Have you ever wondered why you can sit comfortably in your car for long periods? You might think of seats; they do play a role, but not as significantly as your vehicle’s suspension. Yes, the mess of springs and shockers sprouting out from under the car is responsible for your smooth ride.

Your car’s suspension absorbs the impact of bumps before they strike the frame, giving you a smooth ride. Furthermore, modern suspension systems can react to the type of terrain and automatically adjust to smooth or bumpy roads.

In this reading, we’ll explore what a car suspension is, its function, diagram, components, types, and how it works.

Let’s begin!

Related: What is Engine Mount? Its Causes & Replacement Cost

What Is A Car Suspension?

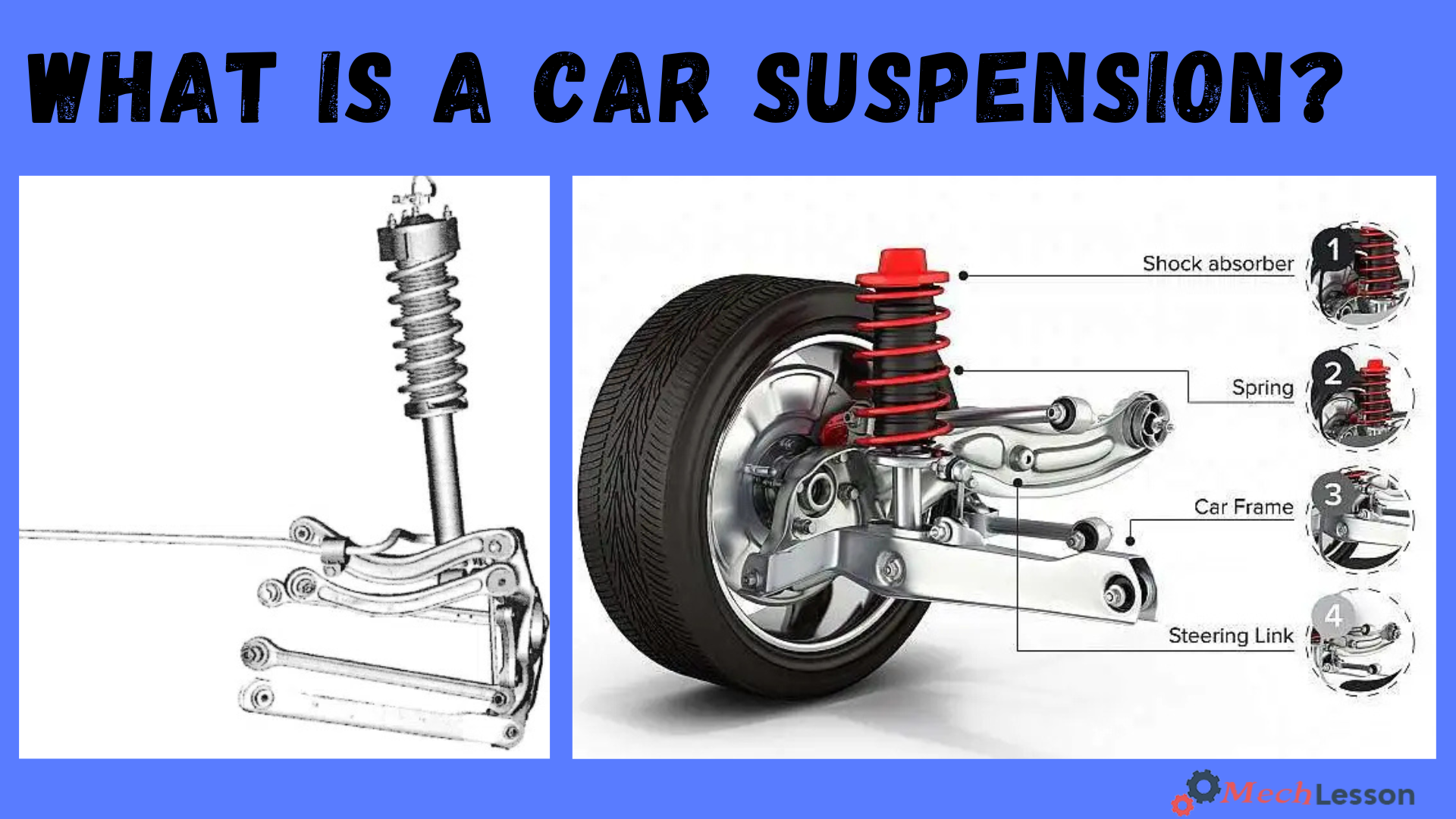

The car suspension system refers to all the parts that work together to protect them from shocks. Springs connect the automotive chassis to the axles in an indirect manner. This protects the vehicle’s body from road shocks caused by bounce, pitch, roll, or sway.

