A saw is a common cutting tool in the construction and building industries. This tool cuts wood, metal, plastic, and concrete. Saw blades have teeth intended to cut different materials. The handle or frame holds the blade securely while cutting.

Saws cut lumber for framing, trim doors and windows, tile and brick for flooring and paving, and pipes for plumbing installations in the construction sector. They also make precision cuts for joints and complicated patterns in carpentry.

In this reading, we’ll learn what a saw is, its application, diagram, types, and how to use it.

Let’s get started!

Learn about List of Best Saw for Cutting Wood with this detailed guide!

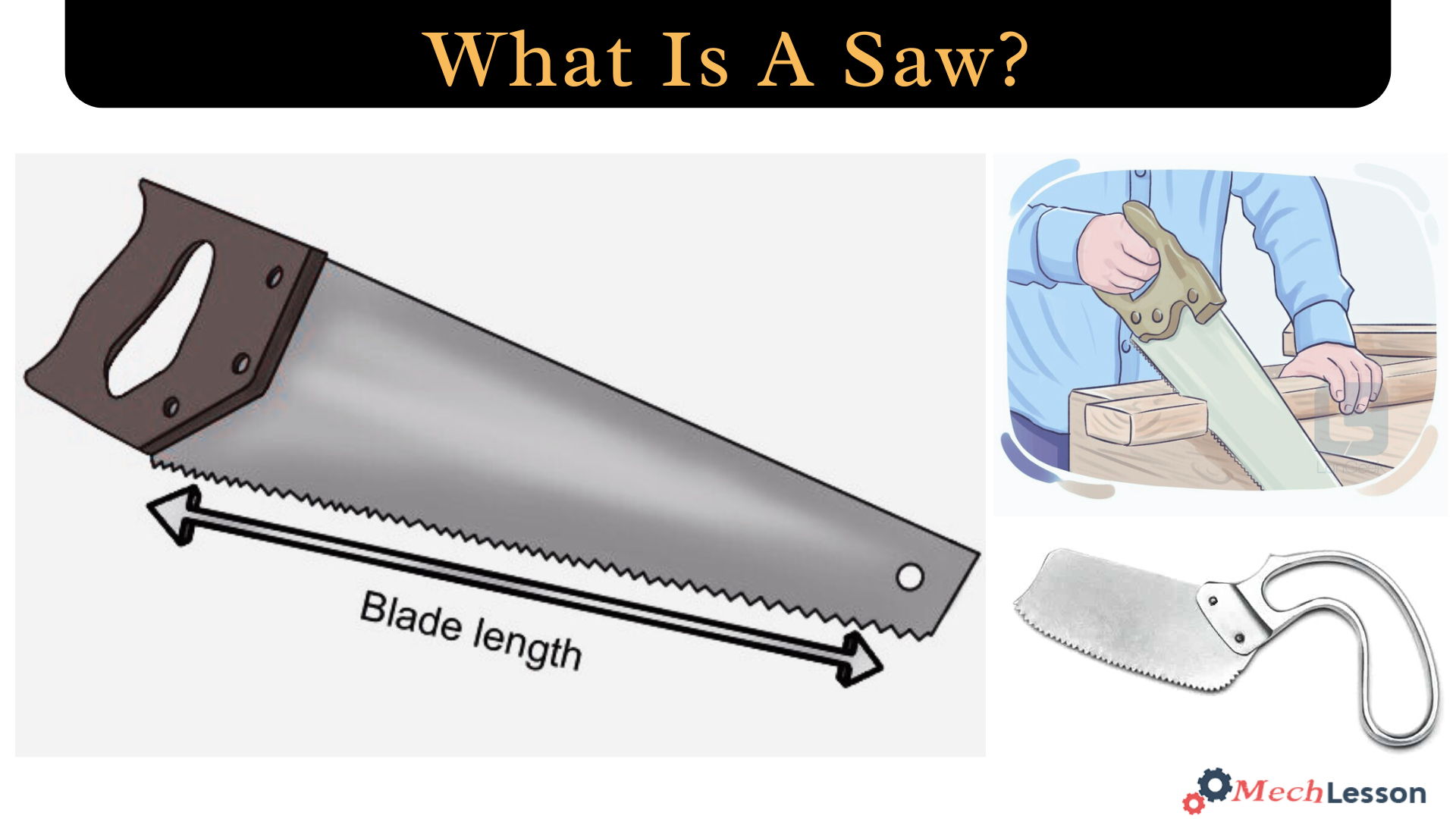

What Is A Saw?

A saw is a tool with a hard blade, wire, or chain teeth that cuts material. There are several names for toothed and abrasive saws. When man discovered how to use iron, it became the material of choice for saw blades of all types. Originally, saws were made of serrated materials. Many hand and mechanical saws have different blades and cuts.

Application Of A Saw

Applications of saws include cutting hard materials, forestry, construction, demolition, medicine, hunting, musical performance, and chainsaw carving.

- Saws are often used to cut through tough materials. They are commonly used in hunting, forestry, building, demolition, and medicine.

- Musical saws are used as instruments to create music.

- One of the most popular modern types of art is chainsaw carving. Special saws have been created specifically for this use.

- Lumber production, which produces lengths of squared wood for use in construction, begins with tree felling and log transportation to a sawmill.

