A wire rope is a multifaceted mechanical device that functions in tandem with numerous moving components to assist in the movement and support of an object or load. To connect to a load and move it in a controlled manner, wire rope is supplied with swivels, shackles, or hooks and fastened to a crane or hoist in the lifting and rigging industries.

A rope drive is a type of belt drive that is used for mechanical power transfer. Several circular section ropes are used in rope drives rather than just one flat or one V-belt. When a large power needs to be transferred over a long distance between pulleys, rope drives are frequently used.

Well, in this reading, we’ll explore what wire rope is. its applications, functions, diagram, material, constructions, identification and nomenclature, coating, and lubricant.

Let’s begin!

Learn about Lead with this detailed guide!

What Is a Wire Rope?

Wire rope is made up of multiple strands of metal wire coiled into a helix to make a composite rope. It is a complex mechanical system with several moving pieces that work together to support and move an object or load.

To attach to a load and move it in a controlled way, wire rope is equipped with swivels, shackles, or hooks and fastened to a crane or hoist in the lifting and rigging industries. It can also be used as a support system for towers or suspension bridges, as well as for lifting and lowering elevators. Moreover, wire rope is a popular lifting tool.

For its unique shape, it uses many steel wires strung in a spiral pattern around a central core. It is strong, flexible, and can handle bending stresses because of the way it is built. Furthermore, wire rope is defined as having a diameter greater than 3/8 inch (9.52 mm), while lesser gauges are referred to as cables or cords.

While wire ropes were originally made mostly of wrought iron, they are now primarily made of steel. Cold-drawn wires are used to make wire ropes because they are stronger and last longer.

Notably, the wire rope gets stronger as it gets smaller. Iron, cast steel, extra-strong cast steel, steel, and alloy steel are the materials used to make wire ropes, ranked in order of increasing strength. Sometimes, copper, brass, aluminum alloys, and stainless steel can also be used to make wire rope.

History Of Wire Rope

Wilhelm Albert, a German mining engineer from Clausthal in Lower Saxony, developed modern wire rope for usage in the Harz Mountains between 1831 and 1834. As soon as it proved to be stronger than the previously utilized ropes made of hemp or metal chains, it gained widespread acceptance.

Three strands, each with four wires, made up Wilhelm Albert’s initial ropes. Scotsman Robert Stirling Newall made more improvements to the method in 1840. John A. Roebling made his name in the American suspension bridge industry by manufacturing wire rope in 1841.

Learn about copper with this detailed guide!

Applications

Below are the applications of wire ropes:

- Wire rope is used in machinery, structural applications, and lifting tasks.

- Its type, size, and specifications are tailored to its intended use.

- Wire rope is used in aircraft cockpits to connect pedals, levers, and connectors, facilitating power transmission.

- It is used to manage propeller pitch, cowl flaps, and throttle operations and reduces vibrations.

- Wire rope is used to reinforce tires, enhancing their durability and strength.

- It plays a crucial role in supplying materials, moving heavy loads, and positioning equipment in automotive production.

- Wire rope is most widely used in the home due to its strength, durability, and resilience.

- It is cost-effective, readily available, easy to install, and simple to maintain.

- Wire ropes are essential in the search and production of crude oil, used for lifting drill bits, inserting shafts, and supporting oil rigs.

- Heavy-duty wire ropes are used in cable cars, where they are pulled by a central motor from various locations.

- Wire ropes are used in lifting and moving heavy loads in the food and beverage industries.

- Wire ropes are used in construction and safety, providing a safe and enjoyable experience for visitors.

- Wire ropes are used in modern movies for safely executing stunts.

- In live theater, wire ropes are essential for raising and lowering curtains, supporting overhead rigging, and securing backdrops and scenery.

