In metalworking, forging operations are carried out using different methods, depending on the shape, size, and production requirements. The forging principle is quite straightforward.

Forging principle applies across all its types of operation — applying compressive forces to shape metal — what makes these processes differ is the way forces are applied and controlled. For example, a forging method like open-die forging allows for a gradual shaping of large or simple components, while closed-die forging, are designed for high-precision parts with complex geometries.

In this reading, we’ll go over the different types of forging operations.

Let’s get into it!

Types of Forging Operations

The types of forging operations are upsetting, drawing, bending, fullering, edging, cutting, swagging, forge welding, punching, flattening, setting down, and jumping.

1. Upsetting:

We perform these forging operations to expand the length of the workpiece by increasing its cross-sectional area. The force is applied in a parallel direction to the long axis. A good example of an upsetting operation is a bolt head.

This procedure was used to expand the stock’s cross-sectional area over the length extension. To achieve the length, for instance, in the development of the bolt head, the offsetting force is applied in a direction parallel to the long axis.

2. Drawing:

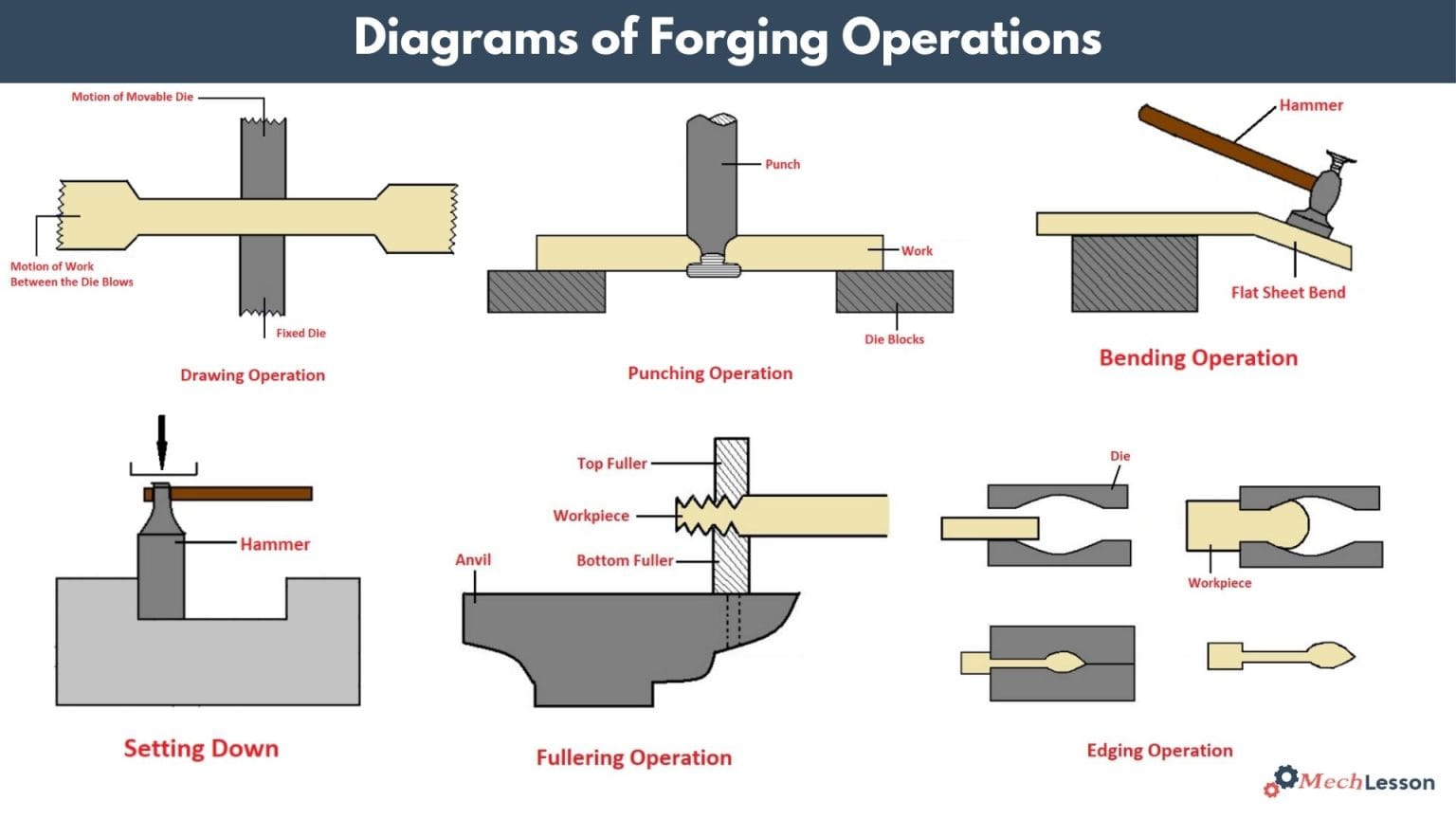

By pulling and stretching in the cross-sectional area, these types of forging operations lengthen the metal. We apply the force perpendicular to the length axis. To extend a metal’s length is called Drawing out.

The image below illustrates this process. The hammer strikes the beak of the anvil after heating the metal to a temperature between two and one. Fuller is also used for this purpose.

3. Bending:

“Bending” is the act of turning or bending a piece of metal into a round or angular shape. We use this process to create round rings and other shapes. Bending operation is the most common and easiest forging. It is done to give a turn shape to a metal rod or plate.

4. Fullering:

Fullering is a forging operation done by keeping the bottom fuller in an angle hole with the heated metal placed on it; the top fuller is then placed above the metal, and force is applied through the top fuller using a sledgehammer.

Related: 16 Different Types of Forging Tools, Their Uses &; Diagram

5. Edging:

This forging operation is carried out by striking or forcing the metal plate into the desired shape. The workpiece is forced between two die edges.

