What is Plasma Arc Welding (PAW)?

This type of arc welding process, similar to tungsten inert gas welding (TIG), utilizes a non-consumable electrode. It creates an arc between the electrode and the workpiece.

Plasma arc welding (PAW) creates a strong bond by using heat from a narrow arc formed between a tungsten electrode and a nozzle, which is called a non-transferred arc. It can also happen between a tungsten or alloy tungsten electrode and the workpiece, known as a transferred arc. It can also be between a tungsten/alloy tungsten electrode and the workpiece, which is a transferred arc.

This process can use two inert gases; one forms the arc plasma and the other creates shields for it. Similar to TIG welding, the addition of filler metal is optional.

PAW welding is considered an advancement over TIG welding. in TIG welding, the open arc is shielded by argon and helium, but in plasma, a special torch uses a nozzle to separately push the arc and shield gas to the torch.

The arc is constricted and pushed by a water-cooled, small-diameter nozzle. By squeezing the arc, it increases its temperature, pressure, and intense heat, helping to improve its stability.

As previously mentioned, two gas flows, laminar and turbulent, form PAW arcs. The luminal flows at low pressure and low flow of plasma gas, which is employed to ensure that the molten metal is not blown out of the weld zone.

On the other hand, the turbulent flow operates under high pressure and produces high levels of plasma gas. These gases are argon, helium, or hydrogen, or they could be a mixture of them.

Applications

Traditional applications of micro-plasma welding include welding wire and mesh sections, as well as thin sheets with a minimum thickness of 0.1mm. The marine and aerospace industries use it. We use plasma arc welding to weld stainless steel and titanium pipes and tubes.

This welding process is an excellent choice for repairing tools and dies. We also use this welding process to coat and weld turbine blades. Finally, the electronic industries widely use plasma arc welding.

In essence, TIG welding is a traditional process used in the medical industry, but plasma welding (PAW) is a more efficient method for manufacturing steel tubes.

PAW offers high-speed welding with great metal penetration, making it ideal for delicate materials sensitive to environmental factors. Its low current mode allows for small metal component welding, making it ideal for the medical industry, where precise components are required for effective operation.

Related: How Does Tungsten Inert Gas (TIG) Welding Works?

