Brazing is a process used to join metal surfaces by allowing molten metal to flow into the joint. Unlike welding, this ancient method doesn’t melt the base metal when joining.

It requires very close-fitting parts and uses a higher temperature than other joining methods. The filler metal flows into the parts through capillary action, preventing workpieces from melting.

Well, in this reading, we’ll explore what brazing is, its diagram, techniques, types, and how it works. We’ll also discuss brazing flux, filler metals, and their difference from soldering and welding.

Let’s begin!

Learn about soldering in this detailed guide!

What is Brazing?

The technique of brazing involves melting and depositing a filler metal—which has a lower melting point than the metal— into the joint to connect two or more metal objects.

Brazing differs from welding in that it does not involve melting the work parts during the process. Brazing is different from soldering in that it involves considerably closer-fitting pieces and a higher temperature.

By capillary action, the filler metal enters the space between closely fitting pieces during the brazing process. The filler metal is heated just above its melting point, or liquidus, under the protection of an appropriate atmosphere—typically a flux.

After that, in a procedure called wetting, it pours over the base metal and cools to fuse the work parts together. The ability to combine metals—either the same or different—with significant strength is one of brazing’s main benefits.

Brazing parts is crucial for achieving high-quality joints, requiring clean, oxide-free base metal surfaces. Joint clearances of 0.03 to 0.08 mm are recommended for optimal capillary action and joint strength. Cleanliness of brazing surfaces is essential for proper wetting, as contamination can cause poor flow.

Cleaning methods include chemical and abrasive or mechanical cleaning, with mechanical cleaning requiring proper surface roughness to ensure wetting on rough surfaces is more readily occurring. Surface cleanliness also significantly influences joint strength.

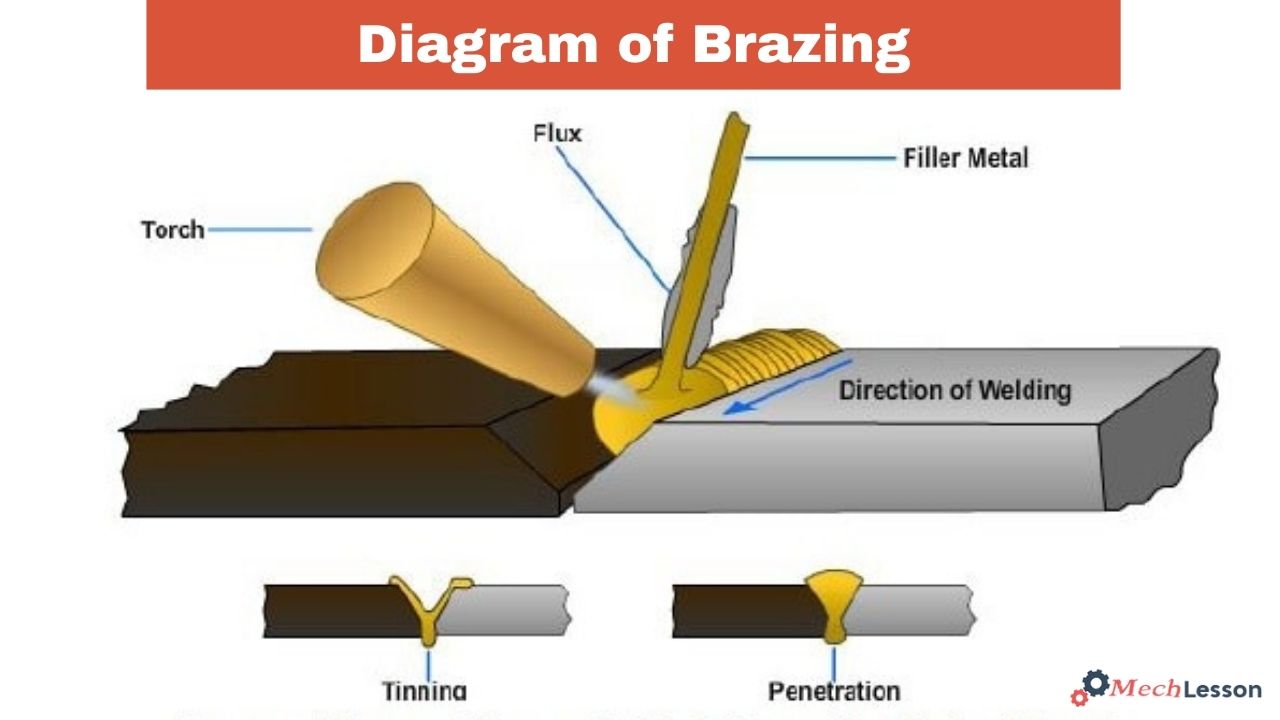

Diagram

You should also learn about pipe joint with this guide!

