Have you been wanting to know what an engine truly is, or have you seen a machine and you wonder what truly powers it, and how it works? Are you a mechanical student, a technician, or just curious about what an engine is? Well, the engine is the secret behind what powers most machinery. Engines are a masterpiece of mechanical engineering that most people don’t even know about.

As a certified auto technician with over a decade of experience specializing in powertrain systems. I’ve examined countless car engines from classic muscle cars to the latest hybrid powertrains. In this comprehensive guide, we’ll go beyond the fundamental principles that make these machines work, backed by real-world examples and hand-on knowledge.

Let’s begin!

You should learn about Reciprocating Engine with this detailed guide!

What is An Engine?

An engine is a device that produces mechanical power by burning fuel. Internal combustion engines (ICE) power the majority of contemporary automobiles by burning gasoline and using the reaction to move mechanical components.

ICE engines operate the crankshaft and eventually move the wheels by burning gasoline or diesel fuel to propel pistons up and down. Engines are measured by technicians using the number of cylinders and their respective volumes.

An engine with eight cylinders arranged in a V shape that may displace 350 cubic inches is called a 350 V8. Although it’s not unusual to hear someone mention an electric car’s engine, EVs really have motors rather than engines. Electrical energy is transformed into motion by motors.

Automobile engines, like those that power automobiles, may run on a range of fuels, but in particular, gasoline and diesel. Natural gas and biofuels are two examples of alternative fuels, though.

Engines that generate macroscopic motion from heat are generally referred to as heat engines in thermodynamic terminology. In this instance, the engine’s fuel combustion, which drives pistons, produces the heat. Mechanical heat engines use a variety of thermodynamic methods to transform heat into work.

Perhaps the most well-known example of a mechanical heat engine is the internal combustion engine, where the heat from fuel combustion quickly pressurizes the combustion products in the combustion chamber, causing them to expand and power a piston that turns a crankshaft.

Newton’s third law of motion states that a reaction engine produces thrust by releasing reaction mass, in contrast to internal combustion engines.

In addition to heat engines, clockwork motors in wind-up toys employ elastic energy, pneumatic motors use compressed air, and electric motors transform electrical energy into mechanical motion.

Molecular motors, such as myosins in muscles, employ chemical energy to produce forces and, eventually, motion in biological systems. They are not heat motors, but rather chemical engines.

Air-breathing engines include chemical heat engines, such as rockets and deeply submerged submarines, that employ air as part of the fuel reaction.

Applications

- The engines convert energy from fuel to mechanical energy, creating motion.

- It can operate on various fuels, including gasoline and diesel for cars, biofuels, and natural gas.

- Its known as heat engines, they produce macrosopic motion from heat.

- Internal combustion engines are common in vehicles, boats, ships, airplanes, and trains.

- Fuel is ignited, and expanding gases move pistons in the engine.

