Woodworking joints are methods used to connect pieces of wood, offering various levels of strength, durability, and aesthetics, and are essential for a wide range of woodworking projects. There are various types of woodworking joints available to woodworkers. They offer a different level of strength to workpieces and are suitable for a specific project.

Well, in this reading, we’ll be exploring the various types of wood joints, their uses, pictures, and how they are performed.

Let’s begin!

Read about Softwood Plywood and Hardwood Plywood with this detailed guide!

What are the Types of Wood Joints?

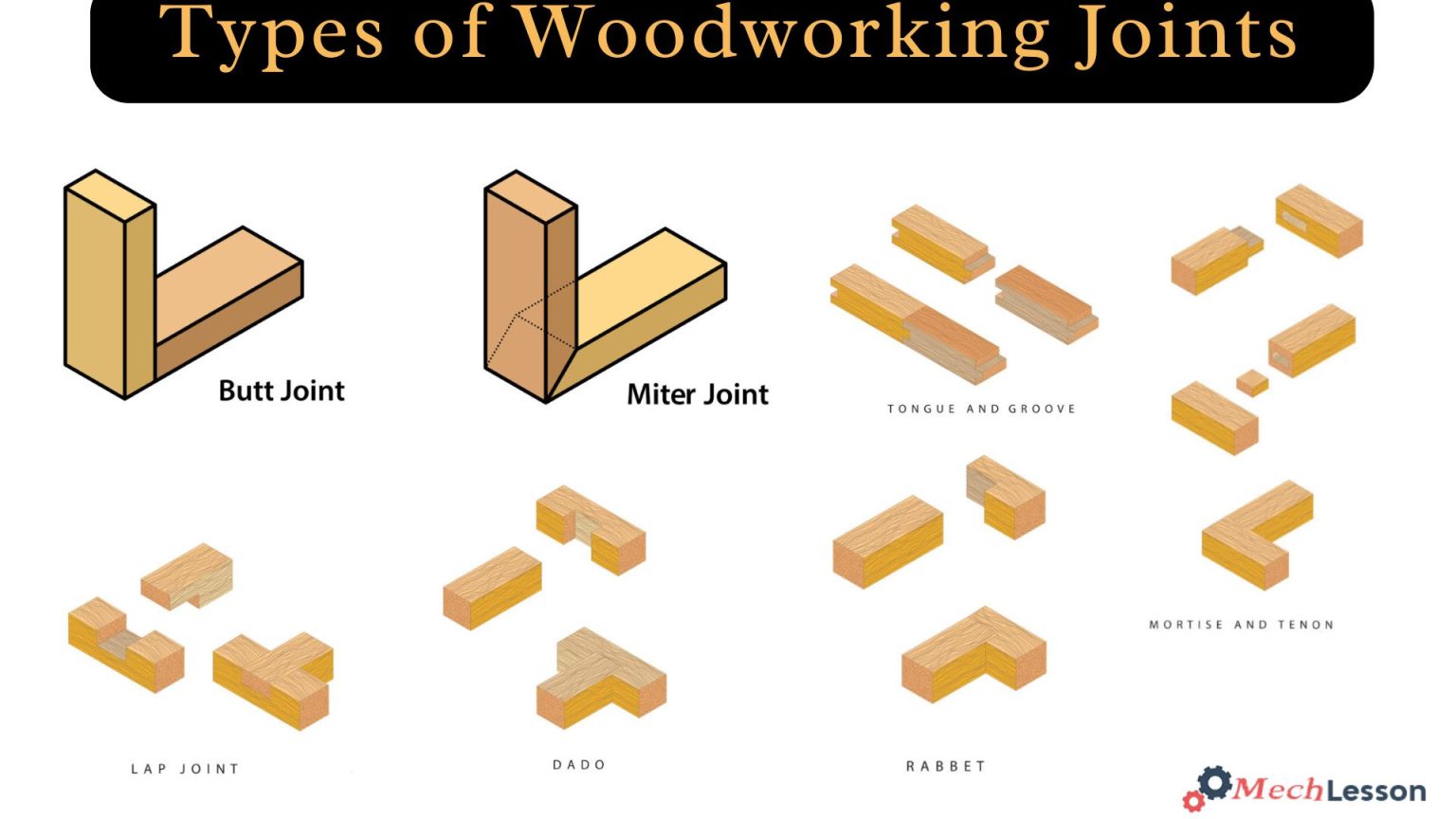

The various kinds of woodworking joints include:

