A ball valve is a flow control device that regulates the flow of liquid by use of a hollow, perforated, pivoting ball. When the ball’s hole aligns with the flow inlet, it is open; when the valve handle rotates it 90 degrees, the flow is blocked.

A ball valve is a kind of quarter-turn shut-off valve that contains a hollow, perforated, pivoting ball inside the valve that regulates the flow of a gas or fluid.

Well, in this reading, we’ll explore what a ball valve is, its applications, parts, construction, diagram, types, and how it works. We’ll also explore its advantages and disadvantages.

Let’s begin!

You should also learn about Spring Check Valve with this detailed guide!

What is a Ball Valve?

A ball valve is a type of quarter-turn valve that controls flow by use of a rotating ball that has been drilled through. Fluids or gases can flow through the hole when it is aligned with the direction of flow.

On the other hand, the flow is entirely stopped when the ball is rotated 90 degrees.

Ball valves are very durable and ideal for uses requiring simple on/off operation. They are robust and continue to function reliably even after many uses.

The handle functions as a visual indicator of the valve’s condition in either situation. The valve is open if the handle is parallel to it. On the other hand, the valve is closed if the handle is perpendicular.

Furthermore, they close safely even after extended periods of rest and exhibit outstanding dependability. Another way to regulate flow rate is to open or close the valve to different degrees.

Because of these characteristics, they are a great alternative to gate and globe-type valves for shutdown and control applications. For throttling applications, ball valves do not, however, provide the finite control that these other valves do.

Applications

Ball valves are used as fluid shutdown valves in onshore and offshore oil and gas production facilities. Another primary use of ball valves is to supply furnaces using fuel gas systems. With the least amount of pressure loss, ball valves can regulate the flow of high-pressure gases and liquids.

Ball valves are used to completely shut down fluid flow, and they provide full flow in a pipeline. They are also ideal for flow regulation, and the application can be in fully closed and completely open positions.

A ball valve can also be used with larger pipe diameters because of its less complex construction. They are used in oil and gas applications, marine, aerospace, water supply stations, gas stations, etc.

You should also learn about EGR Valve with this detailed guide!

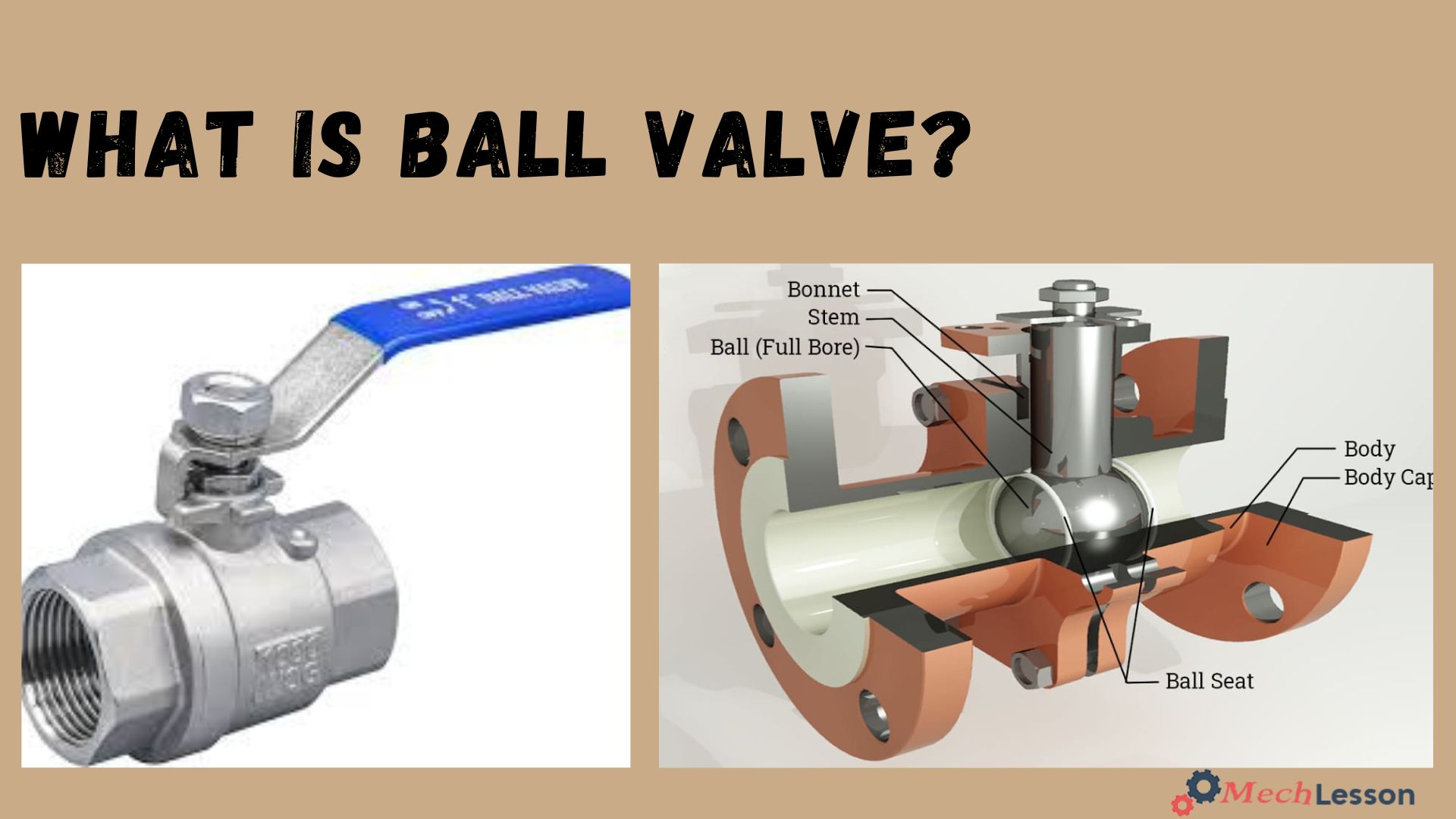

Parts of a Ball Valve

The major components of a ball valve include the valve body, rotary ball, stem, seats, power supply, packing, and bonnet.

