You do realize that fuel is mixed in internal combustion engines? This mixing occurs in the carburetor. New automobiles now use fuel injection for the same process.

Nevertheless, most transportation, whether by land, sea, or sky, relies on the scientific secret of turning fuel into power. This occurs when it burns with air, causing a small explosion, although that may not be our primary goal here—perhaps it could be!

In this reading, we’ll explore what a carburetor is, its function, parts, types, and how it works. We’ll also learn its advantages and disadvantages.

Let’s begin!

Related: What Is A Fuel Injection System? Its Diagram and How It Works

What Is A Carburetor?

The design of a carburetor ensures it receives the precise air and fuel required for efficient combustion. The part has been the heart of a vehicle’s engine, ensuring smooth operation and improved horsepower.

The mechanical device known as a carburetor is able to precisely mix air, and even when it is cold, it starts or operates at a high speed.

A carburetor mixes the fuel from the gas tank, ensuring smooth operation and improved horsepower, and the spark plug ignites it. The air-fuel mixture must be precisely calibrated.

An efficiently functioning engine requires precise calibration of the carburetor. The engine “runs lean” when there is an insufficient fuel-to-air mixture, which can lead to the engine breaking down or not starting at all.

Functions of Carburetor

The carburetor in a car engine serves quite many functions. Here are the key functions of a carburetor:

- It regulates the air-fuel ratio and also mixes the fuels.

- Controls the engine speed.

- According to engine speed and load changes, carburetors increase or decrease the amount of mixture.

- It vaporizes the fuel and mixes the air into a homogeneous air-fuel mixture.

- It also helps to keep a certain amount of fuel in the float chamber all the time.

- It helps the fuel burn smoothly and properly without any problems.

A brief history of the invention of a carburetor is that carburetors have been around since the 19th century. Karl Benz, the founder of Mercedes, was a pioneer in the automobile industry and created it first. This, which has become an unforgettable history, was designed in 1888 and still, date carburetors are still in application.

