Many issues may arise in your electrical component if a ground strap is not working properly. The majority of electrical equipment must be grounded for safety reasons. As an electrical student, technician, or DIY worker, it is important for you to know what a grounding strap is, its purpose, and how it works. Well, with over a decade as an engineer, I will explain everything you need to know about this electrical component, including its diagram and applications.

Let’s begin!

Learn about Car Electrical System with this detailed guide!

What is a Ground Strap?

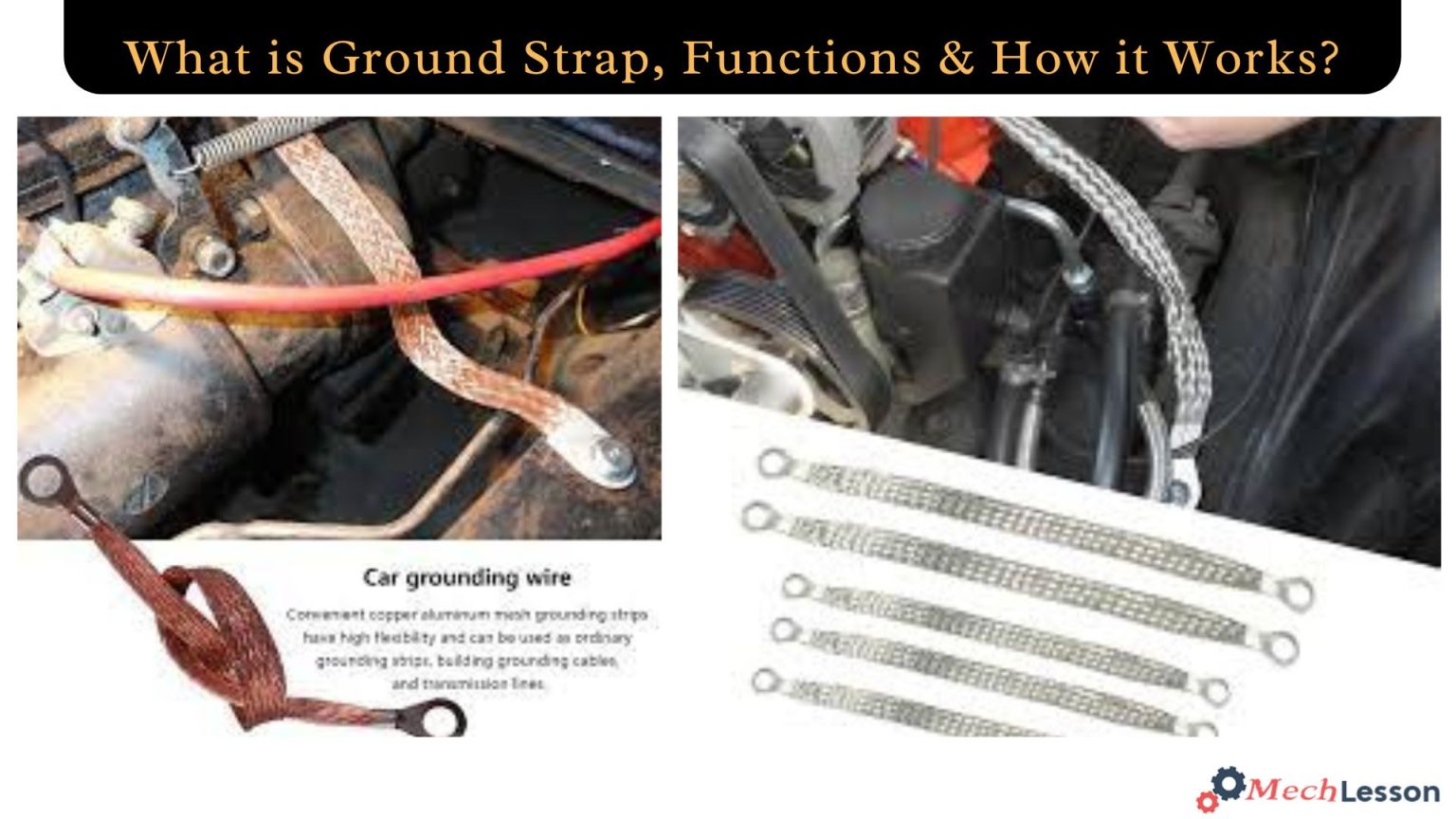

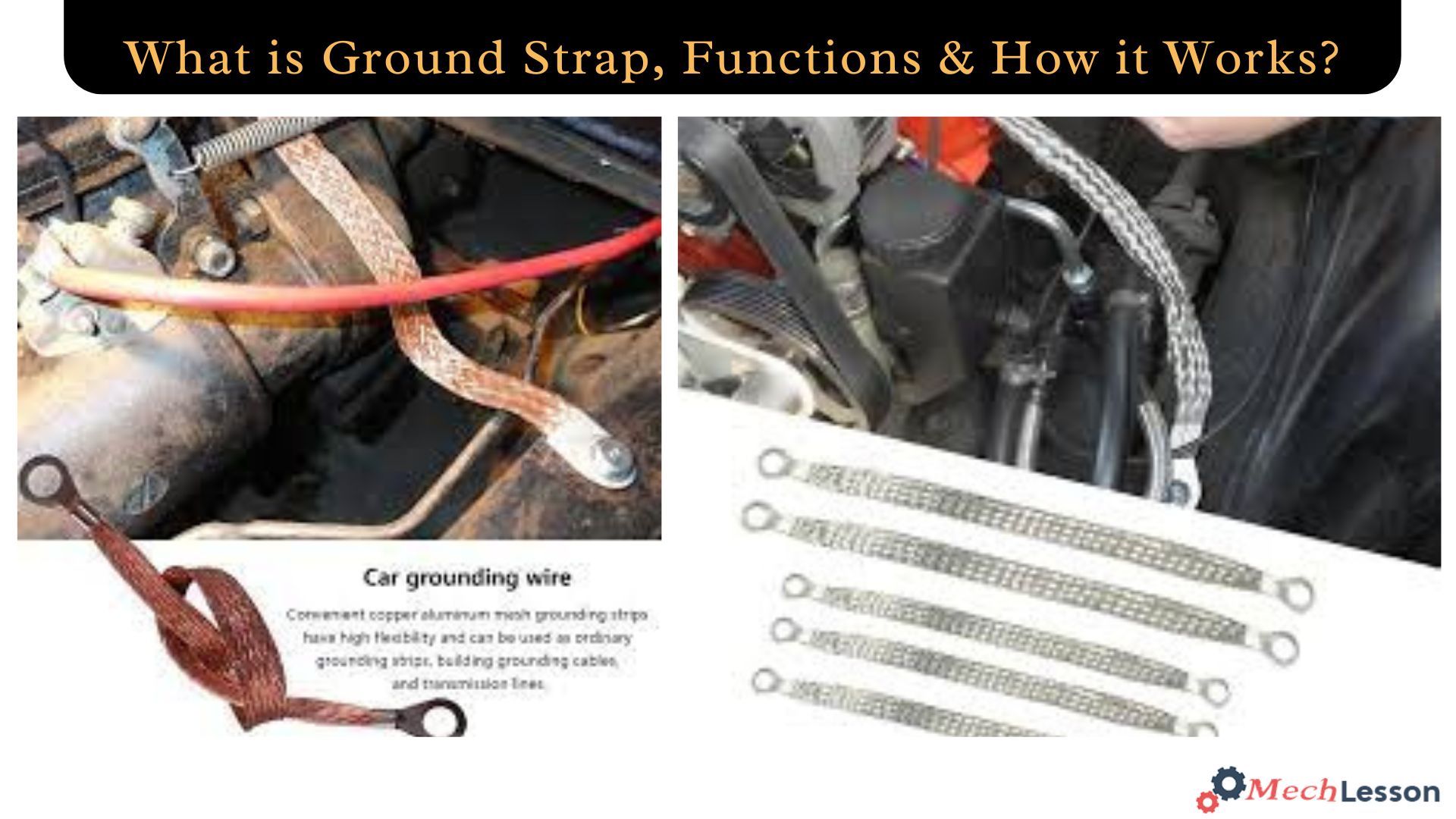

A ground strap is a flexible, conductive strap, typically composed of braided copper, that establishes a low-resistance electrical connection between two places. It is called a ground strap, grounding strap, or earthing braid. It is used in a variety of applications, such as automobiles, machinery, and industrial equipment; it is essential for safety and appropriate electrical system operation.

