue (the tenon) is inserted into a corresponding hole (the mortise) to create a strong, stable connection, typically at a 90-degree angle.

Mortise precisely cut the opening or recess in one piece of wood. A tenon is a protruding tongue, usually cut at the end of another piece of wood, designed to fit snugly into the mortise.

Mortise and tenon joints are strong and reliable joints that work well for a variety of tasks. They attach to one another by friction fitting or glueing.

An appealing appearance is also provided by the mortise and tenon joint. The difficulty of creating this junction due to the need for exact measurements and accurate cutting is one of its disadvantages. A mortise and tenon joint is simple and robust in its most basic configuration.

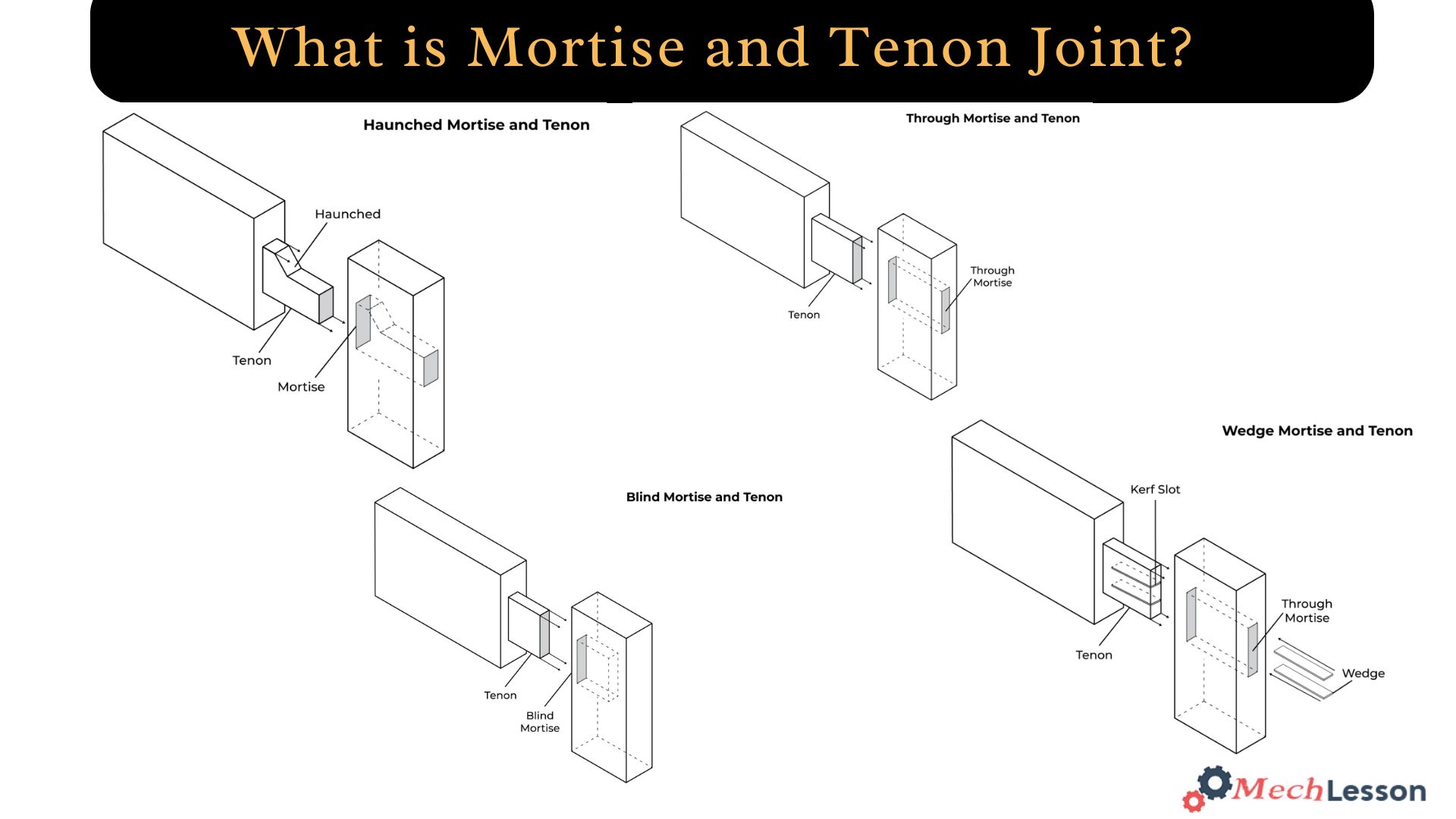

The common types of these joints are blind mortise and tenon; the tenon doesn’t extend through the mortise, creating a flush joint. Through mortise and tenon are also common, where the tenon extends through the mortise, often with a pin or wedge for added strength.

