The performance of a mechanical part can be determined by its surface roughness, as it is the irregularity that causes fractures or corrosion. This is to say that rough surfaces wear faster and have greater friction coefficients than smooth surfaces.

Well, in this reading, we’ll explore what surface roughness means in manufacturing and engineering, its importance, charts, and how to measure it. We’ll also explore its units and parameters.

Let’s get started!

Learn about surface finish with this detailed guide!

What is Surface Roughness?

Surface roughness is a topic discussed under surface finish; it is the fine irregularities on a product surface as a result of the manufacturing processes like machining or sanding. The measurement of surface profile can also be used for measuring smoothness through the microscopic deviation in its true form.

Surface roughness is necessary for cosmetic finish coatings like plating, powder coating, or painting.

A suitable surface finish makes items appealing and also ensures they work as expected. So, knowing the surface roughness in manufacturing is crucial for creating the best surface finish and manufacturing procedures.

Tools like stylus profilometers are commonly used to measure these deviations, providing vital data for ensuring a surface meets desired roughness standards for its specific application.

Surface roughness refers to irregularities in the production process, such as vibrations from abrasive grit or cutting tools. It is quantified by deviations in the direction of the normal vector of a real surface from its ideal form.

Large deviations indicate roughness, while small deviations indicate smoothness. Waviness, a part of the texture, may result from vibrations, chatter, or work deflections. It is impossible to precisely determine where waviness stops and its shape becomes part of the general form of the part.

You should also learn about powder metallurgy with this guide!

Unit of Surface Roughness

Surface roughness is a common unit of measurement, often expressed as the calculated average between peaks and valleys on a surface. A lower Ra value makes the surface smoother, while a higher Ra value may result in highly textured and coarser products.

This contrast highlights the importance of determining the desired surface roughness before manufacturing, as machining finishes may vary significantly without such determinations.

Ra serves as the numerical average of all peaks and valleys across the test.

Rz is the average of consecutive highest peaks and lowest valleys.