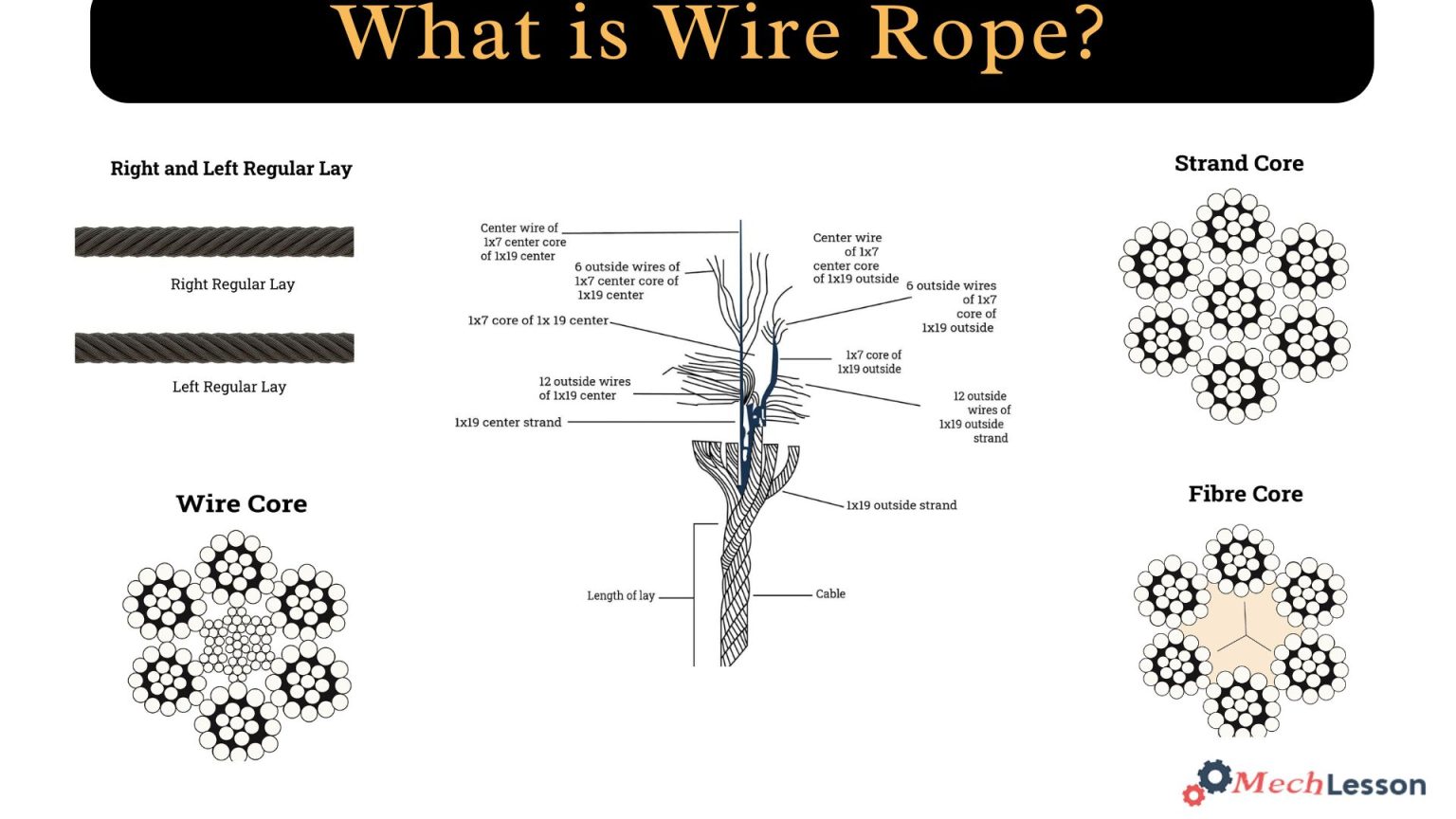

Diagram

Wire Rope Classification

The following are classifications of a wire rope:

- Cross or Regular Laying Ropes: The direction in which the wires twist in these kinds of ropes is the opposite way from the one in which the stand twists.

- Parallel or long-lay ropes: The direction of rotation of the strands in these ropes is identical to that of the ropes themselves. Despite the improved bearing surface, these ropes are prone to splitting and twisting under strain.

- Composite or reverse-laid ropes: These ropes are made by rotating the wires in two neighboring strands in the opposite direction.

Learn about Graphite with this detailed guide!

How is Wire Rope Made?

Wire rope is a type of mechanical tool designed for heavy lifting tasks, consisting of a complex assembly of moving parts. Its design allows for clearance between strands, allowing each strand to move and adjust as the rope bends.

The three basic components of wire rope are the wire, strand, and core, which are wound together to create the rope. Wire is the basic element of wire rope, typically made from steel, stainless steel, and galvanized wires. Other options include aluminum, nickel alloy, bronze, copper, and titanium.

The choice of wire depends on the type of work and its strength, flexibility, and abrasion resistance. Galvanized steel is coated with zinc to protect against corrosion and offers a cost-effective alternative.