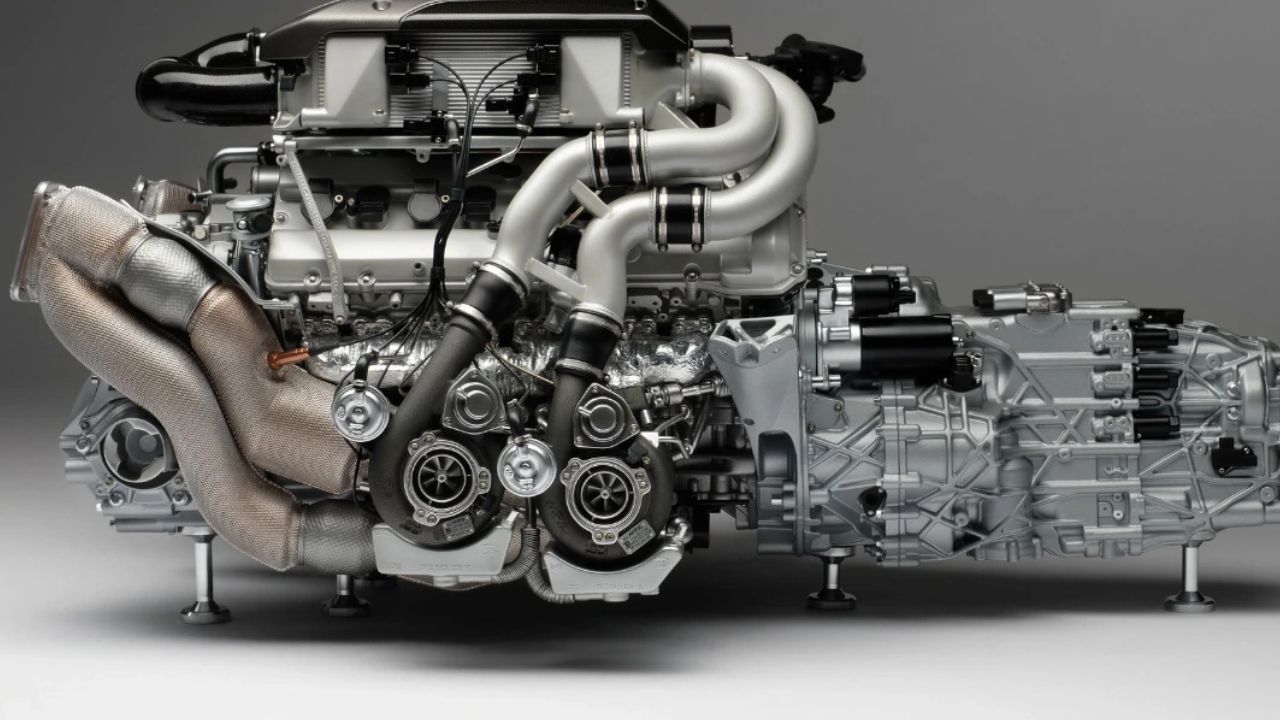

Diagram

You should also learn about Engine Mount with this detailed guide!

Types Of Engines

Below are the various types of Engine Including:

Pneumatic Engines:

Compressed air is used by pneumatic engines to produce power. They are frequently utilized in industrial settings for things like control systems and pneumatic equipment.

Compressing air with a compressor and storing it in a tank is how pneumatic engines operate. After being released through a valve, the compressed air presses against a rotor or piston to produce power. It is possible to use the power produced by the pneumatic engine to power a machine or tool.

Pneumatic engines are renowned for being straightforward, inexpensive, and simple to maintain. Because they don’t emit any hazardous fumes, they are also comparatively safe to use. They are constrained by the volume of air that can be kept in the tank, though, and are not as effective as certain other kinds of engines.

Wankel Engines:

Wankel engines transform fuel energy into motion using a rotary configuration. They bear the name of Felix Wankel, who invented them, and are renowned for their excellent power-to-weight ratio and small size.

A triangle rotor that revolves inside an oval-shaped chamber powers a Wankel engine. By pushing against the chamber’s walls, the expansion of a fuel-air combination powers the rotor and makes it spin. Power produced by the rotor’s rotation may be utilized to power a generator or an automobile.

Wankel engines are ideal for use in compact, portable applications since they are usually lighter and smaller than other engine types. They are also easy to repair because they are straightforward and have few moving components. They are not as popular as some other engine types, though, and they are less efficient.

Stirling Engines:

Stirling engines produce power by use of a sealed cylinder with a set volume. They are renowned for their low emissions and excellent efficiency, and they can be powered by a range of fuels, including solar energy.

You should learn about Engine Sputtering with this detailed guide!

In order to generate power, a working fluid—such as air or hydrogen—is heated and cooled inside a sealed cylinder in Stirling engines. An external heat source, such gasoline or sunlight, heats the working fluid, which subsequently expands as a result of the heating process.

Power is produced when the working fluid’s expansion presses up against a rotor or piston. The procedure is then repeated once the working fluid cools and contracts.

Because of their tiny size and weight, Stirling engines are frequently utilized in small-scale applications like refrigeration units and portable generators. Because of their great efficiency and minimal emissions, they are also utilized in some bigger applications, such ships and power plants.

Rocket Engines:

Rocket engines provide thrust and move a vehicle through the air or space by utilizing the action-reaction principle. They are found in spacecraft such as rockets and missiles.

Fuel and an oxidizer are burned in rocket engines to produce hot gasses that are released via a nozzle. High-speed expulsion of the hot gasses produces a force that pushes against the rocket and moves it forward. We call this force push.

Solid rocket engines, liquid rocket engines, and hybrid rocket engines are among the several varieties of rocket engines. In solid rocket engines, thrust is produced by burning a mixture of solid fuel and an oxidizer. Although they are straightforward and dependable, once they are lit, they are difficult to manage or extinguish.

Fuel and oxidizer are kept in separate tanks in liquid rocket engines before being fed into the engine and burnt to produce thrust. Although they need more upkeep and are more complicated, they are more controllable and adaptable since they are simple to turn on and off.