In other words, a vehicle’s suspension consists of the parts that allow the wheels and the vehicle to move relative to each other, such as tires, air in the tires, springs, shock absorbers, and links.

Suspension systems need to balance excellent road grip and control with ride comfort, which can be challenging.

Components Of A Car Suspension

A car’s suspension system protects the vehicle from road shocks by utilizing several components, which include

Shock Absorber

A shock absorber is a car suspension component that works to dampen vibrations from the road surface. It works by using a liquid, oil, to absorb shocks and vibrations. The valve opens when compression occurs, allowing oil to flow easily, and closes when expansion occurs.

Shock absorbers come in single, double-acting, twin-tube, monotube, gas, and hydraulic types, depending on their construction and working medium.

Spring

Car wheels are equipped with suspension systems that utilize springs, including coil springs, leaf springs, and torsion bar springs. These springs absorb shocks from road friction and increase traction on the road, ensuring a stable and comfortable driving experience for passengers.

Ball Joint

The ball joint accepts lateral and horizontal loads and serves as a rotation axis. It is divided into upper and lower types.

Oil is essential for lubrication, with ball joints made of molybdenum disulfide and lithium requiring oil changes, while resin holder types don’t require grease changes.

Stabilizer Bar

The stabilizer bar is a crucial component in car suspension; it ensures body balance during sudden turns due to the high speed and centrifugal force. When the car suddenly turns at high speed, the stabilizer bar helps maintain balance and prevents the car from overturning.

Stabilizer iron rods, typically of high elasticity, are connected between the lower arms of the wheels.

Bumper

A bumper is an additional component in the suspension system, ensuring suspension performance by protecting the axle, frame, and shock absorber.

Installed to prevent damage during expansion and contraction, it includes bounding and rebounding parts. The bumper is a safety device installed on the back or front of a car, with various variations depending on the model.

Upper and Lower Arm

The lower arms work alongside the upper arm to connect the knuckle arm with the car body, forming a wishbone or arm. These arms, similar to a human hand, ensure a stable car turn.

Knuckle Arm

The knuckle arm rotates the car wheel on the spindle shaft. It is connected to the lower arm using a ball joint. Maintaining the car’s suspension system requires inspections in authorized workshops and replacing damaged components immediately.

Strut Bar

The strut bar holds the lower arm for proper front wheel function. The spooring process, which involves adjusting the strut bar nut, ensures the steering wheel can turn on its own, ensuring the vehicle maintains a straight position.

Lateral Control Rod

In a four-wheeled vehicle, the lateral control rod plays a crucial role in holding the axle in place during side load. Installed between the vehicle’s axle and body, it requires regular maintenance and repair to prevent damage and hinder performance.

Related: 7 Causes and Solution of a Popping Noise When steering

Diagram

Related: What is Coil Spring? Its Diagram and Material

Types Of Suspension System

Suspension systems vary by vehicle body type and, in certain cases, even by brand. Here are the eight most common car suspensions you’ll come across.

Independent Suspension

Independent suspension refers to a suspension system that is installed on each wheel separately. This feature means that bumps encountered by one wheel are unaffected by those experienced by the others. As a result, the ride and control are extremely comfortable.

The Macpherson Strut, Double Wishbone Suspension, and Multi-Link Suspension are some of the suspensions that use this technique.

Rigid Suspension or Leaf Spring

The leaf spring rigid suspension, like the beam axle suspension in construction, uses leaf springs instead of coil springs to act as dampers. Large bundles of spring material, primarily steel, known as leaf springs, flex when the vehicle’s axle presses against them.

Commercial vehicles find leaf springs ideal as they can effortlessly support significant weight. However, if used under conditions such as comfort, high speed, or fast turning, the suspension will alter the vehicle’s handling.

