In internal combustion engines, the Zenith carburetor is an outdated fuel injection technique that has been superseded by fuel injectors. It is a traditional way of fuel mixing, even though it has no beginning problems and provides a rich mixture at high speed. Well, in this reading, we’ll explore what a zenith carburetor is, its parts diagram, construction, and how it works.

Let’s begin!

Learn about Carburetor with this detailed guide!

What is a Zenith Carburetor?

The Zenith carburetor is an old method of fuel injection in internal combustion engines that has been replaced by fuel injectors. Although it has no starting issue and offers a rich mixture at high speed, it’s only a conventional method of fuel mixture. Zenith carburettors are found on aircraft and marine engines.

They are common on farm tractors and in some commercial vehicles. Zenith company still produces a different model of carburettors today for various applications.

Zenith Carburetor was a manufacturer of gasoline engine management systems and components, primarily carburetors and filters, in the United States. It is a well-known British carburetor that is utilized by a number of well-known companies.

Zenith Carburetor Company was founded in 1910. There is no starting problem with this carburetor, and it also offers a rich mixture at high speeds.

Parts

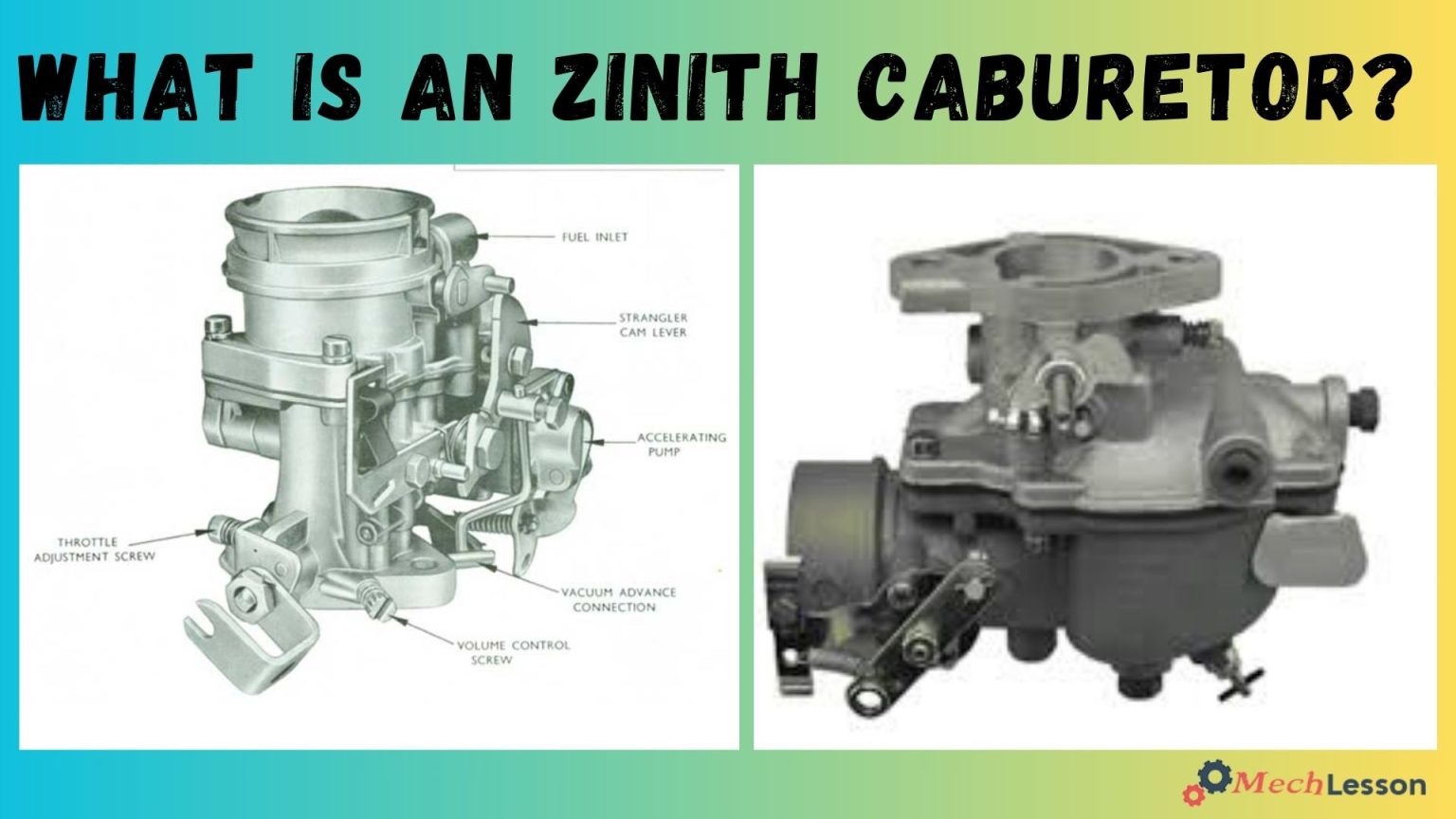

Zenith carburetors consist of the following parts:

- Float Chamber

- Main Line

- Main Jet

- Compensating Jet or Auxiliary Jet

- Starting Jet

- Reservoir or Auxiliary Chamber

- Choke

- Throttle Valve

You should learn the Difference Between Fuel Injection And Carburetor with this guide!

Construction

The float chamber is connected to the Venturi by the main line in this carburetor. The primary purpose of the fuel chamber is to draw fuel from the fuel tank. There are two balls, two floats, and a spindle in this fuel chamber.

When the throttle is closed, the airflow to the carburetor is restricted. A throttle valve is a valve that connects the carburetor to the engine and opens when the engine requires fuel.

Through the main jet, fuel from the mainline is mixed with air to generate an air-fuel combination. Aside from the main jet, there is also a compensating jet that compensates when the engine requires extra fuel at high speeds.

