A downdraught carburettor is a Solex carburettor, which is mostly used in car engines. As previously stated, the basic carburetor’s fundamental disadvantage is that it only maintains one air-fuel ratio at one throttle position.

This Solex carburetor may offer a rich mixture when the engine needs to start and a lean mixture when the vehicle is cruising (travelling at a steady, economical speed).

This carburetor includes multiple fuel discharge circuits to supply varied mixtures for various operating conditions such as engine starting, idling, low-speed operation, normal operation, and acceleration.

Well, in this reading, we’ll explore what a Solex carburetor is, its construction, parts, diagram, types, and how it works. We’ll also explore its advantages and disadvantages.

Let’s begin!

Learn about Carburetor with this detailed guide!

What is a Solex Carburetor?

Solex carburetors are used in passenger automobiles and commercial vehicles and are widely employed by various European manufacturers. The Solex carburetor is a variant of a standard carburetor.

Marcel Mennesson and Maurice Goddard founded the solex carburettor.

The standard carburetor performs admirably under regular operating settings but not so effectively in extremes such as the winter and summer seasons, idling situations, or fast acceleration. The solex system performs admirably in these circumstances.

This carburetor includes separate fuel circuits for starting, idling, accelerating, and low-speed operations, among other things. Provisions on the Solex carburetor ensure a richer mixture at start-up and a weaker mixture while the engine is cruising.

Construction

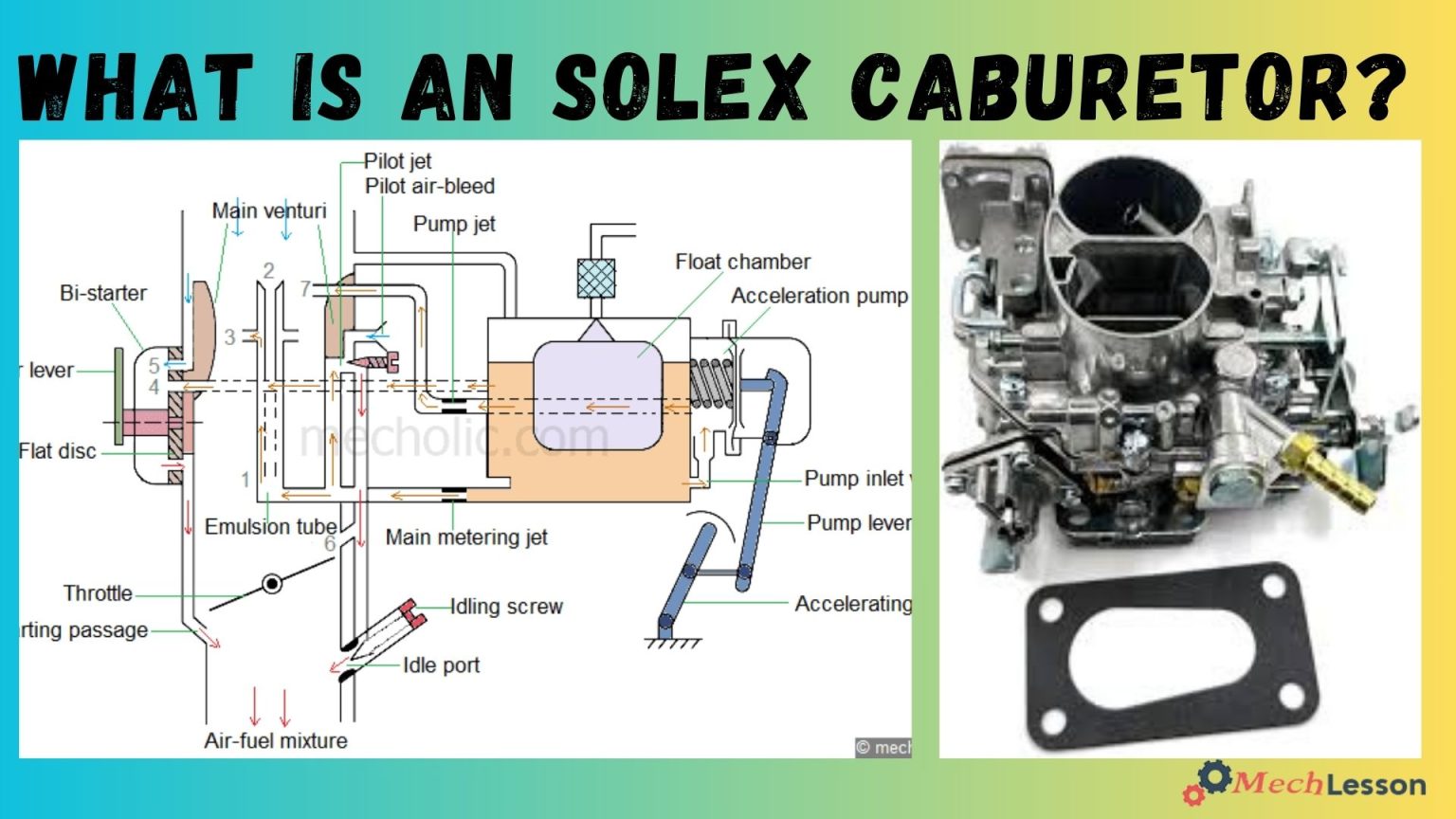

The fuel chamber in a solex carburetor receives fuel from the fuel tank and stores it in the carburetor to create an air-fuel combination. The fuel level in the fuel chamber is maintained by a float in this fuel chamber.