The valve body is the main part of a valve, containing components for on/off control. It contains a rotary ball with a centre bore, which is controlled by turning the stem. The stem connects the ball to an external control mechanism, such as a handle or lever.

Seats are discs between the body and the ball, providing a seal and support. The stem rotates using manual or actuated power sources, including manual or automated options.

Packing seals the stem to prevent media escape. Also, the bonnet, which contains the stem and packing, is the part of the body that contains the stem and packing.

Diagram

You should also learn about Globe Valve with this detailed guide!

Types of Ball Valve

Below are the general types of ball valves:

- Full Port Ball Valve

- Standard Port Ball Valve

- V Port Ball Valve

- Trunnion Ball Valve

- Manually Operated Ball Valves

Full Port Ball Valve

A full port ball valve reduces friction loss by having an enlarged ball with a hole the same size as the pipeline. The valve is bigger, yet the flow is unrestricted.

Standard Port Ball Valve

A standard port type of ball valve is typically less costly and has a smaller ball and a smaller port. There is a small restriction in flow since the flow through this valve is one pipe size less than the valve’s pipe size.

The reduced port ball valves restrict flow because the flow through the valve is one pipe size less than the valve’s pipe size.

V Port Ball Valve

A V-port ball valve, also known as a Venturi port. It features a “V”-shaped seat or a “V”-shaped ball. This enables a more regulated opening and closing of the orifice with a flow profile that is closer to linear.

The small end of the “V” is opened first when the valve is in the closed position and opening is initiated, providing steady flow control during this phase.

Since a normal valve would be quickly damaged by the greater fluid velocities, this kind of design requires a more robust construction.

Trunnion Ball Valve

A trunnion ball valve is a kind of ball valve often used on bigger and higher-pressure valves (such as 4 inches and above 600 psi and above). It has a mechanical method of attaching the ball at both the top and the bottom.

Learn about PCV Valve with this detailed guide!

Manually Operated Ball Valves

Manually controlled ball valves can collapse fast, which is why water hammer is a risk. Certain ball valves come with an actuator that can be powered by an electric motor or pneumatics.

Both flow control and on/off operation are possible with these valves. A positioner is another feature of a pneumatic flow control valve that converts the control signal into actuator position and opens the valve appropriately.

Other types of ball valves based on the housing include:

- Single Body or One-Piece Ball Valve

- Two-Piece Ball Valve

- Three-Piece Body Valve

- Top Entry Valve

- Side Entry Ball Valves

- Welded Body Ball Valves

How Does a Ball Valve Work?

In the working of a ball valve, a shut-off valve rotates a ball with a bore within the valve for 90 degrees, allowing or blocking the passage of liquids and gases in a pipe system. The ball has a stem connecting it to the working and control mechanism that turns it, and it is positioned against two seats.

The fluid is not allowed to flow through the valve when the bore’s cross-section is perpendicular to the flow area. If not, the fluid escapes via the valve.

Along with butterfly and plug valves, ball valves are also quarter-turn valves. In pipe systems, they are extensively utilized. They can be used with an actuator or manually driven. A wrench or a lever that is physically controlled by an operator is the most basic way to operate a ball valve.

To open or close the valve, a force is provided to move the lever arm 90 degrees in either a clockwise or anticlockwise direction. The valve is said to be open if the lever arm is parallel to the pipe. Conversely, a closed valve is indicated if the lever arm is perpendicular to the pipe.

A ball valve can only be used in shut-off and on phases. Ball valves are not recommended for throttling since they do not have precise controls for regulating flow rate.

You should learn about Needle Valve with this detailed guide!

Advantages and Disadvantages of Ball Valve

Ball valves are a popular choice due to their efficiency, affordability, durability, ease of use, versatility, and strength. They don’t require lubrication and offer a bubble-tight seal with low torque.

They can be purchased at lower costs than comparable products, and they are less prone to damage. They are easy to install and handle, making them suitable for various industrial applications.

Ball valves can maintain high pressure, volume, and temperature flow. They are also simple to repair, as they can be easily accessed when needed. However, they have some disadvantages, such as poor throttling characteristics and wear and tear when used incorrectly for certain fluids.

These disadvantages make them not recommended for sustained throttling applications and can cause valves to wear or become damaged. Overall, ball valves are a versatile and cost-effective choice for various industrial applications.

FAQs

When would you use a ball valve?

Ball valves are recommended for applications that require frequent, quick control over the flow of liquid. Water hammer: Because ball valves can open and close immediately, they are more likely than gate valves to cause water hammer.

What is the use of ball check valve?

Ball check valves are designed to prevent backflow in pipeline systems, making them a critical component in many installations. Ball check valves are often installed at the pump outlet to safeguard the pump and are widely used in wastewater systems, as well as in irrigation networks and fire protection applications.

What is ball valve vs needle valve?

Ball valves are designed for on-off operation. Avoid extended periods of throttled operation. Needle valves offer flexible flow control options with designs allowing on-off, throttling, and fine metering operation depending on your needs.

What is the main function of a ball valve?

A ball valve is a flow control device that uses a hollow, perforated, and pivoting ball to control fluid flowing through it. It is open when the hole through the middle of the ball is in line with the flow inlet and closed when it is pivoted 90 degrees by the valve handle, blocking the flow.