A ground strap is made of conductive materials like copper or carbon. The grounding strap is frequently used in the manufacture and repair of electronic devices because static electricity can harm delicate electronic components.

By discharging any static energy that has accumulated on their body while wearing a grounding strap, the individual can stop it from spreading to the electrical device they are working on.

In fields like oil and gas where combustible vapors and fumes are present, grounding straps are also utilized. Grounding straps are employed in these conditions to avoid sparks that could ignite the gases, lowering the possibility of explosions and fires. In general, grounding straps are a vital safety precaution to avoid the buildup of static electricity and lessen the possibility of electrical hazards.

You should also learn about Electric Vehicles vs Gasoline Vehicles with this detailed guide!

Applications

Just as clearly explained, ground straps are essential components in various industries, including automotive, industrial equipment, electronic devices, and aircraft. They connect engine blocks to chassis or negative battery terminals, ensuring proper electrical system operation.

They are used in machinery, generators, transformers, and electronics to prevent static buildup and protect components. Ground straps are typically made of braided copper, which offers flexibility and good electrical conductivity.

They can also be tinned or nickel-plated for corrosion resistance or high temperatures. Key features of ground straps include flexibility, low resistance, durability, and safety. They are crucial for maintaining electrical safety and ensuring the proper functioning of various systems.

By providing electricity a return path, grounding creates a complete circuit. The positive terminal of your car’s battery will allow electricity to flow to all of its electrical parts. It will then proceed to the ground connector.

In the case of a power surge or short circuit, the ground strap will shield the electrical parts of your car from harm. The ground strap will disperse excess electrical current if it is flowing to or from an electrical component. Normally, electrical parts are connected to the engine, which is subsequently linked to the chassis or the negative battery terminal.

Importance of ground straps

Ground straps are essential for grounding electrical components, providing a reliable path for currents, and preventing shocks and static discharge. They are flexible and durable, making them suitable for connecting components that may move or vibrate. Ground straps also provide safety by minimizing the risk of injury or damage from electrical faults or static discharge. Let me further explain the several reasons why grinding straps are important.

- Preventing electrical hazards: Ground straps offer a secure and reliable technique to stop the accumulation of static electricity, which can result in electrical hazards like shocks, fires, and explosions.

- Protecting electronic equipment: Static electricity can harm delicate electronic components during the manufacture and repair of electronic equipment. The user can discharge any static energy that has accumulated on their body while wearing a grounding strap, preventing it from moving to the electronic equipment and potentially damaging it.

- Ensuring safety at work: Grounding straps are used in industrial settings where combustible gases and vapors are present to avoid sparks that could ignite the gases, lowering the risk of explosions and fires. This promotes worker safety at the workplace.

- Meeting regulatory requirements: Regulations and standards from organizations like the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA) frequently call for the use of ground straps (NFPA). Companies can ensure compliance with these regulations and stay out of trouble by utilizing grounding straps.

- In general, grounding straps are a crucial safety measure that can help avoid electrical risks, safeguard electronic equipment, guarantee workplace safety, and adhere to legal requirements.

You should also learn about Junction Box with this detailed guide!

How Does a Ground Strap Work?

The working principle of a ground strap is pretty straightforward:

It works by creating a conductor between a person or object and the Earth, which serves as an electrical ground. The ground strap enables static electricity to safely flow from an object or person to the Earth, preventing a buildup of static electricity that could result in electrical risks or harm to electronic devices.

For instance, in electronic manufacturing and repair, a grounding strap is often attached to the wearer’s wrist or ankle, with the other end connected to an electrical ground point like a grounding wire or a grounded metal surface.

An automobile’s engine is grounded via the ground strap, which connects to the chassis or the negative battery terminal. A given vehicle’s chassis is grounded, as well as its negative battery terminal. Automotive engines are frequently connected with one of these areas through a ribbon-like ground strap to provide an additional path for electricity.

Any static energy that has accumulated on the person’s body is securely discharged through the grounding strap when they touch a delicate electronic component, protecting the component from damage.

