A two-stroke engine, which is known as a two-cycle engine, is a type of internal combustion engine that takes two strokes to complete a power cycle.

These engines are lightweight, weighing up to 50% less, and provide more torque at higher RPMs when compared with four-stroke engines.

In this reading, we’ll explore what a two-stroke engine is, including its diagram, parts, and how it works. We’ll also explore its advantages and disadvantages.

Let’s begin!

Related: What Is A Four-stroke Engine? Its Diagram, Stroke Cycle, and Working

What Is A Two-Stroke Engine?

A two-stroke engine is a type of small internal combustion engine that uses two different piston strokes to complete one operating cycle. During this cycle, the crankshaft rotates once, and the piston goes up and down once to ignite the spark plug.

This means it only takes one piston stroke to complete the combustion cycle. When the compression stroke occurs, compressed fuel explodes, and the incoming fuel forces the exhaust out of the cylinder.

The spark plugs fire on each revolution. Engine power is produced every two piston strokes.

Parts of Two-stroke Engine

- Crankshaft: It converts piston reciprocation into rotational motion that drives driving gears.

- Piston: The forces produced by the combustion of the gases propel the piston. The piston converts this chemical energy into mechanical energy that the crankshaft uses.

- Connecting Rod: This connects the crankshaft and piston head.

- Inlet Port: Fuel and air enter the piston chamber through it.

- Spark Plug: This is the component inside the piston chamber that ignites the fuel-air mixture.

- Exhaust Port: During the downstroke, this hole lets out exhaust gases.

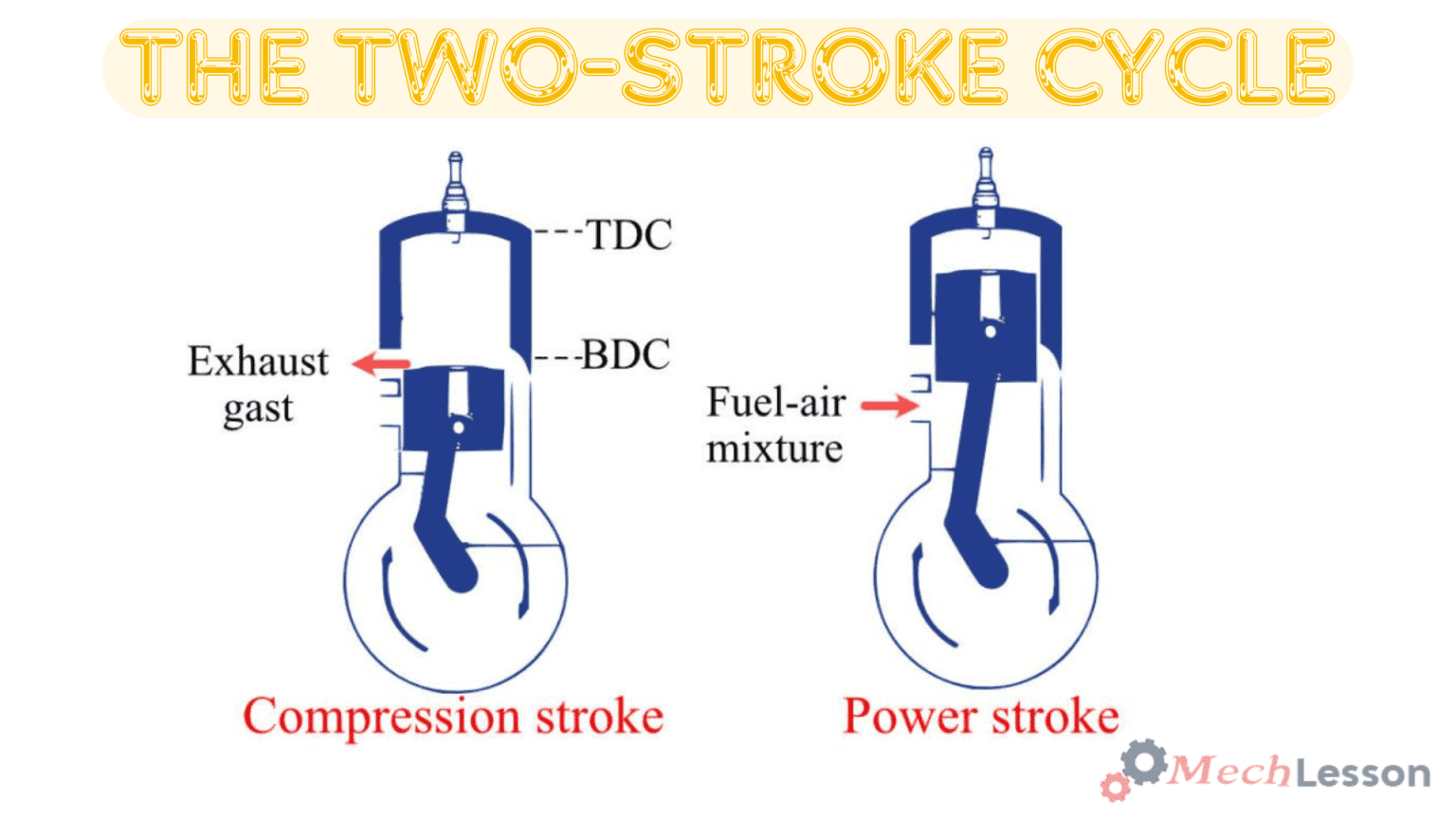

Diagram of Two-Stroke Engine

Related: Difference between SI (Spark ignition) and CI (Compression ignition) engines

How Two-Stroke Engines Work?