- The most economical way to divide a log is to use plainsawing, also known as flatsawing, which yields the most usable pieces and is commonly used for lumber used in construction.

- Quarter sawing is a sawing method that creates edge-grain or vertical-grain lumber in which annual growth rings are more uniformly perpendicular to the pieces’ larger faces.

Diagram Of A Saw

Learn about the Best Circular Saw with this detailed guide!

Types Of Saw

There are several saws for different uses. Circular saws are used to cut plywood and other sheet materials straight. Jigsaws are great for cutting complicated shapes in wood or metal. Reciprocating saws are useful when power and speed are required for demolition work. Here’s a detailed explanation of the types of saws:

Traditional Hand Saw

This is the most common saw. The blade is large and sturdy, and it is powered by muscles. This wood-cutting tool is very reliable. Traditional handsaw blades have 1–10 TPI.

Hacksaw

Hacksaws cut pipes, steel sheets, and other metals using thin, interchangeable blades. A C-shaped frame tensions the blade, which features many small, sharp teeth. Hacksaws average 14–32 TPI. Tension nuts are common on hacksaws. This lets you adjust blade tension for your application.

Bow Saw

Bow saws are metal-framed crosscutters. You can trim trees, cut logs, and make other rough cuts with this rough-cut saw. Bow saws cut with long blades with many transverse teeth.

Coping Saw

Coping saws cut wood curves. The coping saw frame may accommodate various blades for various materials, such as wood and metal. You can also take the blade off, thread it through anything, and put it back on the frame. This allows interior profile cutting.

Coping saws are suitable for accurate, gradual, clean cutting. Their blades have microscopic sharp teeth. Coping saws can reach 32 TPI.

Tenon Saw

Tenon saws are medium-sized backsaws used to cut tenons. The saws have short, rigid blades with a strengthened spine. Most push-stroke tenon saws cut.

Pull Saw (Japanese Saw)

Japanese saws cut wood on the pull stroke. Pull strokes are more efficient than push strokes and leave a thinner kerf, making Japanese saws popular. They may have a blade with crosscut and rip teeth. Japanese saws average 10–30 TPI.

Learn about the Best Coping Saws with this detailed guide!

Jigsaw/Reciprocating Saw

A jigsaw is an electric-powered reciprocating saw. Jigsaws cut straight lines and irregular curves in wood and metal. With jigsaws, accuracy is a problem because they tend to drift. Some have a shoe at the bottom to guide the saw. The fact that it encircles the blade further reduces the risk it poses.

Circular Saw

An electric circular saw cuts straight lines in dimensional lumber, plywood, rigid foam board, and concrete. If you do not have a table saw, circular saws serve as a fantastic alternative. You can use them to cut and frame wall studs, joists, rafters, and sheathing. A circular saw uses a sharp disc to cut material. A handle behind the blade reduces kickback. They are mainly electric but can be gasoline or hydraulic.

Table Saw

A table saw is a circular power saw that is fixed beneath a table. You may cut material by running it over the blade at different angles on the table. Table saws are ideal workshop tools since they are hefty. It can rip, crosscut, miter, and bevel.

Band Saw

These saws are power saws with long, sharp blades. Band saws are strong and blade-changeable. This makes them excellent for cutting metal, wood, and other materials. Similar to jigsaws, they drift.

Mitre Saw

Power miter saws make precise crosscuts and miters. Their angled cuts are similar to a manual miter box. Miter saws align material with circular saw blade disks and steel guides. Their massive steel bases make them stable on workshop tables. They have adjustable arms that can rise or lower and swivel from side to side to cut most angles.

Chainsaw

Chainsaws are popular power tools. The chain’s teeth travel around a blade to chop trees. Chainsaws are powerful and dangerous. They use gasoline or electricity.

Radial Arm Saw

A radial arm saw has an engine and saw blade on a lever over a saw table. Radial arm saws are useful for composite, angle, and other cuts. They are perfect for professionals and hobbyists. They have a powerful engine, precise cuts, and back support. Some radial arm saws rotate quickly, so verify blade speeds.

Scroll Saw

Scroll saws are small electric saws that cut delicate curves in wood and metal. The small, narrow blade cuts more carefully than a jigsaw but more easily than a coping or fret saw. Many scroll saws have a plastic tube that blows sawdust.

You should also learn about 11 Best Saws for Cutting Wood with this detailed guide!

How To Use A Saw

Using a saw properly depends on the type of saw and the material you’re cutting. Here’s a general guide for safely and effectively using a saw.

Mark Your Cut Line

Initially, mark the precise location of the desired cut on the wood with a square.

Position the Saw Correctly And Make a Notch

Pull the saw along the marked line. Start your cut with this notch; repeat if you want a deeper one. Ensure that the primary cut is parallel to the line you have marked by using your thumb as a guide.

Start Cutting

After that, lightly press down on the wood with the saw. Hold the blade straight up and down and not sideways. If you notice the cut going crooked, twist the blade to straighten it. If you want to keep the cut straight, you have to keep looking along the blade and the line of the cut.

Finish the Cut Carefully

Cut the wood all the way through by repeating the process. Reduce pressure after cutting almost all the way through the wood to avoid splintering. Make sure to support the cut piece to prevent splinters. After one cut, keep practicing because straight cuts take time to master. It is important to keep practicing.