Related: What Is An Automobile Engine? Its Diagram, Parts & How it works

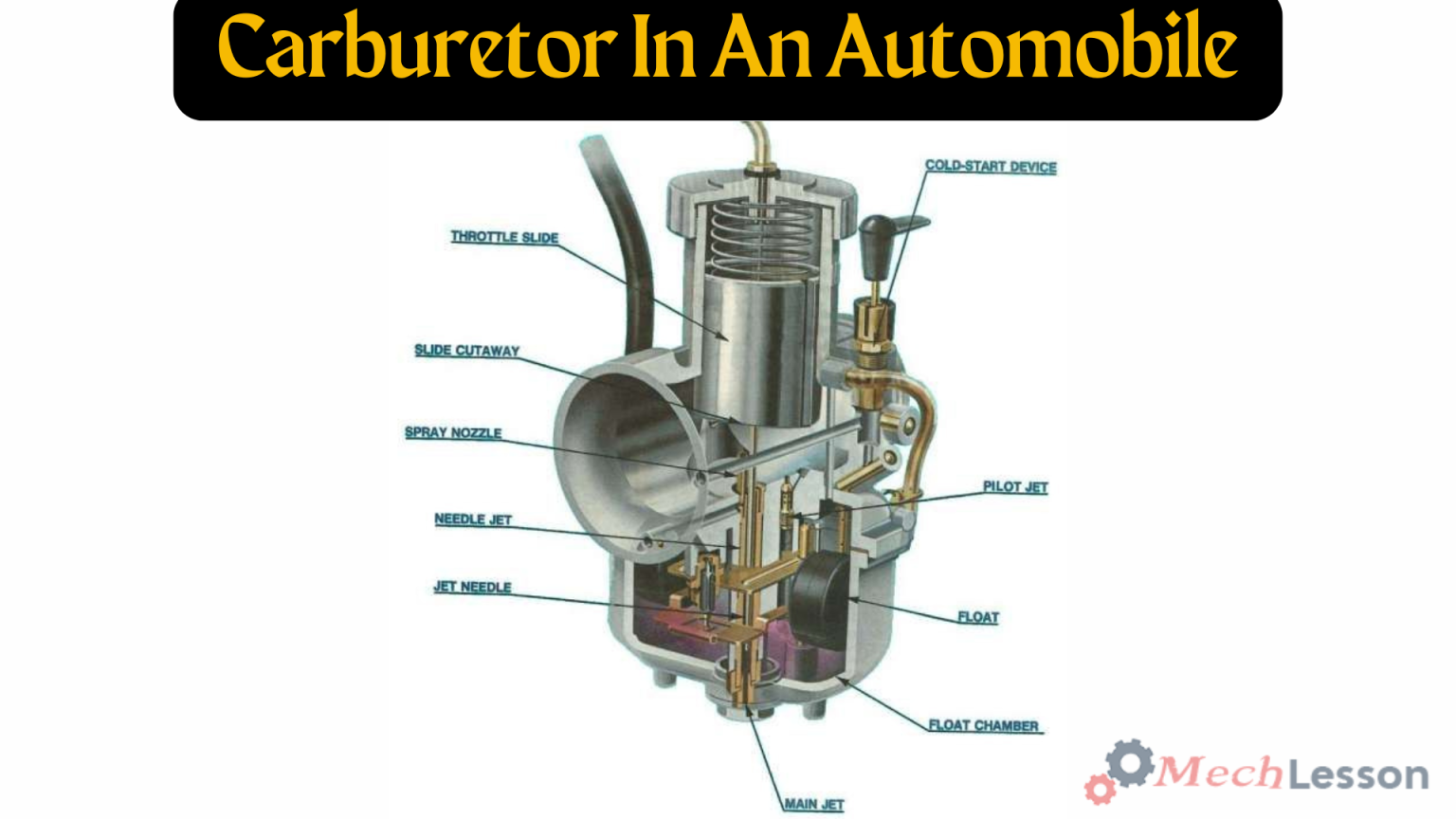

Diagram Of A Car Carburetor

Related: What is Fuel Induction Service And Its Cost?

Functional Parts of Carburetors

Here are the main parts of a carburetor and their functions:

Throttle Valve

The function of a throttle valve in a carburetor is to control the air/fuel mixture (charge) that enters the engine cylinder. Pressing the accelerator pedal opens this throttle valve.

Metering System

This part controls the flow of fuel into the nozzle, making it responsible for the exact mixture of air and fuel. It is made up of a fuel discharge nozzle and a metering orifice.

Idling System

The passage from the float chamber to the venturi tube is called an idling system. We refer to the passage from the float chamber to the venturi tube as an idling system that is open below 15% or during idling.

Strainer

A strainer is a device that filters the fuel before it enters the float chamber. A fine wire mesh constructs the strainer, removing dust and other suspended particles from the fuel. Nozzles get blocked if particles are not removed from the surface of the strainer.

Related: What is Throttle Position Sensor? Symptoms, & Working Principle

Venturi

A venturi is a cross-sectional hollow that gradually decreases to reduce the air pressure in the chamber. From it, fuel comes out of the fuel pipe to mix.

Choke Valve

A fine wire mesh constructs the strainer, removing dust and other suspended particles from the fuel. It purpose is to control the quantity of air inside the mixing chamber. Normally, the valve remains semi-open, but it operates when a rich mixture is necessary.

Float Chamber

Float chambers serve as fuel storage tanks, facilitating a continuous fuel supply. It features a floating valve that maintains the level of fuel in the float chamber. When the fuel level increases, the float moves upward, which closes and stops the fuel supply.

Mixing Chamber

The engine cylinder receives the air and fuel mixture from the mixing chamber.

Idle and Transfer Port

In the carburetor’s venturi, there are two nozzles or ports that help deliver fuel to the engine cylinder. In modern automobile engines, carburetors have additional parts to improve efficiency. These parts include:

Throttle Return Check

An engine operating at a high speed creates a high intake manifold vacuum when it is fully throttled. This vacuum will draw exhaust into the engine intake during valve/valve overlap. This will dilute the intake chart, leading to misfiring or stalling.

Related: Difference Between Fuel Injection And Carburetor

Automatic Mixture Control

A solenoid and spring control a plunger-shaped valve in a carburetor. It operates the separate jet in the float chamber. The solenoid is turned on, and the v/v is lifted to increase the amount of fuel supplied to the jet.

Anti-Dieseling Solenoid

Modern emission control engines typically operate at a higher temperature, leading to the formation of hot spots within the combustion chamber. These hot spots cause pre-ignition in the chamber. Modern engines design their carburetors with an anti-dieseling solenoid to prevent pre-ignition.

Types of Carburetors

Carburetors come in different designs, depending on the type of engine they are used in and their specific function. Here are the main types of carburetors:

Up-draft Carburetor

In the updraft type of carburetor, air enters through the bottom side and leaves through the top. This allows the air to flow upward. The float chamber provides the fuel, and the venturi creates the pressure difference between the two chambers.

Fuel comes out of the fuel pipe and mixes with the inlet air to form the fuel-air mixture. The fuel passes through the throttle valve, which is directly connected to the accelerator. This mixture then goes into the engine cylinder to perform combustion.

Down-draft Carburetor

The downdraft carburetor is the most common because of its advantages. It supplies air from the top portion of the mixing chamber. Some of its advantages include

- The gravity assists the flow of the mixture, making the engine pull better at lower speeds under load.