Similar to this, grounding straps are utilized in industrial environments like oil and gas to stop sparks from igniting dangerous vapors and gases. Any static energy that builds up on the machinery or equipment is securely discharged, lowering the risk of sparks and hazardous explosions or fires, by connecting the machinery or equipment to an electrical ground using a grounding strap.

Diagram

You should learn about a Starter Motor with this detailed guide!

Types of Ground/Grounding Straps

To prevent electrostatic discharge (ESD) and assure electrical safety, an electrical component or piece of equipment is connected to a grounding point using a grounding strap. Grounding straps come in a variety of types, including

- Wrist straps: Wrist straps are the most commonly used type of grounding strap. They are worn around the wrist and connect to a grounding point, such as an ESD mat or grounded workbench.

- Heel straps: Heel straps are similar to wrist straps, but they are worn around the heel of the foot instead of the wrist. They are often used in conjunction with ESD flooring to provide a complete grounding system.

- Toe straps: Toe straps are another type of grounding strap that is worn around the toes. They are less commonly used than wrist and heel straps.

- Grounding cords: Grounding cords are used to connect equipment to a grounding point. They are typically used in situations where a wrist strap or heel strap is not practical or necessary.

- Grounding plates: Grounding plates are metal plates that are connected to a grounding point. They are often used in situations where a large surface area needs to be grounded, such as with a large piece of equipment or machinery.

- Grounding reels: Grounding reels are retractable cords that are used to connect equipment to a grounding point. They are often used in situations where mobility is important, such as with handheld tools or equipment.

Types of grounding straps based on their construction and materials, which include

- Braided ground straps: These are made from woven strands of metal, usually copper or tinned copper, and are flexible and durable.

- Mesh or grip ground straps: These are made from a knitted mesh of metal wire, usually stainless steel or nickel-plated materials. They have a non-slip grip and are often used in applications where there is a risk of slippage.

- Strip or sheet ground straps: These are made from a flat strip or sheet of metal, usually copper or stainless steel. They are less flexible than braided or mesh straps but are often used in applications where a low profile is required.

- Solid wire ground straps: These are made from a single, solid wire of metal, usually copper or silver-plated materials. They are the least flexible but are often used in applications where high conductivity is required.

Note: The selection of a grounding strap’s material will be influenced by properties including conductivity, robustness, and corrosion resistance, as well as other environmental conditions.

High-conductivity materials like copper and tin-plated copper are frequently utilized, whereas stainless steel and nickel-plated materials offer higher corrosion resistance. In applications where extremely high conductivity is required, silver-plated materials may be used.

You should learn about The Best Portable Jump Starter For Car with this detailed guide!

What are the Electrical Devices that are Commonly Grounded in a Vehicle?

Here are the most common electrical devices often grounded in a vehicle:

What are the symptoms of a bad grounding strap?

Here are the most common signs and symptoms of a bad grounding strap:

Lights Flickering:

The electrical circuit will encounter resistance when trying to supply electricity to the headlights in front of your vehicle if your ground strap is worn out or damaged. You’ll probably notice your headlights frequently flickering or dimming as a result.

As long as your ground strap continues to be defective, this will not be a one-time occurrence. Your ground strap could occasionally be just a little bit too loose, in which case you will need to tighten it firmly. If it is harmed or worn out, you will need to replace it entirely.

Car Won’t Start:

Your car might not start for several reasons. But if you have already encountered the first three of these signs, it is safe to predict that you will soon experience trouble starting your car. When you try to start your car with a broken ground strap, you undoubtedly hear a lot of tapping noises. This is produced by the starter solenoid as it constantly opens and closes.

That occurs since, once more, the cable that connects to the negative terminal of your battery is not receiving adequate voltage.

Low Voltage:

You can run a voltage test on your battery if there still seems to be electricity in your car, but it is a little bit weaker than usual. You can gauge the voltage coming from your battery connections using a digital multimeter.

A measurement of 12.6 volts would be considered normal. But if your result is below 11.5 volts, you most likely have a grounding problem. At that point, you ought to glance at the ground cable to begin your troubleshooting.

You should learn about The 5 Possible Reasons Why Your Jumper Cables Melted with this detailed guide!