Butt joint:

A butt joint is the most common and easiest type of woodworking joint, which joins two pieces of wood mere by butting them together. It is the simplest joint to make and it is a weaker joint only if reinforcement is employed.

The joint depends upon glue alone to hold the pieces together, which result in a weaker joint. This is because glue does not offer much literal strength.

Biscuit Joint

This joint is just like a butt joint that contains reinforcement and shaped in oval form. Biscuit joint is generally made of dried and compressed wood such as beech which is installed in matching mortises in both pieces of the wood joint.

People often use the biscuit joiner to create the mortises where the accuracy is not that important. The design of this joint allows flexibility in glue-up. The mortise must be located at a correct distance in the face of the wood joint in both pieces.

Width of the mortises is not critical since the biscuit is thin making the alignment to move around. Though the alignment is not perfect.

Read about 33 Types of wood and their uses with this detailed guide!

Miter Joint:

An angled cut and the saw used to accomplish it are both referred to as “mitres.” These types of joints describe two 45-degree angled cuts where the wood pieces meet to form a 90-degree angle.

Miter butt joints can be cut at any angle, although the most common miter joints are 45 degrees. For instance, you would cut each miter to 22.5 degrees if you wanted to construct an octagonal structure.

Miter joints are often used at the outside corners of picture frames, doors, and windows. They still need glue and mechanical fasteners to stay in place, but they are stronger than butt joints because the two pieces of wood meet on a larger surface area.

Bridle Joint:

The bridle kind of joint is similar to the mortise and tenon joint. It contains a tenon on the end of one piece and a mortise on the other workpiece which will accept the tenon.

This joint has three glueing surfaces. In a corner bridle joint, two pieces are joined at their ends, creating a corner. It can be used to house a rail in uprights, such as legs, because it provides good strength in compression and its ability to moderately resist racking.

It is also used to join frame pieces when the frame is shaped. A mechanical fastener and pin are required in the woodworking joint.

Dado Joinery:

A dado is a slot cut into the surface of wood pieces, usually used to attach shelves to a bookcase carcass. It has three sides when viewed in cross-section, and it is cut perpendicularly to a grain, making it different from the groove, which is cut parallel to the grain.

Dovetail Joint:

A dovetail joint is a strong woodworking joint that is great for tensile strength (resistance from pulling apart). It is often used to connect the sides of a drawer to the front. People often use a dovetailed dado because of the tensile strength it offers.

The joint is permanent when glued, and it requires no mechanical fasteners. In addition to the making, there is a series of pins cut to extend from the end of one board that interlock with a series of tails cut into the end of another board.

This pin and tail have a trapezoidal shape.

Finger Joint:

The finger joint is a popular type of woodworking joint also called a box joint. It is used to join two pieces of wood at right angles to each other, which makes it similar to a dovetail joint except that the pins are square and not angled.

A finger joint does not have mechanical strength like a dovetail, as it relies on glue to hold the parts together. The joint is easy to make if one knows how to work with a table saw or a wood router with a simple jig.

Coped Joint:

The counterpart to the mitre joint that sits beneath it is called a coped joint. It deals with the fact that many rooms’ corners do not actually meet at a 90-degree angle.

The two pieces of wood that comprise these types of joints are cut like jigsaw pieces to provide an uneven yet tailored fit behind the outside (visible) mitre joint.