- The position of the carburetor is easily accessible.

- A higher value of the fuel pipe mixes with the inlet air to form such a part.

Though some disadvantages still occur, before that, allow me to explain why it is considered better than the up-draft type:

To prevent the limitation of downdraft carburetors revealed above, updraft is the only option. We place it at a level higher than the inlet manifold, where the air and mixture generally follow a downward course.

Even though the air velocity is low, the fuel moves into the cylinders by gravity rather than by air friction like the first type. Therefore, we can design the mixing tube and throat to be larger, leading to an increase in engine speed and the potential for high output.

Horizontal Carburetor

The horizontal carburetor, the third type, is identified when a downdraft carburetor is oriented horizontally. Its working principle is basic. An engine with such a part can achieve a higher value of volumetric efficiency. It is designed to mix the fuel before it enters the engine cylinder for combustion.

Related: The Difference Between 2-Stroke And 4-Stroke Engines

How A Carburetor Works

Therefore, we can design the mixing tube and throat to be larger, leading to an increase in engine speed and the potential for high output. creases.

The majority of the time, the engine’s fuel supply does not increase instantly when the driver presses the throttle pedal (except from the accelerator pump). Instead, the carburetor enhances the fuel intake mixture by increasing the airflow.

Carburetors differ greatly in terms of complexity and design. The most basic one is a horizontal fuel pipe connected to a massive vertical air pipe above the engine cylinders.

As air speeds through the narrow bend in the middle of the pipe, its pressure decreases. This kinked part is known as a venturi. The sucking effect of lowering air pressure draws in air through the side fuel pipe.

There are two swiveling carburetor valves above and below the venturi. The choke valve at the top is responsible for controlling airflow. When the engine receives a fuel-rich mixture, the venturi absorbs more fuel.

That helps when the engine is cold, starting slowly, and running slowly. The throttle valve is under the venturi.

Widening the throttle forces more air into the carburetor, which draws fuel from the side pipe. The engine produces more power and accelerates with more fuel and air.

This phenomenon is the reason a car accelerates when the throttle is opened; it works similarly to blowing on a campfire to increase the oxygen and speed up the burning process. In cars and motorcycles, the throttle is connected to the accelerator pedal or handlebar.

Carburetor Video

Related: What is Fuel Induction Service And Its Cost?

Advantages

Internal combustion engines have used carburetors for decades, especially in older vehicles and small engines like motorcycles and lawnmowers. Although modern engines mostly use fuel injection systems, carburetors still offer several advantages:

- Carburetor parts are less expensive when compared to those of the fuel injector.

- The components perfectly complete the air-fuel mixture.

- It has more power and precision than the air-fuel mixture.

- The engine component is not restricted by the amount of gas pumped fr the fuel tank. This is to say, the cylinders may pull more fuel through the carburetor, leading to greater power and a denser mixture in the chamber.

Disadvantages

While carburetors have certain advantages, they also come with several disadvantages, especially compared to modern fuel injection systems. Here are the main disadvantages of carburetors:

- The mixture supplied at a very low speed is weak, making the engine not perfectly ignite.

- Changes in atmospheric pressure can have an impact on the engine part.

- Compared to fuel injectors, fuel consumption is higher.

- Air emissions exceed those from fuel injectors.

- They require higher maintenance than fuel injectors.

Conclusion

The carburetor plays a crucial role in older internal combustion engines by mixing air and fuel in the right proportions for combustion. A well-functioning carburetor ensures smooth engine performance, better fuel efficiency, and easier starting.

Although modern vehicles use fuel injection systems, carburetors are still found in many classic cars, motorcycles, and small engines. Understanding how a carburetor works and maintaining it properly is key to keeping these engines running at their best.

FAQs on Carburetor

What is the main function of a carburetor?

A carburetor mixes the right amount of air and fuel for combustion in an internal combustion engine.

What are signs of a malfunctioning carburetor?

Symptoms include difficult starting, rough idling, poor fuel economy, black smoke from the exhaust, and engine stalling.

Can a carburetor be cleaned instead of replaced?

Indeed, dirt and clogged jets are the root cause of many carburetor issues. Cleaning it thoroughly can often restore normal performance.

How often should a carburetor be serviced?

Especially for vehicles not used daily, carburetors should undergo inspection and cleaning at least once a year.

What’s the difference between a carburetor and fuel injection?

A carburetor uses mechanical airflow to mix fuel and air, while fuel injection electronically controls the mixture for better efficiency and performance.

Why did modern cars move away from carburetors?

Fuel injection offers better fuel efficiency, lower emissions, and improved engine performance, meeting modern environmental and performance standards.