Applications

Apart from woodworking, the mortise and tenon joint is also used in other fields like blacksmithing and stonemasonry. This joint has been widely used on wood components such as beams, roof frames, structures and brackets.

The mortise and tenon joint (interlock) performed on them was made to perfectly fit without using any mechanical fasteners or glues. This enables the wood to expand and contract due to humidity. This joint is also an old method of constructing a wooden lining of water wells.

Mortise and tenon joints are used to join two pieces of wood at a 90-degree angle, creating a strong and durable joint. They are ideal for furniture making, cabinet making, and other woodworking applications.

Read about Lap Joint with this detailed guide!

Diagram

Types of Mortises and Tenon Joints

Mortises

A mortise is a cavity cut into a timber piece in order to receive a tenon. Below are the various types of mortises and tenons performed in woodworking:

- Open mortise: this type of mortise has only three sides.

- Stub mortise: it is a shallow mortise; its depth is determined by the size of the timber, and the mortise does not go through the workpiece.

- Through mortise: this mortise passes entirely through a piece

- Wedged half-dovetail: in this mortise, the back is wider, or taller, than the front. The space for the wedge initially creates space for the insertion of the tenon. The wedge prevents the withdrawal of the tenon after being engaged.

- Through-wedged half-dovetail: in this mortise type, it passes entirely through the piece.

Tenons

Tenon is a projection on the end of a timber piece which is designed to fit in a mortise when inserted. It is usually wide but taller than the wideness. Below are the various types of tenons cut by the woodworker:

- Stub tenon: the depth depends on the size of the timber piece, and the tenon is shorter than the width of the mortise piece, so it does not show.

- Through tenon: the through types of tenon pass entirely through the piece of wood it is inserted into. It will be clearly visible at the backside.

- Loose tenon: the tenon is a separate part of the joint which is opposed to a fixed tenon that is an integral part of one of the pieces to be joined.

- Biscuit tenon: the tenon is like a thin oval piece of wood, shaped like a biscuit

- Pegged or (Pinned) tenon: in this type of tenon, a peg or dowel pin is driven in through one or more holes drilled through the mortise side wall and tenon. This helps to strengthen the joint. it common in timber framing joints.

How to Make a Mortise and Tenon Joint

The mortise is typically cut into the piece that will receive the tenon. The tenon is cut on the end of the other piece, ensuring a snug fit. The pieces are then glued together, with the tenon inserted into the mortise.

A mortise and tenon joint is a mechanical connection between two pieces of wood that resists pulling and twisting forces. It works by inserting a tenon into the mortise, creating a strong mechanical connection.

The strength of the joint is attributed to the large surface area between the tenon and the mortise, the mechanical interlock between the tenon and the mortise, and the end grain-to-long grain connection.

Historically, these joints were left unglued, but in modern fine woodworking, most are glued for maximum strength and durability.

The video below shows how to cut mortise and tenon joints:

Advantages and Disadvantages of Mortise and Tenon Joints

Advantages:

- Strength and durability due to extensive wood-to-wood contact and mechanical interlock.

- Aesthetics: Nearly invisible, indicating high-quality craftsmanship.

- Versatility: Adaptable to various wood types, project sizes, and design styles.

- Longevity: Well-made joints can last for centuries, as seen in surviving antique furniture and timber-frame buildings.

- Repairability: Unlike modern joinery methods, mortise and tenon joints can often be repaired if they loosen or fail.

Disadvantages:

- Precision and skill required: Requires accurate measurement and layout, skilled use of tools, and understanding of wood properties.

- Time-consuming process: labour-intensive, requiring multiple steps.

- Tool investment: Requires specialised tools for efficiency.

- Material limitations: Works best in solid wood, less suitable for plywood, engineered woods, thin stock, and end-grain to end-grain connections.

Related: What is Dovetail Joint? its Applications and Benefits

FAQs

What is a mortise and tenon joint?

A mortise and tenon joint is used most often to join two pieces of wood at 90 degrees, and consists of two parts; the mortise hole and the tenon tongue. On the surface it seems like a very simple join but is one of the strongest there is, and subsequently has been used by cabinetmakers and joiners for generations.

What are the four types of mortise and tenon?

Plain or simple: shoulders on two sides.

Blind: shoulders on three or four sides.

Through: tenon projects through, sometimes pinned,

Keyed: tenon projects through and has wedged shaped key to hold joint tight.

Wedged: where tenon has some form of wedge driven to hold.

What is the rule of thumb for mortise and tenons?

The point is, these rules are just a guideline. Tenon thickness: A tenon’s thickness should be one-third the thickness of the stock being mortised. So, if you are joining two pieces of 3/4″material, the tenon should be ¼” thick (1/3 of ¾).

Which side gets cut first the mortise or the tenon?

Start with the mortise. Always cut the mortise first and then size the tenon to fit snugly. It’s quicker and easier to adjust the dimensions of a tenon (as we’ll show later) than to change a mortise.