Submerged arc welding SAW is a welding technique that involves the formation of an arc between a continuously fed electrode and the workpiece to be joined. The SAW process creates a flux in the form of a blanket of powder that surrounds and covers the arc, serving as a shield to the weld. We also use this to add alloying elements to the weld pool.

The SAW welding techniques offer an extremely high metal deposition rate, high weld accuracy, fusion quality, a low rate of weld discontinuities, and depth of penetration. MIG and Flux-cored welding offer similar qualities, but they can’t match the deposition rate of submerged arc welding.

The difference between SAW and SMAW is that the SAW process uses an external flux that is delivered at the arcing area to protect or act as a shield to the weld. On the other hand, the flux-coated electrode used in SMAW helps to shield the welding process from any atmospheric interaction.

Well, in this reading, we’ll explore what SAW is, its applications, parts, equipment, diagram, and how it works. We’ll also explore the advantages and disadvantages of submerged arc welding.

Let’s Get Started!

Related: What is Welding Bead, Its Functions and Types?

What is Submerged Arc Welding (SAW)?

Submerged arc welding is another type of arc welding process that uses a continuously fed consumable tubular electrode. It can be operated in the automatic or mechanized mode. It can also be operated on semi-automatic (hand-held) SAW guns with the delivery of pressurized or gravity-flux-fed.

This process is not suitable for flat or horizontal filler welding positions; the horizontal position has been done with a special arrangement in order to support the flux.

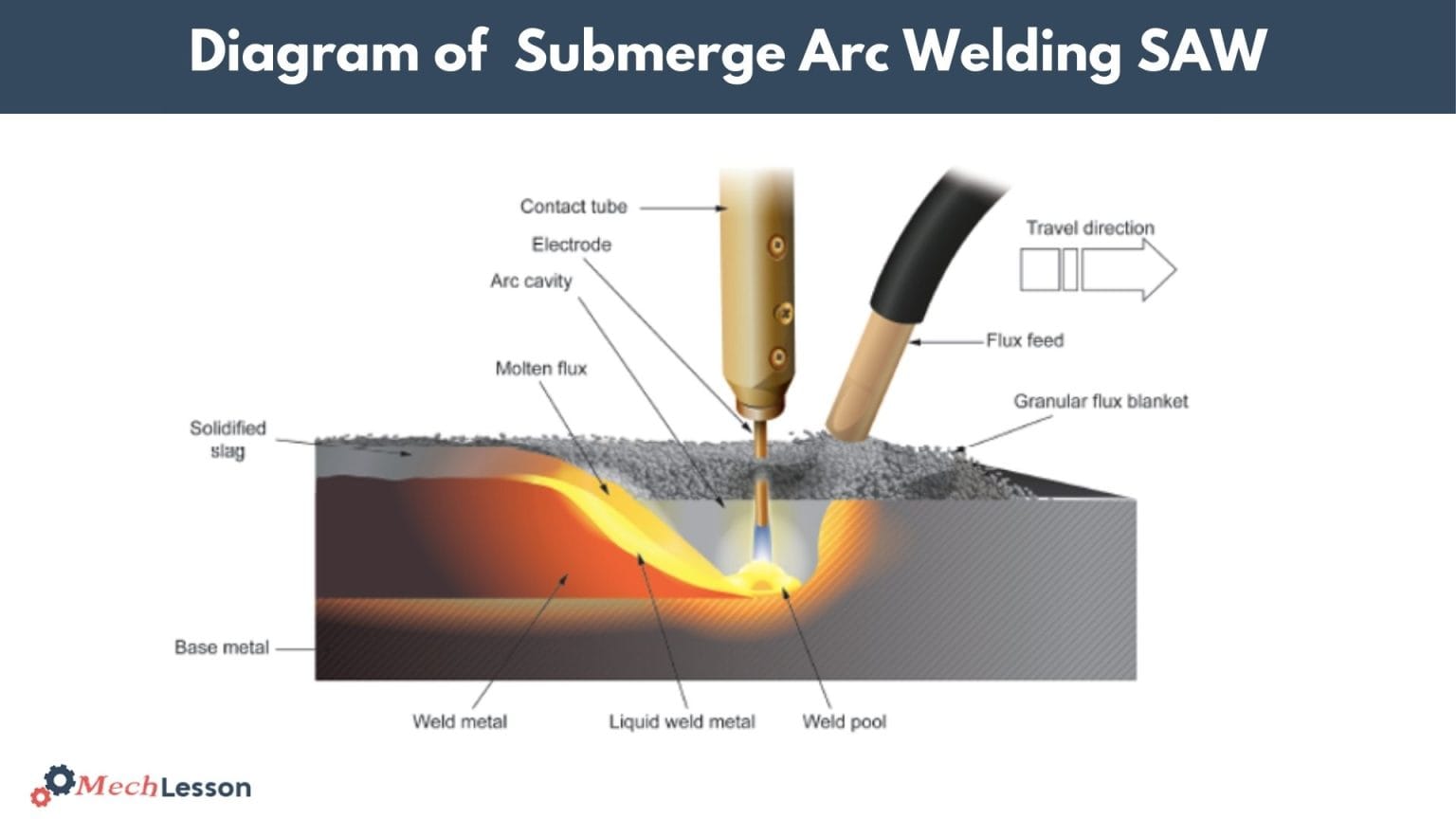

In this welding process, the area where the arc forms and the liquid metal are shielded from outside air pollution by a layer of granular flux made up of lime, silicon, manganese oxide, calcium fluoride, and other materials.