A two-stroke engine needs just one upstroke and one downstroke of the piston to complete a power cycle, unlike a four-stroke engine, which requires four strokes (intake, compression, power, and exhaust). Here’s a breakdown of how it works:

1. First Stroke (Suction and Compression)

In this stroke cycle, the piston moves from the bottom center to the top center, while all three ports (inlet, transfer, and exhaust) are closed. The fuel on top of the piston is compressed, and the spark plug ignites the charge to create a power stroke.

The connecting rod then transfers this power to the crankshaft. A partial vacuum created in the crankcase is used to open the inlet port, which allows the fuel-air mixture inside.

2. Second Stroke (Power and Exhaust Stroke)

In the second stroke cycle, the piston moves down from the top center, and the inlet port is closed. The piston’s downward movement pushes the fuel-air mixture, while the transfer port introduces the charge from the crankcase.

At this point, the exhaust port is open and most of the exhaust gas leaves the cylinder. The pressure of the fuel-air mixture flowing downward pushes the remaining exhaust gas through the exhaust port. The fresh charge then pushed out the exhaust gas.

The 2-stroke petrol engine works this way, and the 2-stroke diesel engine works similarly, except it has a fuel injector instead of a spark plug. Here’s how two-stroke petrol and diesel engines work.

Related: What Is A Petrol Engine, Its Application, Parts and How it Works?

Two-Stroke Petrol Engine

We recognize small petrol two-stroke engines as crankcase-compression engines. In a total-loss system, a petrol mixture lubricates them. The oil is mixed at a preceding time with the gasoline in a ratio of about 1:50.

The oil forms emissions as oily droplets in the exhaust or by being seared. This helps to produce extra exhaust emissions with extreme hydrocarbons than four-stroke engines of equal power output.

Some two-stroke engine designs allow for equal opening times for the intake and exhaust ports. The exhaust stream allows some amount of unburned fuel gases to exit. However, small air-cooled engines with high combustion temperatures may give high NOx emissions.

Two-Stroke Diesel Engine

Two-stroke diesel engines entirely depend on the heat of compression to ignite. A uniflow diesel engine receives air to the chamber, and the exhaust gases leave through an overhead poppet valve.

In the case of Schnuerle-ported and loop-scavenged engines, intake and exhaust take place through piston-controlled ports. Forced induction is a scavenging technique for all two-stroke diesel engines.

Though some designs use a mechanically driven roots blower, marine diesel normally uses exhaust-driven turbochargers and electrically driven auxiliary blowers for low-speed operation when turbochargers are unable to deliver enough air.

A marine two-stroke diesel engine directly fits a propeller, enabling it to run in both directions. The valve timing and fuel injection are mechanically readjusted by using a different set of cams on the camshaft.

Related: What Is Diesel Engine? Its Diagram, Applications and Parts

Modern Two-Stroke Engine

Modern two-stroke engines are designed with a power valve system. Manual fitting occurs in or around the exhaust ports. These valves work as follows:

Closing off the top part of the exhaust port transforms it, changing the timing. Or by altering the quantity of exhaust, which changes the vibrant frequency of the expansion chamber.

One of the greatest advantages of two-stroke engines is direct injection. It helps in abolishing some pollution and waste produced by the carbureted two-stroke; the amount of fuel/air mixture penetrating the cylinder instantly goes out unburned through the exhaust port.

Advantages of Two-Stroke Engine

Two-stroke engines have several advantages, particularly in some applications where lightweight design, simplicity, and power are essential. The following are the main benefits of two-stroke engines:

- Two-stroke engines do not have valves, making them much easier to construct and lower their weight

- two-stroke engines have a lower output in horsepower

- It fires once in every revolution, while four strokes occur every other revolution.

- Two-stroke engines can work in any position, and the oil flow is not a problem with any valves to worry about.

Related: What is Steam Engine? Its Diagram and How it Works

Disadvantages of Two-Stroke Engine

While two-stroke engines have considerable benefits, they also have significant drawbacks that limit their usage in some applications. The main drawbacks are as follows:

- The two-stroke engine has no lubrication system, making the engine parts wear out faster.

- Two-stroke consumes much oil; it would burn a gallon every 1000 miles if it were in a car.

- It uses more fuel.

- Two-stroke engines produce a lot of pollution.

- Fuel can easily escape from the chamber through the exhaust port.

- Two-stroke engines are always dirty due to the escaped air/fuel around the outboard.