Butterfly valves, which belong to the quarter-turn valve family, function similarly to ball valves. A disc attached to a rod is what the “butterfly” is.

When the rod turns the disc a quarter turn to a point perpendicular to the direction of flow, it shuts. When the valve opens, the disc is rolled back to let the flow.

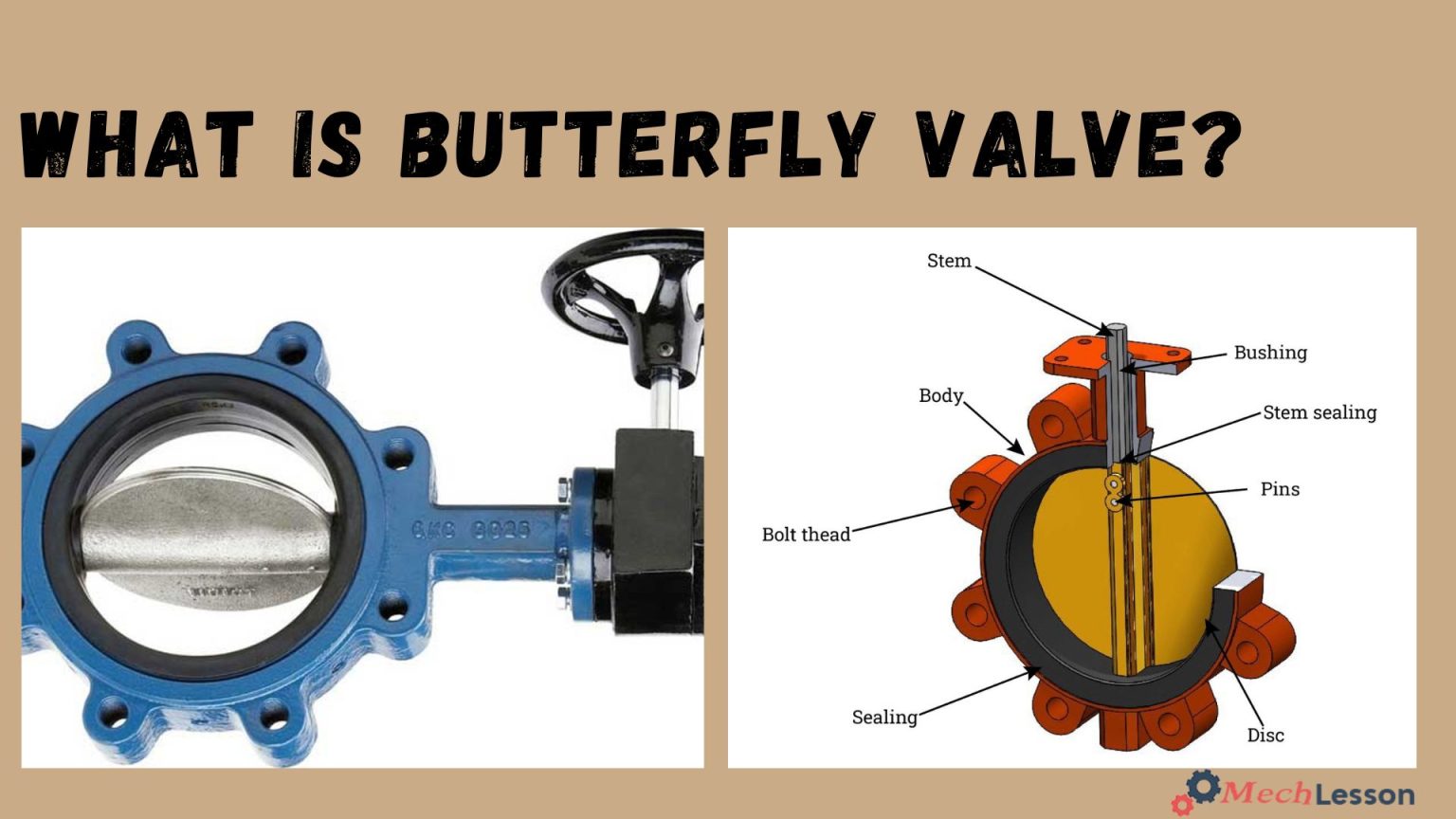

A butterfly valve is a type of valve used to control or isolate fluid flow. A rotating disk serves as the closing mechanism. Well, in this reading, we’ll explore what a butterfly valve is, its applications, functions, parts, diagrams, types, and how it works. We’ll also look at its advantages and disadvantages.

Let’s begin!

Learn about Pressure Relief Valve with this detailed guide!

What is a Butterfly Valve?

Butterfly valves are a class of quarter-turn rotating motion valves that stop the flow of fluid in pipelines. Butterfly valves are frequently used as a means of controlling flow.

They have a wide range of applications, particularly in flow isolation, and are used in many different process media and industries, particularly in water supply, collection, and distribution, as well as pumping stations.

Their straightforward design and compactness, which lead to lighter and less expensive final products with smaller installation footprints and faster actuation rates, are two of their main advantages over other valve families.