Brazing Techniques

There are two heating methods of brazing, such as localized and diffuse heating.

The Localized Heating Method

Torch brazing is a technique used for heating and melting filler metals, primarily used in small production assemblies with unequal metal weights. This technique requires flux to protect joints and post-cleanup.

Induction brazing uses high-frequency alternating current to heat the workpiece and melt filler material. Resistance brazing generates heat from the electrical resistance of the brazing alloy, ideal for creating simple joints between highly conductive metals.

The Diffuse Heating Method

Furnace brazing involves gas firing or heating elements to heat the furnace to the desired temperature and applying brazing filler metal to join surfaces. This process allows for accurate control of heating and cooling cycles, often performed in a vacuum to protect the alloy from atmospheric conditions.

Dip brazing involves immersing the workpiece or assembly in a bath of molten filler metal or molten salt and applying brazing flux to prevent oxidation and solidify it.

How Does Brazing Work?

To acquire a high-quality joint in brazing, the parts should be closely fitted, and the base metals should be clean and free from oxides. The gap between the workpieces should have a clearance of 0.03 to 0.08mm for better capillary action and joint strength.

However, achieving such clearance may not be feasible in certain operations.

Surface cleaning in brazing operations is very essential, as contamination can lead to poor wetting (flow). There are two methods for cleaning parts in brazing: chemical cleaning and abrasive or mechanical cleaning.

In the case of mechanical cleaning, it is crucial to maintain the proper surface roughness, as wetting occurs more frequently on a rough surface compared to a smooth surface of the same geometry.

The brazing temperature generally must be above the melting point of the filler metal when considering the impact of temperature and time on the quality of brazed joints. As the temperature of the braze alloy increases, the alloying and wetting action also increase.

In some situations, a higher temperature must be implied to accommodate some factors, like allowing the use of different filler metals, controlling metallurgical effects, or sufficiently removing surface contamination. The best temperatures usually used are

- Be the lowest possible braze temperature

- Minimize any heat effects on the assembly

- Minimize filler metal/base metal interaction

- Maximize the life of any fixtures or jigs used

The effect of time on the brazed joint will primarily affect the extent to which these effects are present. However, we expect the selected production process to minimize brazing time and associated costs. But time and cost are secondary to other joint attributes (e.g., strength, appearance) in some non-production settings.

For brazing operations to be carried out within an inert or reducing atmosphere environment (i.e., a vacuum furnace), a flux known as borax must be applied to prevent oxides from forming during the heating stage. This flux also cleans the contamination left on the brazing surfaces.

Learn how flux-cored arc welding works with this detailed guide!

What are Brazing Flux?

Brazing fluxes are available in different forms, such as flux paste, liquid, powder, or pre-made brazing pastes that combine flux with filler metal powder. The most common flux is available as thin wire and rods with a coating of flux or a flux core.

This flux flows into the joint when applied to the heated surface and melts the filler metal on the joint. Once the cycle is complete, remove the excess flux to prevent corrosion. It also impedes joint inspection and prevents further surface finishing operations.

Generally, we select fluxes based on their effects on a specific base metal. The selected flux must be chemically compatible with the base metal and the filler metal being used. less active fluxes should be used on longer brazing cycles than short brazing operations

Brazing Filler Materials

Depending on the application method and intended use, different types of alloys serve as filler metals in brazing. Brazing alloys consist of three or more metals to achieve the desired properties.

A particular filler metal is chosen for a specific project to obtain the desired properties. These may include withstanding the service conditions required, wetting the base metals, and melting at a lower temperature than the base metals.

Braze alloys are typically available as ribbons, rods, powder, cream, wire, and preforms. The application determines if the filler material is pre-placed at the desired location or applied during the heating process.

In manual brazing, rod or wire forms of filler metals are used due to the fact that they are easier to apply. There are multiple choices to be made when trying to carry out brazing, as the filler materials are of different types.