The gasoline venturi travels through a mainline to reach the throat tube. The main jet, which is placed at the end of the mainline, feeds fuel into the venturi throat duct. When the choke opens, the fuel from the main jet evaporates.

When the throat valve is opened, fuel from the main jet is combined with air that comes in when the choke is opened to generate an air-fuel mixture, which then enters the engine cylinder.

Apart from the main jet, the engine cylinders are supplied with gasoline by three additional pipelines: pilot jets, pump jets, and beginning channels.

The fuel for the pump jet comes from the acceleration pump, whereas the fuel for the pilot jet comes from the main jet. The pipeline for the pilot jet is isolated from the main line.

An accelerator pedal is used to operate the acceleration pump. During acceleration, these acceleration pumps are used. During idle or no-loads conditions, the pilot jet is used. It has a pilot bleed opening, which connects the pilot jet to the air, allowing an air-fuel mixture to form.

An idle screw near the end of the idle position pipeline controls the quantity of air-fuel mixture that enters the engine cylinder.

You should learn about Best Engine Degreaser with this detailed guide!

Parts and Diagram

Types of Solex Carburetor

Solex carburettors are classified into three main categories.

- according to its type,

- according to the bore of the throttle chamber and

- according to its model.

The Solex carburetor is classified according to the direction of flow through the carburetor.

- Updatable Carburetor.

- Horizontal Carburetor.

- Downdraught Carburetor.

According to the layout of the induction system

- Simple carburetor for single induction manifold.

- Dual Port Carburetor for two induction manifolds.

- Dual-port compound carburetor for the single-induction manifolds

You should also learn about Zenith Carburetor with this detailed guide!

How Does a Solex Carburetor Work?

In the working of a Solex carburetor, the fuel enters the fuel chamber before being blocked by barriers once the proper amount of fuel has entered the fuel chamber.

When the fuel level in the fuel chamber reaches the maximum level in the fuel room, the float that stops the passage between the fuel tank and the fuel chamber raises the fuel level in the fuel chamber and blocks the passage.

Let’s discuss the different circuits with different operating conditions:

Engine Normal Running

- The fuel will be discharged into the venturi throat tube by the main metering jet.

- The fuel from the main metering jet will be injected into the air-bleed emulsion system, which has lateral holes.

- The air entering through it is calibrated by the air correction jet, which guarantees that the air-fuel balance is maintained.

- The spraying aperture or nozzles deliver the measured emulsion of fuel and air. These nozzles are drilled horizontally on the choke tube’s vertical pipe.

- The air-fuel mixture quantity delivered into the engine is controlled by a throttle valve at the end of the tube. The traditional butterfly valve is another name for this valve.

This circuit allows the engine to run normally with this Solex carburetor. However, for the engine’s other operating circumstances, we’ll use separate fuel circuits for different running states.

You should also learn about The Difference Between Fuel Injection And Carburetor with this detailed guide!

Cold-starting and warming

The Bi-Starter, often known as the progressive starter, is the principal benefit of the Solex Carburettor. The engine requires a richer mixture at first, and the mixture is designed to be low once the engine has started. As a result, the engine will be started by this progressive starter.

This starter comes in the shape of a flat disc with various-sized holes. The holes in the starter disc connect the starter petrol jet and the starter air jet, which open into a tunnel below the throttle valve.

A starting lever adjusts the hole diameters so that the correct amount of fuel and air is delivered to the engine cylinder during the suction stroke.

We will close the throttle and deliver the air-fuel mixture from the beginning channel, which has a richer mixture from this Bi-Starter system when we start the engine. We must warm up the engine by accelerating a few times before releasing the throttle valve and passing the lean/normal mixture down the venturi throat.

Idling and Slow Running of the Engine (Cruising)

The engine is idling when it is not producing any work and merely supplying enough power to its auxiliaries.

Because the cylinder pressure is lower during idling or slow running, a rich mixture is required, and because the cylinder pressure is lower, there is a risk of re-sucking of the exhaust gases, causing poor combustion and causing the engine to stumble. As a result, this rich mixture aids in making the process go smoothly.

You should also learn about The Best Carburetor Cleaner with this detailed guide!

Acceleration of Engine

As shown in the schematic design, the engine acceleration and supplementary acceleration pump injector equipment are located on the right side of the floating chamber.

With the help of the acceleration pump injector immediately on top of the venturi, this acceleration pump will provide more fuel for the engine.

Carburetor operation is the same as normal, but with the additional fuel drops, the engine becomes excited when we press the accelerator pedal. The accelerator pump sucks the fuel from the float chamber and stores it for the next pedal movement when you let off of the pedal.

Advantages of Solex carburetor

The following are the benefits of the Solex carburetor in its various applications:

- For different scenarios, all circuits work differently.

- It cuts down on waste and carbon emissions.

- The throttle response of this carburetor is superior to that of another carburetor.

- It performs admirably in situations requiring rapid acceleration.

- It gets off to a great start.

Learn about Multi-Point Fuel Injection System with this detailed guide!

FAQs

What is a solex carburetor?

The Solex Carburetor is a starting circuit or bi-starter to provide a rich mixture at the time of starting. The main function of the by-starter is to compensate for the problem encountered while starting the engine, especially in the winter season. This gives the engine a rich mix at the time of starting.

How do I identify my Solex carburetor?

The type of carburetor IS recognized by the lettering and numbers stamped on the outside of the float chamber.

What is the difference between solex and a simple carburetor?

The Solex carburetor has a more complex design compared to a simple carburetor. It has more components and is designed to provide better fuel efficiency and performance. The Solex carburetor uses a different method of fuel delivery compared to a simple carburetor.