Stainless steel wire rope retains the fundamental qualities of galvanized and general wire rope but adds corrosion and rust resistance, making it ideal for harsh conditions. Steel wire rope is the most common type used in industrial, manufacturing, and construction applications.

The tensile strength of the steel wire used to make wire ropes varies between 1200 and 2400 MPa. Ropes with exceptional strength and longevity are made by cold-drawing wires that have undergone a specific heat treatment. Steel wire ropes are made by specialized machinery.

To make a rope, the wire is first wound into a strand using a number of strands—7, 19, or 37—and then twisted around a core or center. Typically, 6 or 8 strands are used for this process. Some possible core materials are hemp, jute, asbestos, or pliable steel wire.

When the ropes are exposed to radiant heat, like when cranes are working near furnaces, asbestos or soft wire cores are employed. Having a wire core makes the rope less flexible; thus, it’s only utilized in situations when it’s subjected to extreme compressions. Example: a rope drum with many layers wound on it.

Learn about

Wire Rope Clamp

After a length of wire rope has been looped back to form an eye, it can be clamped at the loose end using a wire rope clip, which is also known as a U-bolt clamp or simply a U-bolt clip.

A U-bolt and two nuts fasten a saddle to these fasteners. Two or three wire rope clips are typically required to effectively fasten the ends of wire rope to the length of the rope in a wire rope assembly.

Construction and Materials

Wire rope is a versatile material that can be made into various types, including seven-wire rope, which has a single central strand surrounded by six others. The construction of wire rope is influenced by the number of strands and the number of wires in each strand.

The Warrington pattern, for example, is a common type with alternating sizes of large and small wires, while the Seale pattern wraps smaller diameter wires around the core.

Strand patterns are another important aspect of wire rope construction. The centerless strands have equal wires wound together to form a helical shape, while single-layer strands incorporate a single wire core surrounded by multiple wires wound around its circumference.

Multiple-layer strands arrange wire layers successively, with each layer placed evenly on top of the previous one. Seale, Warrington, filler, and flattened strand patterns all have a core that supports the wound strands, maintains their position, acts as an effective lubricant carrier, and provides overall support.

The core of a wire rope can be made from various materials, such as synthetic fibers, natural fibers, a single strand, or another wire rope. Fiber cores are restricted to light loads and are not used in severe, harsh, or stressful conditions.

Independent wire cores consist of a smaller wire rope itself, used in situations where the rope will face exceptional resistance and crushing. Wire rope lays are more complex and involve several considerations. The term “lay” describes three main characteristics of wire rope: direction, relationship, and linear distance.

There are three types of lays: regular or ordinary, lang, and alternate. Regular lay spirals the wires and strands in opposite directions, while Lang lay spirals both wires and strands in the same direction. Alternate lay combines regular and Lang lays and is used only for specialized applications.

You should also learn about Fibre Reinforced Plastic with this detailed guide!

Advantages of the Wire Rope

The following are the advantages of the wire rope:

- Wire rope might be less resistant to bending fatigue.

- Better crushing resistance.

- Decreased mechanical stress on the rope and sheave means that the sheave and winch drum will last longer.

- Increased durability and pliability.

- Multilayer spooling reduces damage between adjacent wraps, resulting in improved winding on drums.

- Reduced rope abrasion and extended service life with less maintenance expense result in a significant decrease in cost.

- When compared to a similarly sized and classified round-stranded wire rope, their strength is significantly higher.

FAQs

What is wire rope called?

The term cable is often used interchangeably with wire rope. However, in general, wire rope refers to diameters larger than 3/8 inch. Sizes smaller than this are designated as cables or cords. Two or more wires concentrically laid around a center wire is called a strand.

What is the function of wire rope?

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators and for the transmission of mechanical power.

What are the three types of wire rope?

There are three different wire rope types, each with its own properties and applications:

Stainless steel wire ropes.

Galvanized wire ropes.

Coated wire ropes.

What is another word for wire rope?

“Cable,” which is short for “aircraft cable,” is also a term used interchangeably with wire rope, though it is more often applied to wire ropes of ⅜” and smaller diameter.

What is the difference between wire and wire rope?

Wire rope is bigger than 3/8 inch, while smaller sizes are called cables or cords. They’re used in everything from small tools to big bridges, showing their strength and flexibility.

Wire ropes are made of many metal wires wrapped around a core, usually carbon steel. They come in designs like 7×19 and 7×7.