Flanged double eccentric (double offset) butterfly valves are the Hawle type. This valve design incorporates two offsets of the disc from the center of the valve body or the stem’s axis of rotation, which is known as the double offset or eccentricity.

Just as mentioned earlier, the butterfly valve is a type of valve used to control or isolate fluid flow. A rotating disc serves as the closing mechanism.

Butterfly valves function similarly to ball valves, as a disc attached to a rod is what the “butterfly” is. When the rod turns the disc a quarter turn to a point perpendicular to the direction of flow, it shuts. The disc is rolled back to let the flow when the valve opens.

Butterfly valves are used for modulating or on-off services, and they are widely utilized because they are inexpensive, lightweight, easy to install, operate quickly, and come in a wide range of sizes. Handles, gears, or automated actuators can be used to operate these valves.

Applications

Butterfly valves are used in various industries today because they help to regulate flow by starting, slowing, or serving as stopping media.

They are quite useful across a wide range of applications due to their lighter weight. They are common in the agricultural industry, medical, food, shipping, etc. Also, butterfly valves are ideal for large-volume water applications and slurry applications.

Butterfly valves are commonly used in cooling water, air, gases, fire protection, etc. Slurry and similar services, vacuum service, and high-pressure and high-temperature water. They are also used in steam services and compressed air or gas applications

You should learn about Needle Valve with this detailed guide!

Parts of a Butterfly Valve

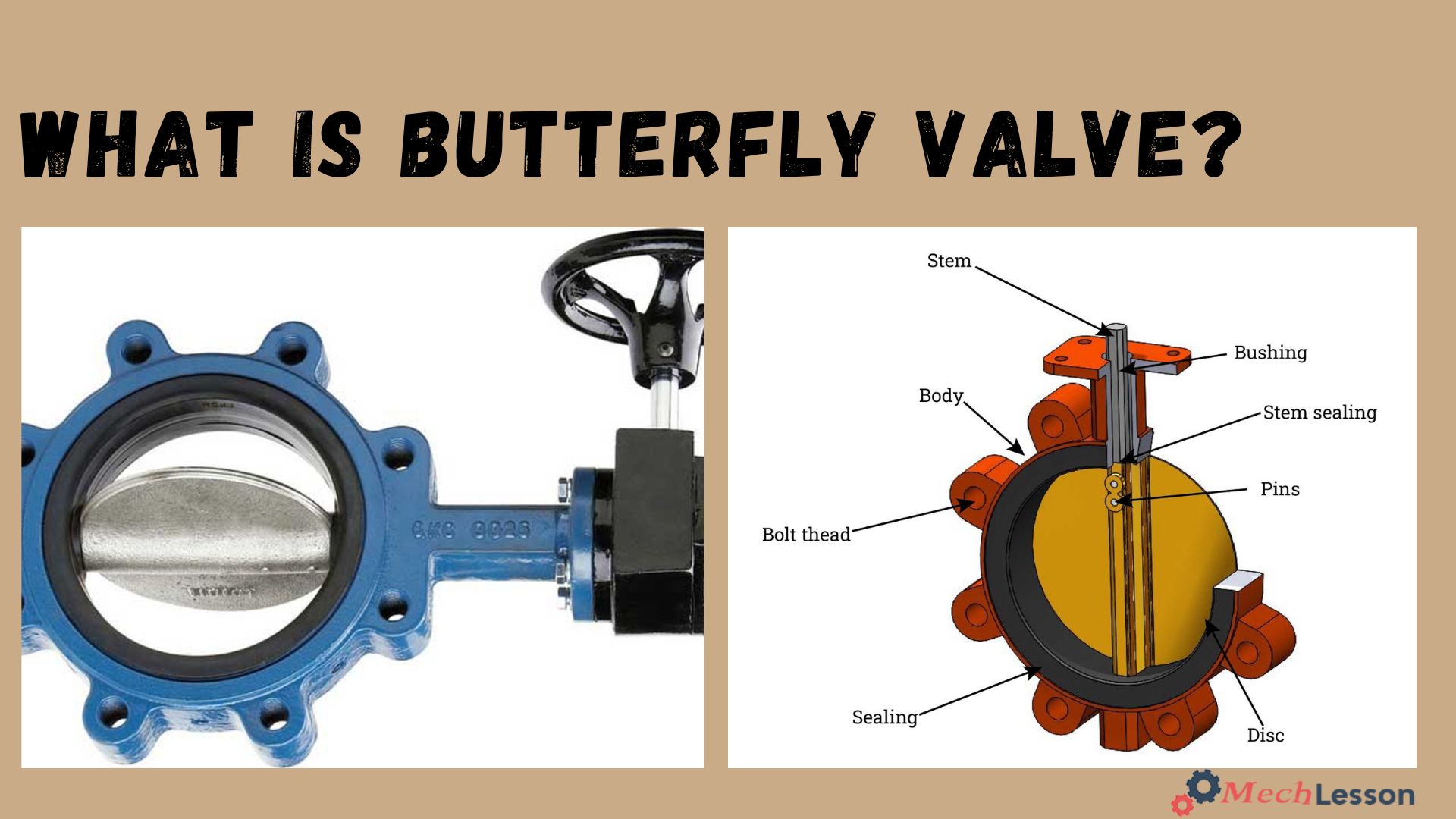

The major components of a butterfly valve include the valve body, disc, seat, stem, and seal.

