Richard Schneider developed the First Electric Heating Apparatus in 1896, which is a process that involves melting solder to join metals. This process, known as soldering, is commonly used in electronics, metalworking, plumbing, roofing, and joining wires.

The solder, made of tin and lead, is melted on the surface to create strong bonds. We heat the soldering iron above 600 degrees Fahrenheit, surpassing the solder’s melting temperature. The solder core contains flux, a material used to strengthen and improve the mechanical properties of the joint.

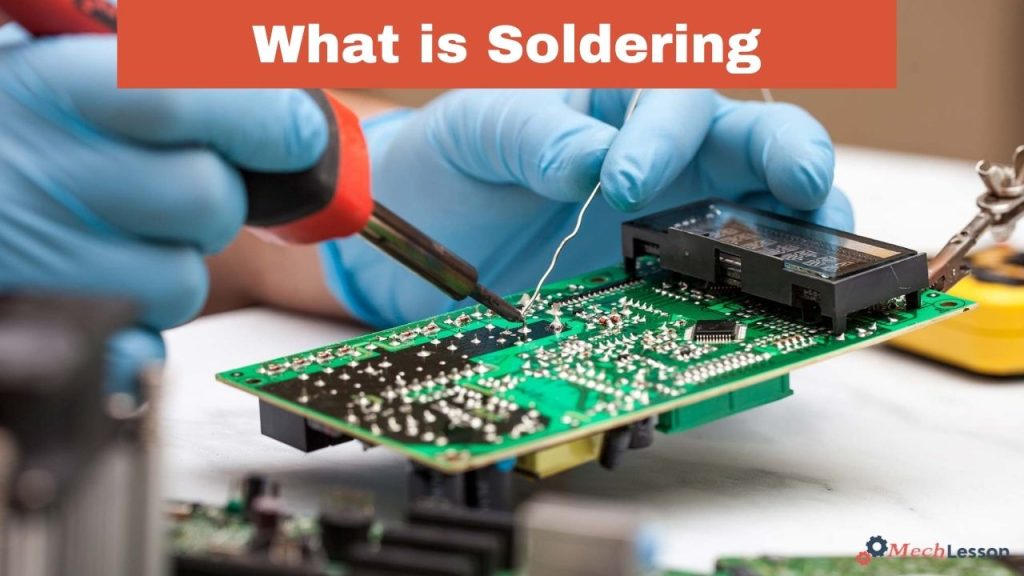

Well, in this reading, we’ll explore what soldering is, its applications, parts, equipment, diagram, and how it works. We’ll also explore what solder is, its types, and how to solder. Also, in the reading, we’ll explain what desoldering is, and the four methods of desoldering.

Let’s begin!

Related: What is Brazing? its Diagram, Types, & How it Works

What is Soldering?

Soldering is a joining process that uses a filler metal with a low melting point, typically made of tin and lead, to join metal surfaces. The solder is heated to temperatures above 600 degrees Fahrenheit, creating a strong electrical bond. Historically, lead was present in soldiers, but environmental and health concerns have led to the use of lead-free alloys for electronics and plumbing.

The solder, which is a mixture of tin and lead, has a melting point of 183°C when mixed and is melted using a hot iron above 316°C (600°F). This bond allows metal parts to achieve electrical contact while holding them in place.

At first, filler materials used in soldering were lead-based (lead solder), but over time they have been increasingly replaced with lead-free solders, which consist of bismuth, brass, copper, antimony, indium, tin, or silver.

Soldering Flux

Soldering flux is a chemical compound that helps prepare a surface for efficient soldering by improving wetting, removing oxides and enhancing the flow of the solder. flux are available in the form of liquid, paste, or core within the solder wire.

The flux used in soldering is rosin flux, as it serves different purposes on the joint, such as adding mechanical strength and electrical contact to the joint. This rosin flux also offers benefits on surfaces that contain impurities like oil, dirt, or oxidation. It helps to prevent oxidation and sometimes cleans the metal chemically. Sometimes a wetting agent will be applied to reduce surface tension.