Lap Joint:

Lap joints are of different types, but the most frequently used is a half lap joint. it joint is produced by removing an equal portion from each piece in order to obtain the same thickness of the piece when joined. The joint is suitable for making workshop storage items.

Read about Wood Finishes with this detailed guide!

Half Lap Joint:

The two pieces of wood that comprise these types of joints are cut like jigsaw pieces to provide an uneven yet tailored fit behind the outside (visible) mitre joint.

The ends of the two adjacent pieces of wood are cut to half their thickness where they overlap when using a half-lap joint.

Although there are stronger joints, half-lap joints are more aesthetically pleasing than butt joints because they keep the thickness consistent with the rest of the construction.

Because of its benefits, half-lap joints are often used in framing and furniture building. This is because the frame’s thickness stays constant, whereas other joints frequently cause the thickness to increase compared to the rest of the structure.

Half-lap joints work better with thicker wood since thin wood can become considerably weaker when it loses half of its thickness.

Mortise and Tenon Joints:

Mortise and tenon joint is one of the strongest wood joints performed by carpenters. It is simple to make. Normally you join two pieces at 90 degrees, with one end of a piece being inserted into a hole in the other workpiece.

The end of the first workpiece is the tenon, while the hole in the second piece is called the mortise. Glue is used to make the joint, and one may pin or wedge it to lock the joint in place. There should be a perfect registration between the two pieces.

The mortise is a cavity cut into a piece of wood that allows a tenon to enter, while the tenon is a projection on the end of a piece of wood which is inserted into a mortise. The side of the mortise and tenon is determined by the thickness of the workpiece.

Pocket-Hole Joinery

The pocket hole is one of the most popular woodworking joints, which is just like a butt joint with a pocket hole screw. Two drilling operations are performed when making the joint; the first is counterboring of the pocket hole that collects the screw head on the workpiece.

The second hole is to drill a pilot hole that has the same centerline as the pocket hole. This pilot hole allows the screw to pass through a piece to the adjoining piece. two different drill bits are used for the drilling operation.

Rabbet joinery

The rabbet type of woodworking joint contains a recess cut into the edge of a wood piece. They are two-sided and an opening to the end of the surface when viewed in cross-section.

The rabbet joint is found at the back edge of a cabinet, which allows the back to fit flush with the sides.

Tongue and groove joint

Edge-to-edge joints are commonly used in woodworking. A one-piece that contains a slot (groove) is cut all along one edge, and the other piece has a tongue cut on the mating edge.

This results in fitting two or more pieces closely together. Tongue and groove joints are often used to make wide tabletops out of solid wood and can also be used in wood flooring, parquetry, panelling, etc. the joint can be cut in a number of ways.

Box Joint:

These types of joints are strong and visually appealing joints where interlocking rectangular grooves are cut into the edges of two pieces of wood, often used in drawer construction.

Pocket Joint:

Pocket joints are simple and strong joints where angled holes are drilled into the wood and screws are used to join the pieces. They are often used for furniture construction.

Finger Joint:

Interlocking finger-like projections and recesses are cut into the ends of two pieces of wood, then glued together, creating a strong and visually appealing joint.

Related: Wood Finishes: Types, and How to Choose the Right One

FAQs

Is a joiner a woodworker?

But expert joinery is actually a specialist skill within the wider realm of woodwork, with a joiner focusing more on creating frames, panels and components involved in construction.

What are the basic woodworking joints?

To start with, a butt joint is the most basic wood joint because it simply butts two pieces of wood together. Since this wood joint can’t lock each board together, it needs glue or countersinking nails to stay in place. Application: Butt joints are often used around window trims and baseboards.

What is a woodworking joint called?

Common types of joints include the dovetail, used for joining two flat members together at right angles, as in the sides of a drawer; the dowelled joint, in which dowelling is employed to impart mechanical strength; and the mortise and tenon, used to join a horizontal member with the vertical member of a frame.