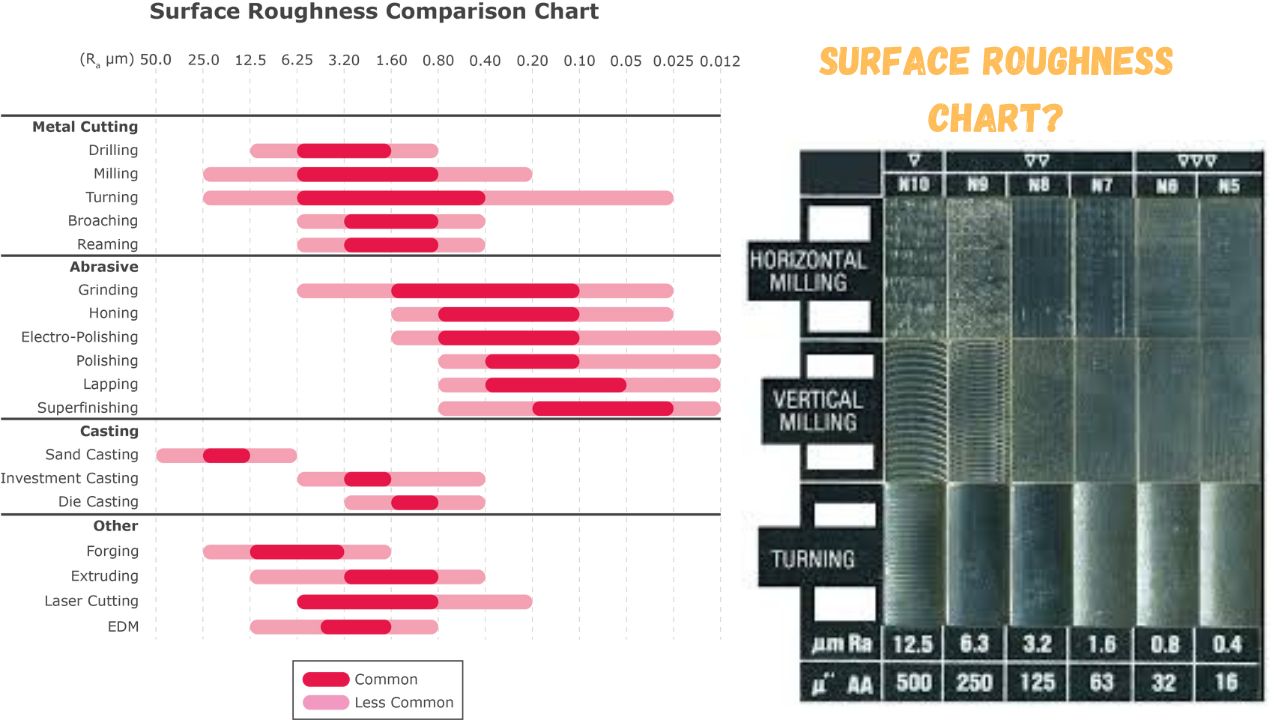

Roughness Charts

What are the Importance of Surface Roughness?

- Surface roughness is crucial in cleaning, wear, and manufacturing.

- Rough surfaces are more prone to wear and have higher friction coefficients.

- It is ideal in industries like food processing and pharmaceuticals.

- Anodizing, an electrolytic process, can affect surface roughness.

- Roughness determines how an object interacts with its environment.

- High roughness values are undesirable but costly to control.

- Decreasing roughness increases manufacturing costs.

- Surface profile measurements can be done manually or using a profilometer.

- Controlled roughness is desirable, as glossy surfaces may be too shiny or slippery.

Learn about grinding with this detailed guide!

How to Measure Surface Roughness?

Surface roughness is a crucial aspect of manufacturing and quality control, ensuring a product meets the required specifications and is suitable for its intended use.

Various methods are used to measure surface finish roughness, including direct measurement methods, non-contact methods, comparison methods, and in-process methods. Direct measurement methods involve drawing a stylus perpendicular to the surface, allowing the machinist to determine roughness parameters.

Non-contact methods use light or sound, such as white light and confocal, to measure surface roughness. These instruments can be switched with optical sensors or microscopes to assess the reflected waves and determine roughness parameters.

Comparison techniques use surface roughness samples generated by equipment or process, allowing the manufacturer to compare results against known roughness parameters.

In-process techniques, such as inductance, evaluate surface roughness using magnetic materials, using electromagnetic energy to gauge the distance to the surface and determine comparative roughness parameters. These methods help in ensuring the quality of a product and its suitability for its intended use.

Conclusion

Surface roughness refers to the fine irregularities and deviations present on a material’s surface, typically resulting from the machining or manufacturing process. It directly affects how parts fit together, their friction and wear characteristics, and even their appearance.

Accurately measuring and controlling surface roughness is crucial in industries like automotive, aerospace, and precision engineering. Different applications require specific levels of roughness—ranging from highly polished surfaces for seals to rough textures for adhesion. Understanding and optimizing surface roughness enhances product quality, performance, and lifespan.

Learn about machining with this detailed guide!

FAQs on Surface Roughness

What is surface roughness?

Surface roughness is the measure of the texture of a surface, defined by its small, finely spaced deviations from the nominal surface.

How is surface roughness measured?

It is typically measured using tools like contact profilometers or non-contact optical devices, and reported in micrometers (µm) or microinches.

What does Ra mean in surface roughness?

Ra stands for Roughness Average, which is the arithmetic average of the absolute values of surface height deviations from the mean line over a specified length.

Why is surface roughness important?

It affects part performance, including wear, friction, lubrication, fatigue resistance, and sealing effectiveness.

What are common surface roughness symbols used in drawings?

Symbols like Ra, Rz, and Rt are used to specify the surface finish requirements on technical drawings.

How can surface roughness be improved?

Through processes such as grinding, honing, lapping, polishing, and superfinishing.

Is surface roughness the same as surface finish?

Not exactly. Surface finish includes roughness, waviness, and lay, while roughness specifically refers to the finer irregularities.