The Ground Strap Appears to be Damaged

Visually inspecting your ground strap is the best way to check that it is damaged. It is safe to presume that you need to replace the ground strap if it immediately looks to be worn out or damaged. This is particularly true if you also experience the other symptoms listed above. At this point, your only option is to swap out the cable for a new one.

Rodents are one cause of damage that you probably haven’t thought about if you keep your automobile outside for an extended period. Mice, and occasionally even squirrels, adore the secure environment of an engine compartment and won’t think twice about constructing a nest there. You might wish to think about purchasing an interior mouse repellent.

Dead Battery

Don’t assume the battery in your car is faulty if it seems like it won’t take a charge. The charging system in your car depends on a solid footing. The battery cannot be charged if the ground wire is damaged. Of course, problems with the alternator or the cable that links the alternator to the battery could also be to blame for a dead battery. However, if these components are in fine shape and your battery is still dead, the issue is probably with a defective or slack ground strap.

How much does grounding strap replacement cost?

Depending on the automobile model and labor expenses, replacing a ground strap typically costs between $20 and $80. Costs for labor and a ground strap range from $10 to $50. Fortunately, ground straps are frequently inexpensive and simple to replace.

Self-replacement is simple, but hiring someone else will cost you between $10 and $30. Make sure you have the radio code before you begin the replacement since when you change the ground strap, your car will lose all memory functions, including the radio code.

Conclusion

The ground strap may seem like a minor component, but it plays a critical role in a vehicle’s electrical system by ensuring proper grounding between the engine, chassis, and battery. It helps prevent electrical issues, protects sensitive electronics, and ensures stable voltage flow for reliable engine performance and sensor operation.

A damaged or corroded ground strap can lead to hard starting, flickering lights, or electronic malfunctions. Regular inspection and timely replacement are essential to maintaining a healthy and efficient electrical system. In short, the ground strap is a small but essential link in your vehicle’s overall reliability.

You should also learn about The 6 Reasons Why Your Car Won’t start in Cold Weather with this detailed guide!

FAQs

What is a ground strap?

The ground strap is a part that joins the engine block to the chassis or negative battery terminal, completing the electrical circuit and enabling the operation of various vehicle systems as a result.

Why do you use a ground strap?

In the case of a power surge or short circuit, the ground strap will shield the electrical parts of your car from harm. The ground strap will disperse any excess voltage that is moving to or from an electrical component.

How do grounding straps work?

To make wrist straps visible to others, they are often fashioned in a bright color. To create a grounding path, they are made to be worn near the skin. They immediately discharge the static that is building up on the body to the ground.

Why a ground strap instead of a wire?

A grounding wire has a metal connector on each end, just like a grounding strap does. A ground wire, on the other hand, is made up of just one strand and is not braided. As a result, grounding straps rather than grounding wires are used in heavier-duty applications.

Will a car run without a ground strap?

Without the strap, there is a significant risk that your car will malfunction or experience a short circuit. The ground strap also makes sure that the battery runs at a constant voltage. A lack of ground straps increases the likelihood of a short circuit.

Where do you connect ground straps?

You can attach a wrist strap to several locations to get grounded. Wrist straps may be fastened to a ground line by way of an electrical outlet or clipped onto the free-standing ground (like a metal table on a stone floor).

What happens if a car battery is not grounded?

Without solid grounds, the flow of electrons from negative to positive won’t be sufficient to adequately power the circuit’s gadgets. You might have TOO MANY electrons on an object like the engine block if the grounds are poor, which might cause parts like the alternator to burn out.

What is an electrical ground strap?

By directing the electric current to a secure ground, grounding straps serve as anti-static devices that shield people and electronic equipment from electrostatic discharges (ESD).

How do you test a ground strap?

How to Use a Multimeter to Test a Ground Wire

• On the multimeter, choose the Ohm setting.

• Connect a multimeter’s lead to the car’s metal chassis.

• The ground wire’s end, which is not connected to anything, should be touched with the multimeter’s other lead.

• The ground wire is in good condition if the multimeter reads zero Ohms.

What are the different types of ground straps?

Ground straps come in four different types: braided, mesh or grip, strip or sheet; and solid wire. There are several different material types used to make the four different types of grounding straps, including aluminum, copper, tinned copper, stainless steel, nickel-plated materials, and silver-plated materials.