The selection of filler materials depends on the specific operation. So, the following listed below are the type of filler materials used in brazing:

- Aluminum-silicon

- Copper

- Copper-silver

- Copper-zinc (brass)

- Copper-tin (bronze)

- Gold-silver

- Nickel alloy

- Silver

- Amorphous brazing foil using nickel, silicon, copper, boron, phosphorus, etc.

Learn about arc welding with this comprehensive guide!

Difference Between Brazing and Soldering

Soldering is a technique that involves melting filler metal into a junction point to create strong and permanent bonds between metals. Soldering exhibits capillary action and operates at a temperature below 840°F, which is significantly lower than that of welding. Primary solder types and materials used include lead alloys, tin alloys, and zinc alloys.

Brazing and soldering are two processes used to join two metal parts, with brazing utilizing solder at a higher temperature range of 1200-2300 degrees Fahrenheit. Both processes involve capillary action between the base metals, which should be free from oil and dirt.

However, brazing requires higher temperatures, leading to different joint properties in service. Brazing often results in extensive interaction between the filler metal and the workpieces, while soldering allows only minimal inter-alloying.

Joint strength and fatigue resistance are two key differences between the two processes. Brazed joints are typically stronger than solder joints, but failure can occur in solder joints if they experience stress in service. In contrast, brazing joints require a higher temperature, leading to more intense metallurgical reactions and alloying.

In terms of fatigue resistance, a well-brazed joint can handle fatigue and stresses placed on it, while solder joints in similar conditions would fail due to a low degree of alloying. Understanding the differences between brazing and soldering processes is crucial for understanding their differences and ensuring proper joint performance in service.

Difference Between Brazing and Welding

Welding is a manufacturing technique used to join metal components using heat, pressure, or a combination of both. It is commonly used for joining metals, thermoplastics, and wood.

Four commonly used welding techniques are gas metal arc welding (GMAW), shielded metal arc welding (SMAW), flux-cored arc welding (FCAW), and gas tungsten arc welding (GTAW).

The major difference between brazing and welding is the addition of filler material to achieve a joint. In welding, the properties of base metals change after joining, while in brazing, they remain the same. Brazing produces stronger joints, while welding produces weaker ones.

Cleaning the workpieces is necessary before joining, but welding is not required. We use brazing to join dissimilar metals, and we use welding to join similar metals. It is suitable for small assemblies, while welding is suitable for large assemblies. Brazing joints cannot withstand high temperatures, while welding can.

You can also learn about gas welding with this guide!

Advantages and Disadvantages of Brazing

Brazing is a unique metal-joining technique that offers numerous advantages over welding. It allows for tighter tolerance control and produces a clean joint without secondary finishing. Applying it to dissimilar metals and non-metals results in less thermal distortion compared to welding.

Brazed joints can be cost-effective and coated or clad for protective purposes. Their less sensitive process parameters allow for easy adaptation to mass production and automation.

However, due to the use of softer filler metals, brazing has certain disadvantages, such as a lack of joint strength compared to a welded joint. Furthermore, high service temperatures can damage brazed joints, necessitating a high level of base-metal cleanliness.

Some brazing applications require adequate fluxing agents to control cleanliness, and the joint color may differ from the base metal, creating an aesthetic disadvantage.

Conclusion

Brazing is a versatile and effective metal-joining process that uses a filler metal with a lower melting point than the base metals. It creates strong, leak-proof, and often visually clean joints without melting the workpieces themselves.

Industries such as automotive, aerospace, HVAC, and jewelry making widely use brazing due to its ability to join dissimilar metals and complex assemblies. Proper surface preparation, appropriate filler material, and appropriate heating techniques enable brazing to produce long-lasting, high-quality connections.

FAQs on Brazing

What is brazing?

Brazing is a metal-joining process where a filler metal is melted and flowed into the joint between two close-fitting parts without melting the base metals.

How is brazing different from welding?

In brazing, only the filler metal melts, not the base materials, while in welding, both the filler and base metals are melted to form a joint.

What types of materials can be brazed?

Brazing can join a wide range of metals including steel, aluminum, copper, brass, and even dissimilar metals.

What are the advantages of brazing?

Advantages include strong joints, the ability to join dissimilar metals, minimal thermal distortion, and suitability for complex assemblies.

Is brazing stronger than welding?

Generally, welding creates stronger joints because it fuses the base metals together. Brazed joints, however, are adequate and incredibly strong for a variety of uses.

What temperatures are typically used in brazing?

Brazing typically occurs at temperatures above 450°C (842°F) but below the melting points of the base metals.