The fuel for this compensating jet comes from a reservoir or an auxiliary valve. Aside from the compensating jet, it also has a beginning jet that assists the engine during startup. Fuel can also be obtained via a reservoir or an auxiliary valve.

Diagram

Learn about Lean Burn and Rich Burn Engine with this detailed guide!

How Does a Zenith Carburetor Work?

The workings of a zenith carburetor are less complex and can be easily understood. When no fuel is needed, fuel from the fuel tank enters the float chamber through a route that is blocked by a spindle in the float chamber. The fuel supply to the fuel chamber is blocked and unblocked by this spindle, which rotates up and down.

When the fuel flow to the fuel chamber is reduced, the two floats drop, along with the two balls. Because the balls and the spindle are connected like a seesaw, when the balls fall, the spindle rises, clearing the fuel channel to the fuel chamber.

On the other hand, as the fuel supply in the fuel chamber increases, the two float, and the balls rise as well. Because of the seesaw link between the balls and the spindle, when the balls rise, the spindle falls. The path is stopped when the spindle falls down, and the fuel supply to the fuel chamber is cut off.

When the engine is at low speed, the choke is opened, and the air travels through the venturi, increasing the velocity of the air while decreasing the pressure. Because the fuel chamber has a high pressure due to air pressure while the venturi has low pressure.

As a result, fuel flows from high to low pressure, i.e., from the fuel chamber to the mainline, where it is mixed with air from the Main Jet. This gasoline combines with air from the choke to create a mixture.

This mixture has a 15:1 ratio, with 15 being air and 1 being fuel. After going via the throttle valve, which is just slightly opened at low speeds, this mixture reaches the engine.

When a vehicle travels at a high pace, the engine speed increases, resulting in increased suction. More fuel is delivered by the main jet due to the higher suction at the venturi, and fuel is also supplied by the compensating jet or auxiliary jet.