1. Valve Body – The valve body fits between the pipe flanges. The most popular end connection types are flanged, double lug, and wafer.

2. Disc – The disc that acts as a gate to stop or throttle fluid flow is attached to the valve body; it is comparable to a ball in a ball valve or a gate in a gate valve.

3. Seat – To accomplish total closure, a solid metal anti-leak seal or elastomer lining the inside valve body holds the disc firmly in place when it is closed.

4. Stem – The part that joins the disc to the actuation mechanism and transfers the torque through itself is the valve shaft, sometimes called the stem.

5. Seal – Multiple interfaces inside the valve include seals to either separate the process from the internal components of the valve. This helps to achieve a more flexible and economical design or to guarantee a tight seal when the valve is in operation.

Diagram

You should also learn about PCV Valve with this detailed guide!

Types of Butterfly Valves

Below are the various types of butterfly valves based on their alignment and disc configurations:

- Wafer Types

- Lug Style

- Flanged Type

- Butt Welded Ends Types

- Zero offset Butterfly Valve

- Double Offset Butterfly Valve

- Triple Offset Butterfly Valve

- Metal Valve

- Plastic-Lined Valves

- Rubber-Lined Valves

How Does a Butterfly Valve Work?

A butterfly valve functions similarly to a ball valve, enabling rapid shut-off. Because they are less expensive than other valve types and require less support due to their lighter weight, butterfly valves are typically used. The disc is placed in the pipe’s centre.

A rod travels to an actuator on the valve’s surface through the disc. The actuator may be rotated to make the disc parallel or perpendicular to the flow. In contrast to a ball valve, the disc creates a pressure decrease even while it is open since it is constantly in the flow.

The disc is turned a quarter turn to provide nearly unrestricted fluid flow while the valve is fully open. To throttle flow, the valve can also be opened gradually.

Butterfly valves come in a variety of types, each designed for a particular pressure and use. The butterfly valve with the lowest pressure rating is the zero-offset kind, which makes use of rubber’s elasticity.

When used in systems with a higher pressure, the high-performance double offset butterfly valve is offset from both the bore’s centerline (offset two) and the disc seat and body seal’s centerline (offset one).

By lifting the seat out of the seal during operation, this produces a cam motion that reduces friction compared to the zero offset design and lessens the possibility of wear. The triple offset butterfly valve is the valve most appropriate for high-pressure systems.

Because of the offset disc seat contact axis in this valve, sliding contact between the disc and seat is essentially eliminated. The metal seat of triple offset valves can be machined to create a bubble-tight shut-off when it comes into contact with the disc.

Learn about Ball Valve with this comprehensive guide!

Advantages and Disadvantages of a Butterfly Valve

Butterfly valves are small, lightweight, and precise valves that are ideal for industrial applications due to their quick opening and closing, low structural support, and ability to throttle flow.

They require minimal maintenance and can be installed or removed without pipe system dislocation. They offer a variety of actuation methods, are available in large diameters, and come in various materials such as full stainless steel and lightweight aluminum bodies.

However, one disadvantage is that some parts of the disc always face the flow, leading to a pressure switch across the valve regardless of the setting.

Additionally, butterfly valves have poor sealing function, throttling is restricted to low-pressure drop systems, and there is a concern of potential cavitation and choked flow when they operate.

You should learn about Diaphragm Valve with this detailed guide!

FAQs

What is a butterfly valve used for?

Butterfly valves for water are used as control valves in pipelines to shut off water flow. These valves are available in huge sizes and are suitable for handling slurries and liquids with relatively large amounts of solids at low pressures.

What does a butterfly valve do in a car?

It supports the shaft of the throttle valve and controls its operation. The butterfly valve opens and closes based on how far the accelerator pedal is pressed. Early fuel-injected cars have a cable connecting the gas pedal to the throttle body that mechanically pulls the butterfly valve open.

What is the difference between a gate valve and a butterfly valve?

Gate and butterfly valves are both used to turn on and off the flow, but butterfly valves can also regulate flow via partial disc closure. Butterfly valves are part of the quarter-turn family of valves and can be shut off much faster than gate valves, which are multi-turn valves.

What is the function of the butterfly check valve?

The primary purpose of butterfly check valves, like all check valves, is to ensure unidirectional flow of fluids in a system. They prevent the backward flow or backflow of fluids, which is critical in many fluid systems to maintain efficiency, protect equipment, and avoid potential disasters.

What is the difference between a butterfly valve and a check valve?

Butterfly valves consist of a circular disc that rotates within the valve body, controlling the flow of fluid through the pipe. They are often used in large-diameter piping systems where cost and weight are a concern. Check valves, on the other hand, allow fluid to flow in only one direction, preventing backflow.