The molten flux becomes conductive and creates a current between the electrodes and the base metal. The thick flux layer covers the metal completely, preventing sparks and spatters and supporting the intense ultraviolet radiation and fumes that are part of the welding process.

SAW was the first patent in the year 1935 and covered an electric arc beneath a bed of granulated flux. It was originally developed by Jones, Kennedy, and Rothermund.

Applications of SAW

The Submerged Arc Welding (SAW) process is a versatile welding method suitable for various industries, including structural and vessel construction, low alloy steels, stainless steels, nickel-based alloys, and surfacing applications. It is particularly suitable for welding pressure vessels like boilers, achieving a smooth weld pool from the continuously fed electrode.

Shipbuilding also benefits from SAW’s ability to create long, straight welds for heavy metals in ship parts, both indoors and outdoors. It is also suitable for automotive and military industries due to its speed and efficiency, offering the option to have multiple or single-pass welds based on the metal’s thickness.

Lastly, the SAW process allows deep weld penetration, making it attractive for the railway industry. SAW is an all-around effective and adaptable welding technique with a wide range of uses across industries.

Related: How Does ElectroSlag Welding (ESW) Works?

Parts and Equipment of SAW

SMAW is a submerged arc welding process that utilizes a welding head, flux hopper, and electrode to create a weld. The welding head supplies filler and flux metal to the welding joint, while the flux hopper stores and controls flux deposition. The granulated flux protects the weld from atmospheric contamination, cleans the metal, and modifies its chemical contamination.

The electrode, typically 1.6mm to 6mm thick, feeds the filler material to the welding joint. This process is a significant advancement in arc welding technology. Well, let’s further explore the parts and equipment.

Wire Electrode:

A wire electrode is a crucial component in welding systems, feeding the wire into the weld. Various power sources can operate the wire electrode, which is typically between 1.6mm and 6mm thick and can be solid, twisted, or cored.

You might need different types of wire electrodes and systems to get the right weld shape, like using two wires, several wires, one wire with hot or cold additions, metal powder, or tubular wire. We use additional wires to enhance the weld pool’s deposition.

Flux:

Flux is a crucial component in various applications, including bonded flux, molten flux, and granular flux. Granular flux, composed of oxides like aluminum, calcium, magnesium, manganese, silicon, titanium, and zirconium, is suitable for electrodes due to its chemical reaction.

Bonded flux, produced by drying and baking the composition, can contain alloying elements and offer flexibility and protection against rust. Fused flux, produced by melting the composition in an electric furnace, forms homogenous particles, making it ideal for consistent welds along the bead.

Power Source:

Submerged arc welding (SAW) utilizes multiple electrode systems to manipulate weld results. These systems enable the operation of wires at varying power sources, thereby enhancing control over the bead profile and penetration. There are products that offer stability and penetration and also increase deposition rates. AC is the middle ground, achieving a balance between these two.

Related: MIG vs Stick Welding: Choosing the Best Method for Your Needs

Diagram of Submerged Arc Welding (SAW)

How Does Submerged Arc Welding (SAW) Work?

Submerged-arc welding (SAW) is a versatile arc welding process that creates an arc between a continuously fed electrode and the workpiece. A powdered flux blanket generates a protective gas shield and slag, protecting the weld zone. The electrode can be a solid or cored wire or a strip made from sintered material.

Constituents can fuse to form a glassy slag, or they can agglomerate using a binder and corning process to form the flux. The chemical nature and size distribution of the flux help determine the arc’s stability, the mechanical properties of the weld metal, and the shape of the bead.

SAW is typically operated as a mechanized process, with factors such as welding current, arc voltage, and travel speed affecting bead shape, depth of penetration, and chemical composition. The operator relies heavily on the parameter setting and positioning of the filler wire.

Variants of SAW include using two or more wires, adding chopped wire to the joint, and using metal powder additions. Feeding a small-diameter, non-conducting wire into the leading edge of the weld pool can increase deposition rates by up to 20%.

Related: How Does Flux-Cored Arc Welding (FCAW) Works?

Advantages and Disadvantages of Submerged Arc Welding

Submerged arc welding (SAW) offers numerous advantages, such as strong, sound welds; minimal welding fume and arc light; suitability for both indoor and outdoor work; less distortion; deep weld penetration; minimal edge preparation; high deposition rates; and the ability to weld thick materials.

However, it has some disadvantages, such as its limited use in flat or horizontal welding positions, limited use for ferrous metals like steel and stainless steel, and its limitations in long straight seams or rotated pipes and vessels.

Additionally, it only works with high-thickness materials and requires backing strips for proper penetration. Despite these disadvantages, SAW offers advantages such as automation, less smoke, edge training, and no chance for oxide sparks due to its submerged nature.

However, it also has disadvantages such as incomplete processes for certain metals, tedious flux usage, potential health issues due to flux, and the need for slag removal after welding.

Related: What is Welding Spatter? Its Causes & How to Prevent It