A reciprocating pump is a type of positive displacement pump that works on the principle of forward and backward movement of a piston. Unlike a centrifugal pump, which uses the kinetic energy of the impeller to supply the fluid.

These reciprocating pumps can last for decades if properly maintained. Reciprocating pumps are often used where a relatively small quantity of liquid is to be pumped and where the delivery pressure is quite large.

Well, in this reading, we’ll explore what a reciprocating pump is, its applications, functions, parts, diagrams, classifications, types, and how it works. We’ll also explore its advantages and disadvantages.

Let’s get started!

Learn about pump with this detailed guide!

What is a Reciprocating Pump?

Just as stated in the introduction, a reciprocating pump is a class of positive-displacement machines typically used for low-flow, high-pressure operations. Reciprocating pumps have a stationary chamber that traps liquid with a piston or plunger.

This type of positive-displacement pump includes piston pumps, plunger pumps, and diaphragm pumps.

The Hydraulic Institute and ANSI categorize reciprocating pumps into four types, which were mentioned above. Both pistons and diaphragms are used to provide pumping action, and valves are used to regulate flow in and out of the pump body.

These pumps are available in various sizes ranging from large-scale power pumps to smaller pressure-washer units.

Applications of Reciprocating Pump

Below are the various applications of reciprocating pumps:

- Oil refineries

- Vehicle water servicing centers

- Gas industries

- Petrochemical industries

They are used for the following purposes:

- Vessel, pipe, tank, tube, condensate pipe, heat exchanger, etc. cleaning,

- Oil drilling, refineries, production, disposal, and injections.

- Pneumatic pressure applications.

- Vehicle cleaning.

- Sewer line cleaning.

- Wet sandblasting

- Boiler feeding

- High-pressure pumps for the RO system (Reverse osmosis)

- Hydro testing of tanks, vessels, etc.

- Firefighting system.

- Wastewater treatment system.

You should also learn about Centrifugal Pump with this detailed guide!