Applications of Soldering

Soldering is a lucrative field with various applications, including in the electronics industry, plumbing, automotive, jewelry production, and vacuum tubes. It is particularly popular in the electrical electronics field, where wires are joined and electronic components fused to a circuit board.

Soldering can also be used in creating leak-proof roofing, creating joint sections in the piping and plumbing industry, and creating art in stained glass, wire modeling, sculptures, and jewelry. In the automotive field, soldering is used to fuse metal sheets, pipes, and other applications where metals don’t undergo high temperatures.

Automated soldering in circuit board manufacturing is another lucrative field where soldering is used to create a seamless and efficient assembly process. Overall, soldering is a versatile tool that can be utilized in various fields, making it a valuable tool in various industries.

Related: What is Welding, its Diagram, & How it works

Soldering Tools and Equipment

There are various tools used in soldering, which include soldering irons, soldering guns, stations, solders, and flux.

Soldering Iron

This soldering iron contains an insulated handle and a pointed metal, which is expected to be kept clean. The sharpness and cleanness of the tip will influence good soldering. A wet sponge is used to clean the tip of the soldering iron and a solder sucker is used to remove excessive solder on the tip.

Soldering iron is a hand tool used during soldering operations; it produces the high temperatures when connected to electrical power. This tool is the important one needed in a soldering setup; it is used to remove excessive solder and place the right amount on the working board.

Soldering Gun

A soldering gun is another soldering tool used on applications that require more heat, offering more heat than irons. Sheet metal, heavy electronics, and stained glass are among the applications for this soldering gun. it offers quick, neat, and perfect operation.

On the other hand, applications that require more heat than what a soldering iron can produce utilize soldering guns. They are perfectly used for joining stained glass, light sheet metal and heavy electronic soldering work. Soldering guns are more effective and quicker for heavier projects.

Soldering Station

A soldering station is a versatile power soldering device used in electronics and electrical engineering. It consists of soldering tools connected to a main unit, including controls for temperature adjustment and indication. The station may be equipped with an electric transformer and accessories like holders and stands.

The main components of a soldering station are soldering tools, such as contact soldering irons, desoldering tweezers or SMD hot tweezers, desoldering guns, hot air guns, and infrared heaters.

The soldering iron is the most common working tool, and some stations may use multiple soldering irons simultaneously for quicker and more convenient soldering. Some stations may also use specialized soldering irons, such as ultrasonic or induction soldering irons.

Related: What Is Butt Weld? Its Types, Application, And Benefits

Soldering Diagrams

Types of soldering

The three types of soldering are soft soldering, hard soldering (also known as silver soldering), and brazing.

Soft Soldering

These soldering types have the lowest filler metal melting point of about 400 degrees Celsius. Its filler metals are usually made of alloys containing lead with a liquidus temperature under 350 degrees Celsius.

This is because of the low temperatures used in soldering thermal stress components. Soft soldering is not suitable for mechanical load-bearing applications. It also cannot suit high-temperature use, as the soldering type loses strength and melts when exposed to heat.

Hard (silver) Soldering

These types of soldering use brass or silver in the bonding process. Its melting point is above 450 degrees Celsius, which can be achieved using a blowtorch. These soldering types offer strong joints.

Brazing

Brazing is the third soldering type that uses a metal with a very high melting point. The soldering process is closely similar to that of hard soldering, in which the melting point is also above 450 degrees Celsius.

The parts that require joining expose the metals to sufficient heat. The soldering metal will then be placed between them which will melt and act as a bonding agent.

Related: What is Pipe Joints? Its Diagram & Types

How Does Soldering Work?

Soldering is performed by melting solder using heat from a soldering iron or an iron connected to a temperature controller. The temperature of this heat is beyond the melting point of the solder at around 600 degrees Fahrenheit. It melts the solder, and when it cools, a soldered joint is obtained.

Flux is used during the soldering process to add mechanical strength and electrical contact to the joint. Resin flux is often used, which has the benefit of treating impurities such as oil, dirt, or oxidation on the workpiece.