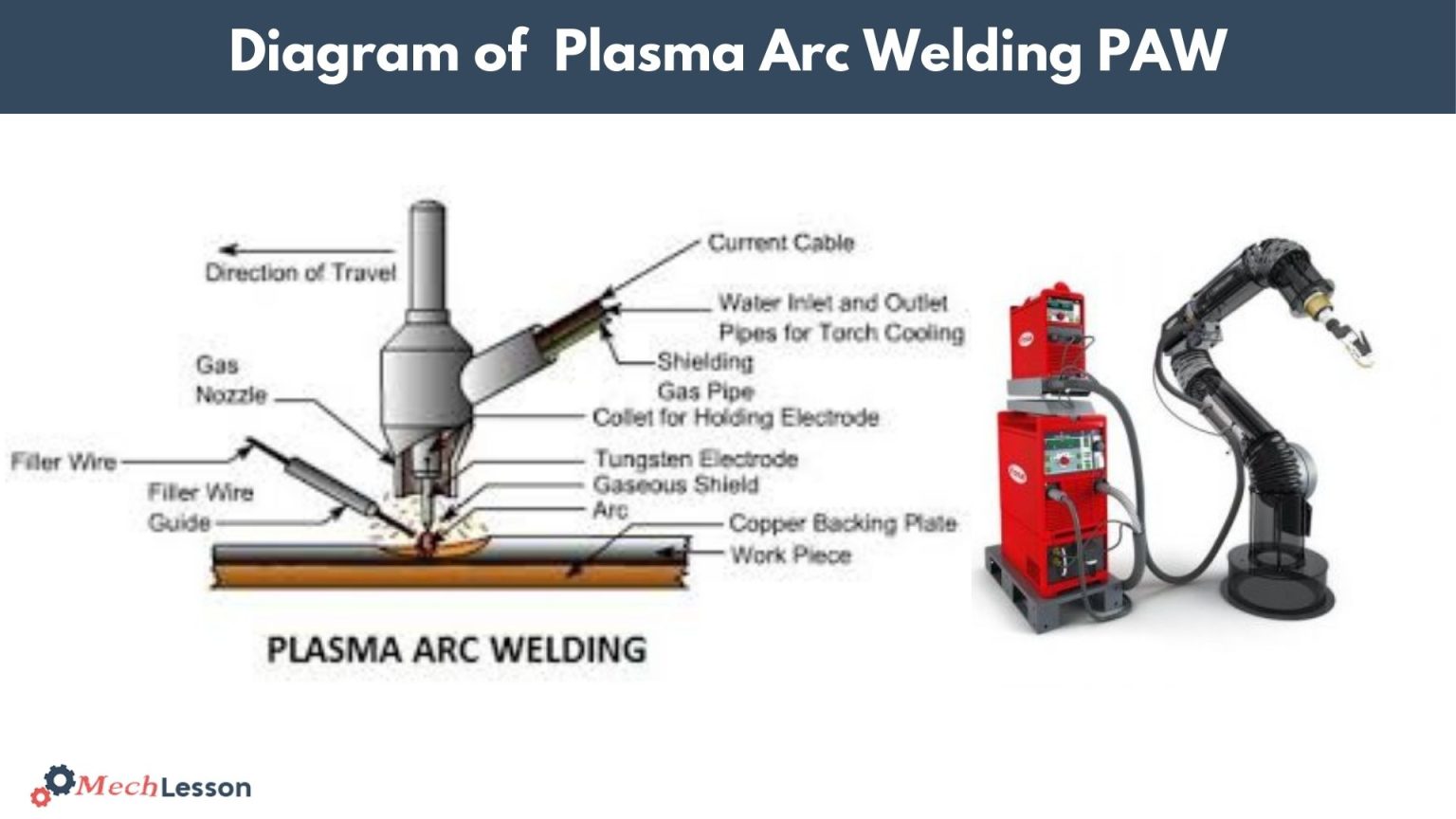

Components of Plasma Arc Welding

The major parts of a PAW machine include a power supply, shielding gas, plasma torch, voltage current, current and gas decay control, fixture, voltage current, and high-frequency generator. Here is a quick explanation of the machine parts.

The plasma welding process involves a high-power DC supply to generate an electric spark between the tungsten electrode and welding plates, similar to TIG welding. The plasma welding torch is crucial in this process, as it is water-cooled and can weld at a low 2 amps. The power source consists of a transformer, rectifier, and control console.

The plasma welding torch is water-cooled, providing a water jacket outside the torch. A water recirculator cools the torch with the continuous flow of water outside it. We use the tungsten electrode, which can withstand high temperatures.

This process uses two inert gases, helium and argon, along with hydrogen to maintain low pressure and prevent turbulence. Plasma gas, an ionized hot gas composed of nearly the same number of electrons and ions, is the main energy source for this welding.

We use torch accessories to enhance the performance of the welding torch. If we use filler material, we feed it directly into the weld zone. The plasma welding process requires a high-power DC supply, a tungsten electrode, shielding gases, and voltage current. The plasma gas is an ionized hot gas with sufficient energy to free electrons from molecules, atoms, and electrons to synchronize.

Diagram of Plasma Arc Welding Machine

Related: What Is Orbital Welding? Its Diagram, Types, And Application

How Does Plasma Arc Welding (PAW) Work?

Plasma arc welding involves striking an arc between a non-consumable tungsten electrode and the workpiece. The nozzle’s unique design allows the arc plasma to exit the torch separated from the shielding gas envelope.

The narrow opening of the nozzle increases the flow rate of plasma gas, allowing deeper penetration. The complexity of the plasma welding torch sets it apart from gas tungsten arc welding. Plasma welding torches operate at high temperatures, making it necessary to always be water-cooled.

Modern plasma welding guns are designed for automatic welding. Common defects associated with plasma welding include tungsten inclusions and undercutting. Tungsten inclusions happen when the welding current is too high for the electrode, and undercuts often occur in keyhole mode PAW welding but can be prevented by using activated fluxes.

Operating Modes of Plasma Arc Welding

Microplasma welding is a versatile welding technique that utilizes three operating modes: Microplasma (0.1-15A), Medium current (15-200A), and Keyhole mode (over 100A). Microplasma welding allows for low currents and stable arcs up to 20mm, making it ideal for joining thin sheets up to 0.1mm thick.

Medium current offers better penetration and protection but requires maintenance and is bulkier than TIG welding. Keyhole mode, on the other hand, uses a powerful plasma beam to engage in high-current welding, allowing deep penetration and consistent weld pool creation from molten metal.

Mechanized welding, positional welding, and pipe welding commonly utilize this mode, which is ideal for welding thicker materials at high speeds. Typically, we add filler material to ensure satisfactory welds.

Difference Between PAW and TIG

Plasma welding is a method that uses a welding torch to create a plasma jet with high heat concentration, offering deeper penetration. It differs from TIG welding, which uses a tungsten electrode to strike an arc between the torch and the workpiece.

Plasma welding offers greater precision and a smaller heat-affected zone, making it ideal for narrower welds. Its technology allows it to run with lower current demand and better arc stability, leading to better stand-off distance and tolerances.

However, TIG welding is simpler due to the complex parameters available for plasma gas welding, which require extra training for operators. Despite this, TIG welding equipment is cheaper and requires less maintenance than plasma arc welding’s sensitive and complex torch.

Related: How Does Flux-Cored Arc Welding (FCAW) Works?

Advantages and Disadvantages of PAW

Plasma Arc Welding is a welding method that uses a torch design to control the arc, producing a high heat concentration and keyhole effect. This method allows for faster travel speeds and complete penetration of joints, with a smaller heat-affected zone compared to Gas Tungsten Arc Welding (GTAW).

However, it produces wider welds and heat-affected zones compared to LBW and EBW, requires costly equipment, requires training and specialization, produces ultraviolet and infrared radiation, and produces higher noise.

The torch is bulky, making manual welding difficult and requiring training. Overall, Plasma Arc Welding offers advantages and disadvantages in welding processes.

Related: What is Spot Welding? Its Application & How it Work