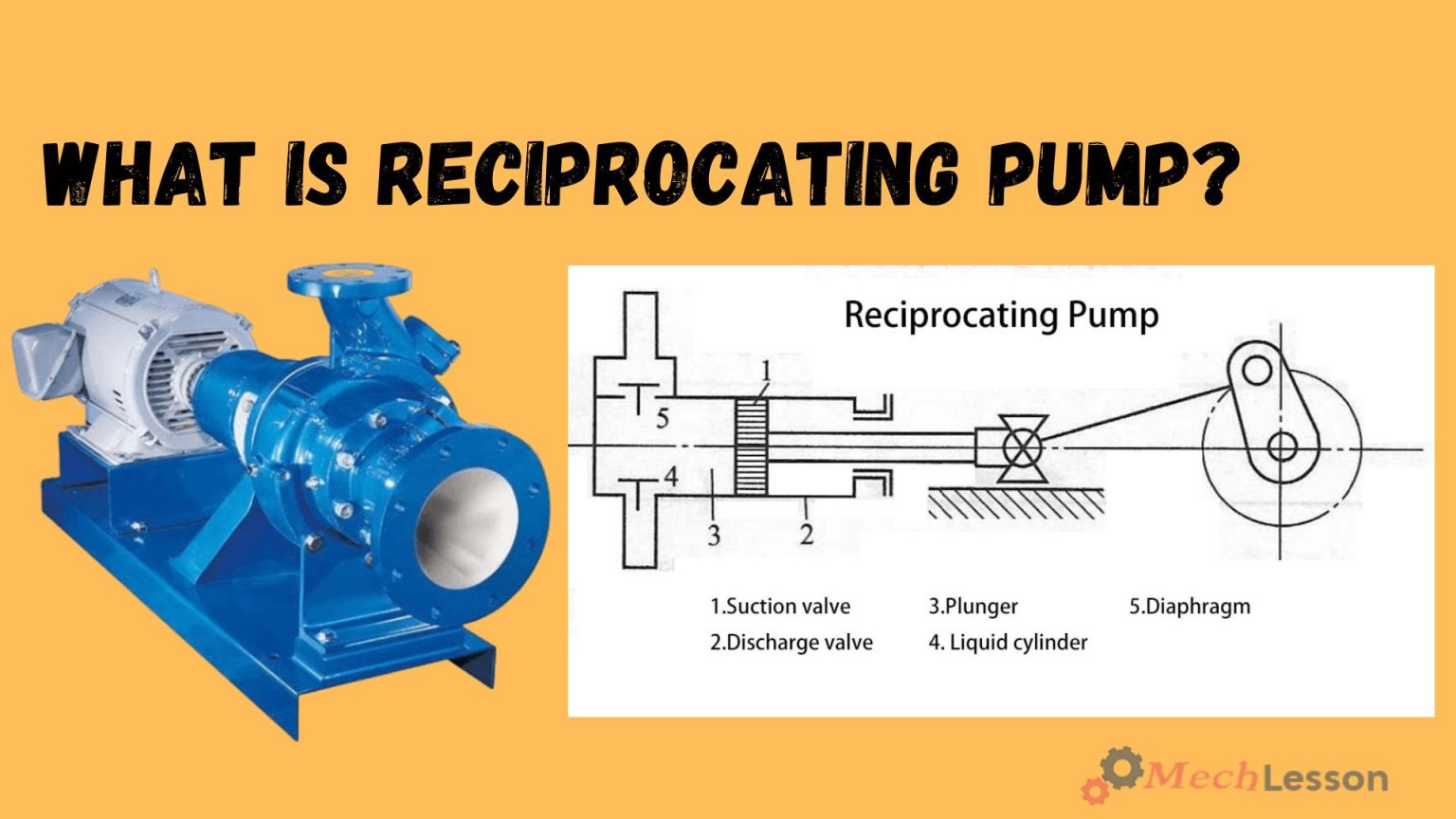

Components of Reciprocating Pump

Below are the main components of the reciprocating pump and their function:

- Strainer – removes all impurities from the fluid before entering the pump. It is mounted on the suction pipe.

- Suction pipe – this is what sucks fluid from the reservoir.

- Suction valve – it is a non-return valve, also installed on the suction pipe. It helps the flow of fluid from the reservoir to the pump.

- Cylinder or liquid cylinder – this is where pressure increases. It is a hollow cylinder with coatings, it contains a piston, and it rings.

- Piston or plunger and piston rod – the piston is directly connected to a rod, making it a piston rod. The piston rod is further connected to the connecting rod. This is what causes the reciprocating motion inside the cylinder.

- Piston rings – this is another vital component in a reciprocating pump, as it protects the piston surface. It also protects the cylinder’s inner surface from wear and tear, making the system operate smoothly.

- Packing – packing is required in this pump in order to have proper sealing between the cylinder and piston. It helps to stop leakage.

- Crank and connecting rod – the crankshaft is connected to a power source. The connecting rod connects the crank and piston rod. All these work together for the attainment of the reciprocating motion.

- Delivery valve (non-return type) – the delivery valve helps to build up the pressure just as a suction valve does. It protects the pump from backflow.

- Delivery pipe – this part of a reciprocating pump helps to supply the fluid to its destination.

- Air vessel – only a few types of reciprocating pumps have an air vessel. It helps to reduce the frictional head or acceleration head.

Diagram

You should also learn about Piston Pump with this detailed guide!

Classifications of Reciprocating Pump

Reciprocating pumps are classified depending on the following:

Source of Work

- Simple hand-operated reciprocating pump.

- Power-operated deep well reciprocating pump

Mechanism

- Single-acting reciprocating pump

- Double-acting reciprocating pump

- Triple-acting reciprocating pump

Numbers of Cylinders

- Single cylinder, consisting of a single cylinder connected to a shaft.

- Double cylinder – consisting of two cylinders connected to a shaft.

- Triple cylinder – consists of three cylinders connected to a shaft.

Types of Reciprocating Pump

Below are the various types of reciprocating pumps and their functions:

Piston Power Pump

These types of reciprocating pumps are classified by their orientation (vertical or horizontal), action (single or double), pump element (piston or plunger), and number of stages (simplex, duplex, or triplex). This power pump can be used with power and pressure washers. They can deliver high-pressure water at low volumes.

Piston power pumps are usually available as duplex or triplex units. Single-acting pumps pressurize only in one direction of the stroke, while double-acting pumps pressurize in both directions.

Piston types of power pumps are used on a much larger scale. Petrochemical industries use it for hydraulic fracking, saltwater disposal, etc. It is also used for pumping sand-laden fluids and slurries.

Steam Power Pump

Steam types of reciprocating pumps do not convert rotary motion to linear motion by directly using a steam-driven piston to the piston of the power pump. The pumps are generally double-acting on both the steam end and the fluid end. There is a lever connected to the piston rod that switches steam flow as the steam.