However, solder can also be removed from a workpiece by using a desoldering tool. The working of soldering can be simplified into the following steps:

- Melting the Solder

- Cleaning the Components

- Placement of PCB

- Application of Solder

- Cleaning

What is Solder?

Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. It is melted after cooling to adhere to and connect the pieces, requiring an alloy with a lower melting point than the pieces being joined. The solder must be resistant to oxidative and corrosive effects and have favorable electrical characteristics.

Soft solder has a melting point range of 90 to 450°C and is commonly used in electronics, plumbing, and sheet metal work. Alloys that melt between 180 and 190 °C are the most commonly used. Hard soldering, silver soldering, or brazing is performed using alloys with a melting point above 450 °C.

Some alloys are eutectic, meaning their melting point is the lowest possible for a mixture of components and coincides with the freezing point.

Non-eutectic alloys can have different solidus and liquidus temperatures, and their pasty state can be exploited in plumbing for watertight joints. Solder wire is available in various thicknesses for hand-soldering, manual soldering, preformed foil, or small “tabs” for in-field repairs.

Related: What is Fricton Stir Welding? Its Diagram & How it works

What are the Types of Solders?

The three main types of solder are lead-free or without lead, lead-base and flux.

Lead Free Solders

Lead-free solders were created to reduce the usage of hazardous materials. These are made of metals with higher melting points, such as tin, copper, bismuth, silver, brass, indium, and antimony, and are typically soldered wire.

The EU has introduced regulations on lead in consumer electronics, leading to the development of lead-free solder. This solder offers tax advantages in the US due to its use of conformal coatings, nickel additives, and improved annealing processes, which reduce tin whiskers.

Lead-Base Solders

Soldering projects often use lead solder with a 60-40 tin-to-lead ratio, melting in 180-190°C. This solder, known as soft solder, started the electronics revolution. Lead inhibits tin whisker growth, while tin’s lower melting point makes it the preferred choice.

The higher the tin concentration, the better the tensile and shear strengths. The 60/40 mixture, also known as soft solder, is commonly used in soldering electrical connections.

Flux Core Solders

Flux core solder, a filler metal used in soldering wires, releases a protective layer around the workpiece during soldering. This process reduces metal at the contact point, resulting in cleaner electrical connections and improved wetting properties.

Acid cores, typically used for metal repairs and plumbing, are not suitable for use on electronics. Flux, typically rosin, is a crucial component in electronics.

How to Solder

Soldering is a process used to connect electronic parts by melting solder around the connection. A copper pad is used to create a strong electrical bond between the parts. To begin, insert the cables from the LED into the circuit board holes and bend them outward at a 45-degree angle. Turn on a soldering iron and heat the joint to 400°C.

Hold the iron in place for 3-4 seconds to heat the pad and lead. Apply solder to the joint, ensuring the solder is hot enough to melt the solder when touched. Snip the leads and let the solder cool naturally.

A proper solder joint should be smooth, shiny, and resemble a volcano or cone shape. Avoid blowing on the solder to avoid a bad connection. After cooling, cut extra wire from the cables.

What is Desoldering?

Desoldering is a crucial process in electronics, involving the removal of solder and components from a circuit board for troubleshooting, repair, replacement, and salvage. It involves melting the solder and removing the joints between two materials.

Desoldering is the opposite of soldering, requiring proficiency and adherence to strict safety measures. Electronics commonly use it to repair, replace, and salvage electrical components from PCBs. Both processes are intricate and require careful attention to detail.

Related: What is Gas Welding? Its Diagram, Types & How it Works

Methods of Desoldering

Desoldering can be achieved in four methods, which include using a soldering iron, using soldering wick, using a soldering pump, and using a heat gun.

Using Soldering Iron

A soldering iron is the easiest method to remove components from a project. It requires heating the solder until it melts, nudging pins, and pulling components from pinholes using pliers.

Apply pressure at the tips instead of their bodies to avoid damage. A safety pin can be used to remove solder from holes for easier removal.