Solid fuel and a liquid or gaseous oxidizer are both used in hybrid rocket engines. They are less popular because of their poorer performance and dependability, although they do have some advantages over liquid and solid rocket engines.

Gas Turbine Engines:

Engines that employ the expansion of heated gases to produce power are known as gas turbine engines. They are frequently found in power plants, airplanes, and other devices that need a high power-to-weight ratio.

Compressed air is combined with fuel in gas turbine engines, which burns the mixture to create hot gasses. After that, a turbine expands the hot gasses, turning a shaft and producing electricity.

You should also learn aabout Steam Engine with this detailed guide!

A compressor, which pushes additional air into the engine, and a load, such a generator or an airplane propeller, are powered by the turbine’s energy. Simple cycle and mixed cycle are the two primary varieties of gas turbine engines.

The simplest kind of gas turbine engines are simple cycle ones, which merely employ a turbine to produce energy. Because of the energy wasted in the exhaust fumes, they have a lower overall efficiency even if they are effective at providing large power outputs.

More intricate, combined-cycle gas turbine engines produce power by utilizing two or more thermodynamic cycles. They usually include a heat recovery steam generator (HRSG), a gas turbine, and a steam turbine.

By expanding the hot gases created by burning fuel, the gas turbine produces electricity. Steam is then produced in the HRSG by heating water using the gas turbine’s exhaust gasses. To produce more power, the steam is further expanded by the steam turbine.

Because they can extract more energy from the fuel, combined cycle gas turbine engines are more efficient than simple cycle gas turbine engines.

Steam Engines:

Steam engines are those that provide mechanical power by using steam. They are presently largely utilized in power plants to generate energy, although they were historically widely employed in trains, ships, and other uses.

A piston or turbine is powered by the steam created when water is heated in a steam engine. A fuel, such coal or natural gas, is burned in a boiler to produce the steam.

Steam is created by heating the water with the heat from the burning fuel. After passing through a valve, the steam is sent to a turbine or cylinder, where it presses up against a rotor or piston to produce energy.

Turbine engines and reciprocating engines are the two primary kinds of steam engines. Whereas turbine engines utilize a rotor to transform the energy of steam into rotational motion, reciprocating engines employ a piston to transform the pressure of steam into linear motion.

Read about Car Engine Governor with this detailed guide!

Electric Engine:

Electric cars do not require the explosive combustion of combusted fuel to provide the energy required for mobility, in contrast to a normal internal combustion engine (ICE) vehicle that operates on gas.

Instead, they power the electric motor or motors attached to the wheels and move the vehicle forward using the electrical energy stored in their batteries. Therefore, even though they are currently more expensive initially, electric vehicles have fewer moving parts than gasoline-powered vehicles and often require less maintenance.

Electric motors are machines that produce mechanical power using electricity. They are frequently used to power a variety of devices, such as appliances, trains, cars, and elevators.

A coil of wire known as a rotor is used in electric motors to move through a magnetic field. A magnetic field is produced around the rotor when an electric current flows through the wire.

The rotor spins, producing mechanical power, as a result of the interaction between its magnetic field and the magnetic field of the stator, a stationary part of the motor. Electric motors come in several varieties, such as stepper motors, dc motors, and ac motors.

Whereas AC motors utilize alternating current (AC), DC motors use direct current (DC) to power the rotor. Stepper motors are an electric motor type that can be precisely regulated. They are frequently used in robotics and printers, among other applications that call for exact motions.

Hybrid Engine:

To put it simply, a hybrid uses a gasoline engine and at least one electric motor to propel the vehicle while regenerative braking helps the system recover energy. There are moments when the gas engine works alone, periods when the electric motor works alone, and times when both function together.

As a result, less gasoline is used and gas economy is decreased. In some situations, adding electrical power can even improve performance.

All of them are powered by a high-voltage battery (different from the standard 12-volt battery of the automobile), which is refilled by storing energy from braking that is often lost to the heat produced by the brakes in traditional cars. (The regenerative braking system does this.)

Additionally, hybrids charge and maintain their batteries using the gas engine. Different hybrid designs are used by automakers to achieve a variety of goals, from optimizing fuel efficiency to minimizing vehicle expenses.

Internal Combustion Engine:

An internal combustion engine is an engine where fuel is burned in a small area known as the combustion chamber. When a fuel and an oxidizer react exothermically, high-temperature, high-pressure gases are created that have the ability to expand.