This occurs as the steam and pump pistons closely reach the end of their stroke. Two steam cylinders are commonly used. With the API 674 standard, steam power pumps are used in hazardous locations by oil, petrochemical, and refining industries.

You should also learn about Submersible Pump with this detailed guide!

Metering Pump

With these types of pumps, the means of dispensing chemicals, pastes, etc. became much easier and more effective. This is achieved using a reciprocating piston or plunger. The diaphragm method can also be used in metering pumps. Especially in industrial processes and food and pharmaceutical applications.

These methods of pumping usually have adjustable stroke lengths so that dosage levels can be set. The metering pumps are available in many different embodiments, including larger ones for chemical injection in process plants. The very small designs are used for pharmaceutical filling, adhesive dispensing, etc.

Diaphragm Pump

These types of pumps use flexible membranes that hide the pump cavities. It is either air-operated or electric. Diaphragm pumps are useful for transferring oils and similar hazardous fluids.

It also ranges in size from industrial units used in permanent installations to small portable contractor pumps used for site jobs. Several methods are used to actuate this pump: mechanical linkages, hydraulic fluid, air, etc.

How Does a Reciprocating Pump Work?

The working of reciprocating pumps is quite simple and can be easily understood. Power is supplied to the pump system, which allows the crank to rotate through an electric motor. There is an angle made by the crank so that the movement of the piston inside the cylinder can be achieved.

Using the diagram above, the piston moves towards the extreme left of the cylinder when the crank meets position A. Conversely, the piston moves towards the extreme right of the cylinder when the crank meets position C.

When the piston is towards the right extreme position, a partial vacuum in the cylinder takes place. This makes the liquid enter into the suction pipe. Well, this occurs due to atmospheric pressure on the sump liquid, which is much less than the pressure inside the cylinder.

The water enters into the cylinder through a non-return valve due to the difference in pressure. The water that stays in the volume of the cylinder is then sent into the discharge pipe. It is achieved through a discharge valve, and it is done when the crank rotates from C to A. This is when the piston moves in a forward direction.

Because of the forward direction movement of the piston, the pressure increases inside the cylinder. The pressure is greater than the atmospheric pressure. This causes the delivery valve to open and the suction pipe to close.

However, once the water enters the delivery valve, it cannot return back to the cylinder. It is because a unidirectional valve or non-return valve is used. At this point, the water enters the delivery pipe so that it can be sent to its destination.

Learn about Screw Pump with this guide!

Advantages and Disadvantages of Reciprocating Pump

Advantages:

Below are the benefits of a reciprocating pump in its various applications:

- Liquid can be delivered at high pressure from the sump to any desired height.

- Priming is not required as a centrifugal pump.

- The continuous rate of discharge is allowed in the reciprocating pump.

Disadvantages:

Despite the good advantages of reciprocating pumps, some limitations still occur. Below are the disadvantages of a reciprocating pump in its various applications:

- Maintenance cost is high due to a large number of moving parts.

- The initial cost of the system is also high.

- Viscous fluids are difficult to pump. Finally,

- Lesser flow rate.

You should also learn about Gear Pump with this detailed guide!

Conclusion

A reciprocating pump is a positive displacement pump that uses a piston or plunger to move fluid through a system by reciprocating motion. It is highly effective for high-pressure, low-flow applications and is commonly used in industries like oil and gas, chemical processing, and water treatment.

While it requires more maintenance than other types of pumps due to its many moving parts, its precision and pressure capabilities make it indispensable in specific tasks.

FAQs on Reciprocating Pumps

What is a reciprocating pump?

It’s a type of positive displacement pump where a piston or plunger moves back and forth to draw in and push out fluid.

What are the main types of reciprocating pumps?

- Single-acting reciprocating pump

- Double-acting reciprocating pump

- Diaphragm pump (a variation that uses a flexible diaphragm instead of a piston)

What are the main components of a reciprocating pump?

- Cylinder

- Piston or plunger

- Crankshaft

- Suction and delivery valves

- Connecting rod

Where are reciprocating pumps commonly used?

- Oil and gas industry

- Chemical plants

- High-pressure cleaning systems

- Hydraulic systems

What are the advantages of reciprocating pumps?

- High pressure output

- Accurate fluid handling

- Suitable for viscous or sludgy fluids

- Self-priming capability

What are the disadvantages?

- Low flow rate compared to centrifugal pumps

- Higher maintenance

- Pulsating flow may require dampers

Are reciprocating pumps energy-efficient?

They are efficient in high-pressure applications but may not be the best choice for large-volume, low-pressure systems due to mechanical complexity.