This method is simple, cost-effective, and can be reused. However, prolonged use may damage the board. Overall, a soldering iron is the most effective tool for desoldering components.

Using Soldering Gun

The method of using a desoldering pump to remove solder involves heating and melting the solder. The process involves using a soldering iron to heat the solder until it melts, then placing the desoldering pump on the molten solder, releasing the bulb to suck up the solder, and repeating the same steps until excess solder is removed.

Some desoldering pumps come with a soldering iron, making disposing of the solder easier.

You can reuse this method to remove solder from pinholes and desolder small components. However, the large size of desoldering pumps may make it difficult to fit into tight spaces. Despite these drawbacks, the desoldering pump is a convenient and efficient tool for removing solder from various components.

Related: What is Tack Welding? Its Diagram and Benefits

Using Soldering Wick

The soldering wick method is a cost-effective and simple way to remove unwanted solder from metal surfaces. It involves braiding and intertwining copper coils, also known as a desoldering braid.

Since heat attracts solder, copper wires serve as effective heat conductors. Some soldering wicks come with flux, which makes it easier to remove solder from the surface. If the wick lacks flux, you can dip its end into flux to improve the removal process.

To remove solder, intertwine copper wires and form a braid. Apply flux to the copper braid, then place a portion of the solder wick on the desired joint. Place a hot soldering iron at the tip of the wick and the desired pin.

Wait for a few seconds until the solder melts and the wick sucks the melted solder. Remove the portion covered in solder and repeat the process until all unwanted solder is removed.

Pros of the soldering wick method include being cheap, simple, and easy to use; being suitable for flat surfaces; and reusing desoldered components. However, it is not possible to reuse the soldering wick, as it must be cut to remove the solder. Additionally, the soldering wick can be difficult to position against the joint due to its high heat.

Using A Heat Gun

A heat gun is a tool that heats up solder to remove components from a PCB. Similar to a soldering iron, it is used to desolder components. To use a heat gun, hold the PCB firmly and hold the tip against the solder until it melts.

Remove the components using pliers. It is important not to hold the heat gun against the board for too long to avoid melting or damaging it. While the process can be quick and easy, it can also cause damage to the board and injure oneself. Despite its benefits, the use of a heat gun can be costly and time-consuming.

Advantages and Disadvantages of Soldering

Soldering is a welding method that operates at lower temperatures and allows for joining most metals and non-metals. It is easy to learn and can be undone using a desoldering tool without damaging the base materials.

However, it has weaker joints compared to other welding methods like MIG and TIG, is not suitable at high temperatures, and heavy metals are not suitable for soldering.

Melted solder may leave a toxic flux residue, and improper heating may cause deformities or voids in the solder. Despite its versatility, soldering has drawbacks, such as reduced joint strength and inefficiency for long-distance joining.

Conclusion

Soldering is an essential joining process used in electronics, plumbing, jewelry making, and metalwork, where two or more components are fused using a filler metal (solder). Good soldering ensures strong electrical connections and mechanical bonds.

Mastering soldering techniques, such as proper heating, using the right type of solder, and maintaining cleanliness, is crucial for creating durable and reliable joints. Whether you’re a beginner or a professional, strong soldering skills are fundamental to quality craftsmanship.

FAQs on Soldering

What is the main purpose of soldering?

Soldering is used to join two or more metal components together by melting and flowing a filler metal into the joint.

What materials can be soldered?

Metals like copper, silver, gold, brass, and some types of aluminum can be soldered, depending on the technique and solder used.

What is the difference between soldering and welding?

Soldering uses lower temperatures and only melts the filler metal, not the workpieces. Welding melts both the filler and base materials.

Why is flux used in soldering?

Flux removes oxidation from metal surfaces, improves the flow of solder, and helps create a strong, clean joint.

Can you solder without a soldering iron?

A soldering iron is the most common tool, but other heat sources like soldering guns, torches, or even specialized ovens are used depending on the project.

What are common problems in soldering?

Cold joints, poor wetting, excess solder, and insufficient heating are common issues that can weaken the soldered connection.