An internal combustion engine’s distinguishing feature is that its expanding hot gases do beneficial work by directly causing movement, such as pushing and rotating the engine’s rotors and pistons. Currently, two kinds of internal combustion engines are produced: compression-ignition diesel engines and spark-ignition gasoline engines.

The majority of these engines are four-stroke, which means that a cycle requires four piston strokes. Intake, compression, combustion and power stroke, and exhaust are the four separate operations that make up the cycle.

The way fuel is delivered and ignited in compression-ignition diesel engines and spark-ignition gasoline engines is different. During the intake phase of a gasoline engine, fuel and air are combined before being drawn into the cylinder. Combustion results from the spark igniting the fuel-air combination after the piston has compressed it.

During the power stroke, the piston is pushed by the combustion gasses’ expansion. The only fuel that is pulled into a diesel engine and compressed is air. The hot compressed air is then ignited by diesel engines spraying the gasoline in an appropriate, measured volume.

Read about Engine Blow-by with this detailed guide!

External Combustion Engine:

Fuel and exhaust products are separated in external combustion engines (EC engines), which heat the engine’s working fluid via a heat exchanger or the engine wall while burning the fuel in a chamber. This includes the steam engine, the forerunner of the industrial revolution.

EC engines and their IC equivalents function somewhat similarly in that they both need heat, which is produced by burning materials. But there are significant distinctions as well. The fluids used in EC engines go through phase shifting or thermal dilation contraction, but their chemical makeup doesn’t change.

The fluid used in internal combustion engines is almost always a liquid fuel and air mixture that burns (changes its chemical composition). The fluid can be gaseous (as in the Stirling engine), liquid (as in the organic Rankine cycle engine), or undergoing a phase change (as in the steam engine).

Lastly, the engines have the option of constantly using the same fluid (closed-cycle engines) or draining it after use, like internal combustion engines do (open-cycle engines).

How do Engines work?

The engine itself is where the gasoline is ignited and burned in an internal combustion engine (ICE). The energy from the combustion is then partially transformed into work by the engine.

A stationary cylinder and a moving piston make up the engine. The crankshaft revolves as the piston is pushed by the expanding combustion gasses. This motion ultimately powers the vehicle’s wheels via a powertrain gear system.

Currently, internal combustion engines come in two varieties: compression ignition diesel engines and spark ignition gasoline engines. The majority of them are four-stroke engines, which require four piston strokes to finish a cycle.

Intake, compression, combustion and power stroke, and exhaust are the four separate operations that make up the cycle.The way fuel is supplied and ignited in compression-ignition diesel engines and spark-ignition gasoline engines is different.

During the intake phase of a spark ignition engine, fuel and air are combined before being inducted into the cylinder. Combustion results from the spark igniting the fuel-air combination after the piston has compressed it. During the power stroke, the piston is pushed by the combustion gasses’ expansion.

All that happens in a diesel engine is the induction and compression of air. After that, diesel engines ignite the fuel by spraying it into the heated compressed air at a precise, appropriate pace.

You watch the video below to learn more about engines:

Read about Engine Knocking with this detailed guide!

FAQs

Which car has the strongest engine?

- The 2,300 horsepower Koenigsegg Gemera.

- 1,984 horsepower is the Aspark Owl.

- 1,972 horsepower is the Lotus Evija.

- 1,900 horsepower is the Pininfarina Battista size.

- 1,817 horsepower is the Hennessey Venom F5.

- 1,813 horsepower Rimac Nevera.

- 1,775 horsepower Bugatti Tourbillon.

- The CC850 Koenigsegg has 1,385 horsepower.

How much does an engine cost?

Even changing the engine on your own will probably cost $2,000 or more utilizing the most economical choices, and hiring a professional to handle the repair may cost anywhere from $3,000 to $8,000 or even more.

What is the function of the engine?

An engine is a device that transforms fuel energy into mechanical energy, which generates motion. There are many various fuels that engines, such those used in automobiles, may run on, but the most common ones are gasoline and diesel.

What is a motor vs engine?

A “motor” is a mechanism that provides motive power for a vehicle or other equipment having moving parts, according to the Oxford English Dictionary. Likewise, it informs us that an engine is a device that transforms power into motion and has moving parts. “Now, we use the terms interchangeably,” Fuller explains.

What is an engine on a car?

Power is transferred from the engine to the gearbox and subsequently to the wheels. The internal combustion system can save a lot of weight since it doesn’t require motors or a controller, but the engine usually has to go through a more difficult procedure to reach the wheels than electric motors do.