6. Cutting:

Cutting is a forging operation that is carried out when metal needs to be cut apart. The operation is done when the metal is in a red-hot condition using a chisel and hammer.

It is the process of reducing the length of long metal rods and plates; it can be done with cold or hot metals and requires the use of a chisel with a cutting angle. Metals thicker than 20 mm should only be cut after being heated.

7. Swaging:

This forging operation is done to reduce the finished work into the desired size and shape, usually either round or hexagonal. Bottom swage is used for small jobs, while large jobs are performed by swage block.

Related: 9 Different Types of Forging Defects, Causes and Their Remedies

8. Forge welding:

These types of forging operations are performed when two pieces of metal need to be joined to increase the length. The operation is done by pressing or hammering the workpiece edge by edge while still adhered.

In this method, the metal pieces are heated at the proper temperature in a furnace and joined together by pressure or blows. The ends of the metal pieces are scarfed during forge welding by jumping.

9. Punching:

This forging operation is done to produce holes in the workpiece. The workpiece is placed on a hollow cylindrical die, placing the punch to the area where a hole is required.

In this procedure, a punch is used to create a hole in heated metal. The work is first placed on the punch hole of the anvil, nut, etc., for punching, after which the hole is either made with a punch or holes that have already been made by drift are widened.

10. Flattening and setting down:

Flattenning and setting down are done to obtain a smooth surface with the use of a flatter or set hammer. This operation is done after fullering leaves a corrugated surface on the metal or after the workpiece is forged into shape with a hammer.

11. Jumping:

Jumping or upsetting refers to the process of heating metal in order to shorten and thicken it. The length of the metal can be almost cut in half by hopping. One can jump in three different ways: head jumping, center jumping, and full jumping.

Conclusion

Each and every forging operation have their advantages. The forging operation you use depends on the size, shape or even the mechanical requirement of the component you’re working with. Every method has its specific applications as seen from open-die to closed-die forging, and roll forging.