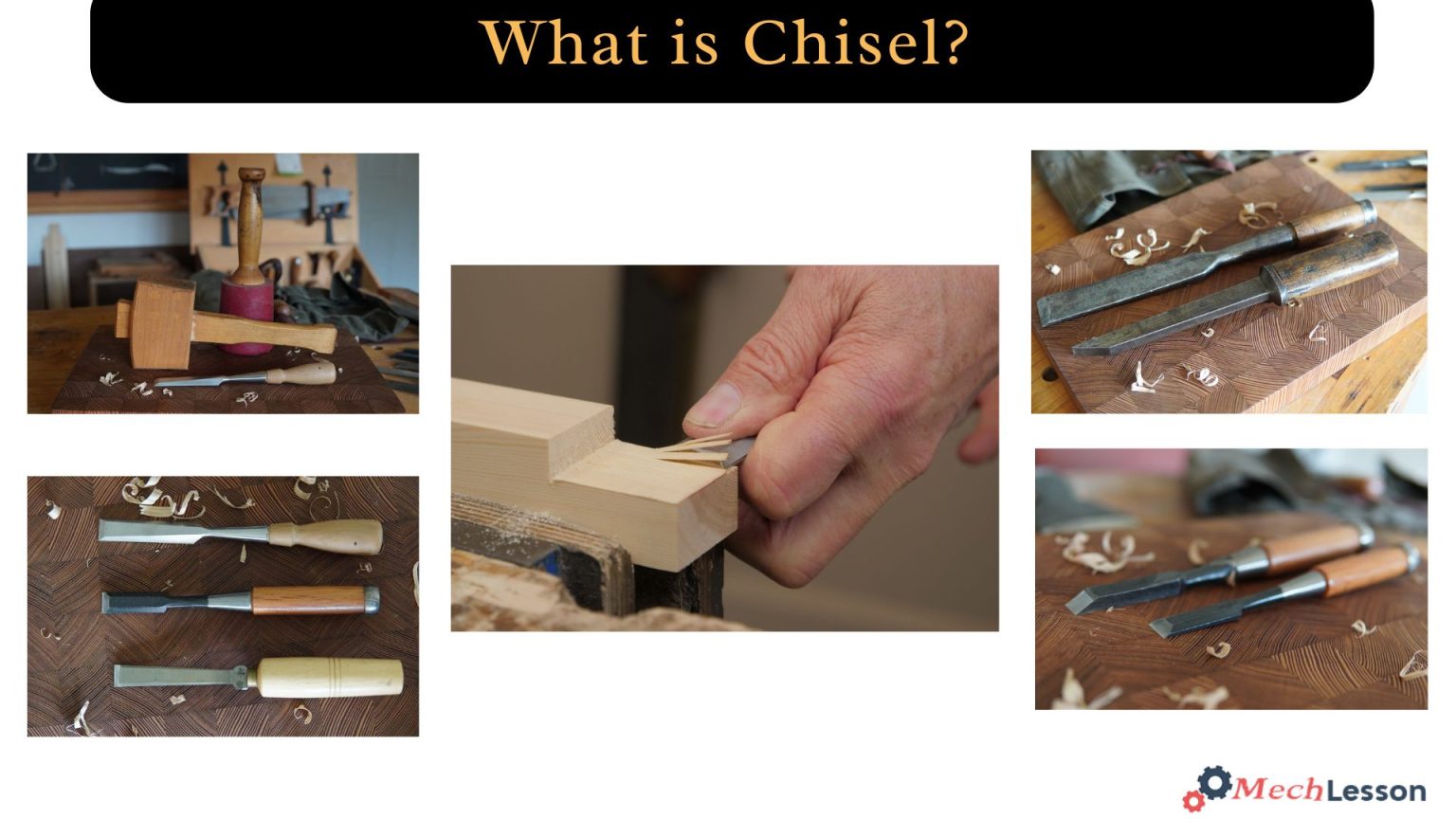

Chisels are wedged hand tools with a shaped cutting edge on the end of their blade. It is used for carving and cutting hard materials like wood, stone, and metal. They are used by hand, struck with a mallet, or by mechanical power

The chisel is one of the most essential hand tools in a woodworking workshop. There are different types, each suited to special operations. Chisels are known for their wide applications, such as edge refining, mortice cleaning, cuts, joints, and carving wood.

Chisels are cutting tools that come in different types, designs, shapes, styles, and sizes. Well, in this reading, we’ll explore what a chisel is, its diagram, and its types. We’ll also explore the purpose of a chisel on wood.

Let’s begin!

Read about Brick Chimney with this detailed guide!

What is a Chisel?