The fuel for this auxiliary jet comes from the auxiliary valve. However, because the fuel stored in the auxiliary valve or reservoir is limited and empty at high speeds, the compensating jet can only supply fuel for a limited time.

Because there is an aperture between the reservoir and the fuel chamber, this reservoir takes a long time to store the gasoline. Because of the hole, very little gasoline can travel from the fuel chamber to the reservoir. As a result, at high speeds, fuel is sprayed from both the main and compensating jets for a short period of time.

You should learn about Intake Manifold with this detailed guide!

The throttle valve is virtually closed when the engine is started. At the time of starting, there is a very small space for the fuel to travel through the throttle valve. The engine requires a rich mixture in order to start.

The air from the air filter passes through the gap in the side of the throttle valve, increasing the velocity of the air and decreasing the pressure of the air on the upper side of the throttle valve, resulting in a suction effect at the starting jet, which is located at the top of the throttle valve.

The fuel for this starting jet comes from the same reservoir as the fuel for the compensating jet.

Conclusion

The Zenith carburetor stands out as a durable and reliable fuel delivery system that has served countless vehicles and machinery for decades. Known for its simplicity, ease of maintenance, and consistent performance, the Zenith carburetor is still appreciated in vintage engines, tractors, and classic automobiles.

Understanding how it works, its components, and how to properly adjust or troubleshoot it can significantly enhance engine performance and longevity. Whether you’re restoring an old vehicle or maintaining farm equipment, the Zenith carburetor remains a timeless piece of engineering worth knowing.

You should learn about Best Carburetor Cleaner with this detailed guide!

Frequently Asked Questions (FAQs)

What is a Zenith carburetor?

A Zenith carburetor is a type of carburetor used in internal combustion engines to mix air and fuel in the proper ratio for combustion. It was widely used in older vehicles, tractors, and industrial engines.

What makes the Zenith carburetor unique?

Zenith carburetors are known for their straightforward design, reliability, and ease of adjustment. Many models feature a downdraft design with separate circuits for idle, mid-range, and high-speed fuel delivery.

What engines use Zenith carburetors?

Zenith carburetors were commonly used in classic cars, agricultural machinery, stationary engines, and military vehicles, especially during the early to mid-20th century.

How do you adjust a Zenith carburetor?

Adjustment typically involves tuning the idle mixture screw and idle speed screw while the engine is running. Always refer to the specific model’s service manual for proper procedure and settings.

How do I identify my Zenith carburetor model?

Look for a model number or identification tag stamped on the carburetor body. This is essential for sourcing the correct rebuild kits or replacement parts.

Can I rebuild a Zenith carburetor myself?

Yes. With basic mechanical skills and the proper rebuild kit, most Zenith carburetors can be disassembled, cleaned, and rebuilt at home.

Are Zenith carburetors still made today?

While most original Zenith carburetors are no longer manufactured, rebuild kits and aftermarket replacements are widely available for many models.

What are common problems with Zenith carburetors?

Typical issues include clogged jets, worn gaskets, vacuum leaks, and incorrect float level—all of which can usually be addressed with a thorough cleaning or rebuild.

Are Zenith carburetors still made?

Today, the company is known as Zenith Fuel Systems LLC, with headquarters and a modern manufacturing facility in Bristol, Virginia, and still offers original manufacturing equipment and replacement carburettors and kits.

How do you identify a zenith carburetor?

The first step in identifying a Zenith carburetor is to find the model number. This is usually stamped on the side of the carburettor body or can be found on a metal tag attached to the carburetor. Some Zenith carburettors may also have the model number stamped on the throttle body.

What are the Parts of a Zenith Carburetor?

The Zenith carburetor has 8 main components: a float chamber, main line, main jet, compensating jet, starting jet, reservoir, choke, and throttle valve. It works by drawing fuel from the float chamber through the main jet at a low-speed air-to-fuel ratio of 15:1.