Multi-Link Suspension

This form of suspension features several links connecting to the automobile chassis and wheel assembly, as the name implies. Because these many links can respond to any force applied to them, they’re also employed in off-road vehicles.

Multi-link suspension systems on the rear tires provide a highly comfortable ride and good grip. This suspension will keep your wheels attached to the ground in the event of a rapid turn.

Due to their intricate construction, these suspensions are only found on high-end vehicles, and any damage necessitates a time-consuming and costly repair.

Rigid Axle Suspension

The rigid axle suspension, also known as beam axle suspension, has a perpendicular axle that is attached to the wheels by a wheel spindle and can be used with leaf springs or coiled springs. A stiff axle is extremely sturdy and capable of carrying a significant amount of weight.

The rigid axle suspension, unlike most current suspensions, has a basic configuration that makes it straightforward to fix and replace.

Heavy-duty vehicles and off-roaders use this suspension and its modified versions due to its load-carrying capability and improved articulation.

However, these suspensions are not designed for fast speeds or sharp turns, and if subjected to heavy cornering, the car will roll over.

Related: 7 Common Symptoms of a Bad Shock Absorber

Air Suspension System

Air suspension, often known as air springs, is a type of suspension that uses air bellows instead of coils and dampers. These air bellows can be inflated and deflated with the help of an air compressor to alter the vehicle’s ride height.

Air suspension is one of the most comfortable and load-bearing suspensions available, which is why it is found in the majority of high-end luxury and sports automobiles.

Many vehicles and buses utilize them because of their weight-carrying capabilities. Air suspensions are extremely adaptable, and when combined with an onboard computer, they can adjust to any height, load, or passenger.

MacPherson Suspension

The Macpherson strut or suspension, invented by American automotive engineer Earle Macpherson, is one of the most extensively utilized suspension systems in automobiles.

The Macpherson strut, with its simple form and capacity to provide comfort, control, and minimal space consumption, finds frequent use.

The front suspension used a steering pivot to set it apart. A damper, a steering knuckle with two mounts, and a track control arm make up the suspension.

The knuckle’s top mount connects to the damper, while the lower one connects to the control arm, allowing the chassis and wheel to move in lockstep. The suspension can be adjusted to fit a wide range of cars and driving situations.

Trailing Arm Suspension

A steel arm with one end pivoted to the vehicle’s chassis and the other end to the rear axle, as well as a damper, makes up the trailing arm suspension.

A trailing suspension is typically found on the back of a vehicle but cannot be used on heavy-duty vehicles because the arm might bend and impair handling. The rear wheel of a motorcycle is the most common example of a trailing arm suspension.

Double Wishbone Suspension

These types of vehicle suspension systems are one of the most advanced suspensions ever created, as well as the most effective at smoothing out road bumps. Two A-shaped arms that resemble wishbones make up the double-wishbone suspension.

Only independent suspensions have this configuration, which provides more control and comfort even at high speeds and in tight corners.

The double-wishbone suspension and its modified variations are used in luxury cars, sports cars, and race cars because of their agility, stability, and comfort.

Related: List of best Tesla cars

FAQs

What are the 4 types of suspension systems?

- Independent suspension.

- Dependent suspension.

- MacPherson strut.

- Air suspension.

How do I know if my car suspension is bad?

If the car squats backward when accelerating, leans or rolls to the side when cornering, or dives forward when stopping, make sure to have it checked out by a mechanic.

Can you drive with bad suspension systems?

No. It is not recommended. A broken or collapsed spring may alter alignment angles and produce sagging and noise. You will still be able to drive, but it will be difficult to handle the car in an emergency, and the ride will be rough.

What is the function of the suspension?

The suspension helps with the vehicle’s handling and stopping, and it also keeps passengers comfortable by dampening road noise and bumps. When setting the suspension, it is important to strike a balance between handling and comfort. Each wheel can move independently in most modern suspensions.

What are the 3 main purposes of the suspension system?

The three primary functions or purposes of a car’s suspension system are as follows:

- Helps the tires maintain contact with the road.

- Absorbs driving shocks and vibrations.

- Controls the movement of the car.

What is the difference between a shock absorber and a suspension?

Shock absorbers are critical components of a suspension system and have a significant impact on the car’s overall handling and ride quality.

They are more accurately described as “dampers” because their function is to control the movement of the vehicle’s body and suspension over road imperfections, such as bumps and undulations.