A chisel is a hand tool with a sharp, bevelled edge used for carving, shaping, or cutting hard materials like wood, stone, or metal, often with the aid of a hammer or mallet. Chisels are common tools used to form wood. To chisel, the blade must be forced into the material. Applying the driving force can be done manually or using a hammer or mallet.

A cutting tool may be driven into the material in an industrial setting using a hydraulic ram or falling weight (sometimes known as a “trip hammer”). Since they were first used 8,000 years ago, chisels have been a popular tool among craftsmen.

Wood can appear a little nicer by having the corners cut off with a chisel. They can form mortise and tenon joints, dado joints, or dovetail joints to link two pieces of wood. With a chisel, you may take use of the way the tree develops and the inherent strength of wood to create the strongest joint possible between two pieces of wood.

Uses of Chisels

- Chisels are used to carve, shape, and cut various materials, including wood, stone, and metal.

- In woodworking, chisels are used for tasks like cutting joints, shaping wood, and creating intricate details.

- Chisels are used in masonry to cut, shape, and scrape stones and bricks.

- Chisels are used to cut and shape metal, particularly when other tools like tin snips are not suitable.

- Paring Chisels are used for fine, precise work and removing small amounts of material.

- Mortise Chisels are used for cutting mortise joints in woodworking.

- Framing Chisels are used for rougher work and removing larger pieces of wood.

- Cold Chisels are used for cutting and shaping metal, particularly when the metal is thick or difficult to cut with other tools.

- Stone Chisels are also used in masonry to cut, shape, and scrape stones and bricks.

Read about Types of Wooworking Hand Tools and Power Tools with this detailed guide!

Diagram

Types of Chisels

The various types of chisels include:

Beveled Edge Bence Chisels:

The bevelled-edge types of chisels are used mostly on cabinet projects, though they apply to other jobs. It is highly considered, as its operation is simple and straightforward, just like other chisels.

This chisel is used by firmly holding the edge with a hand and using a hammer to hit the top part. All woodworkers are expected to invest in a complete set of this chisel, as it will be ready to go long-term for a variety of woodwork projects.

Read about Names of Different Types of Hammers, Their Uses and Diagram with this detailed guide!

The hand tool also experiences wear and tear, but one made of the right tools could last longer. It is available in different sizes, as a woodworker will need a complete set for immense projects.

Finally, the bevelled edges on each side feature blades of moderate thickness. These make them be used under intense force but still remain in shape. only when it edges needs to be sharp.

Heavy-Duty Bevelled Edge Chisel:

The heavy-duty bevelled edge chisel looks like the bevelled edge type, but their applications totally differ. It much like the bench chisel, but hyper-durable in case of heavy-duty. This chisel is not common any longer, as it is mostly used by boat builders, and nowadays boats are not built by hand.

These types of chisels are suited for major projects that require a little bit of grit, making their edges harder than other types. However, some other chisel alternatives are out there.

It would be better for a woodworker to get the complete set of this chisel, as it is durable and makes work done with ease due to its sharp edge.

Japanese Bench Tools:

The Japanese chisels are very important bench hand tools that offer an accurate cut on softwood. Its blade is thicker, and it is sharpened at the edges, making it excellent at doing its job.

The Japanese chisels look like the ones from the West, but their difference occurs in the blade thickness and sharpness. Another great difference is that the edge of the west chisel is slightly less bevelled.

Mortise Chisel:

The chisel is popularly known in the carpentry world and is used mostly in cabinetry projects. It features a fine edge on either side, looking much like the blade of a knife and a good design wooden handle.

This hand tool made with tempered steel is very durable, as the blade is very hard.

Read about Punch Tools with this detailed guide!

Socket Chisel:

These types of chisels have a wooden piece that fits into the socket of the socket chisel. Because the wood tenon goes deeper into the socket of the chisel as you beat on it, it will continue to crush the wood fibres together, strengthening them over time.

Sash Mortise:

The sash mortise types of chisel are much alike with the previous one I talked about but are used on specific operations. Because this chisel is used for cutting only shallow mortises, it is not that popular. A woodworker should at least invest in one.

They are light mortising chisels that are very easy to handle and are originally used for chopping off shallow mortises that are seen in the mullions and muntins of a wooden window.

Paring Chisels:

The paring chisels are thin and have a sharper edge, used in performing delicate work such as joint creating. It can be used purposely to remove an extremely thin layer of the woodwork from the workpiece.

Tang Chisels

A tip on the tang chisel fits into the chisel handle. A socket chisel would be a better choice if you are going to often strike the tang chisel with a hammer.

This is due to the fact that any striking increases the chance that the chisel tip will penetrate deeper into the wooden handle and eventually lead the handle to break apart.

How to Use a Chisel

When using wood chisels for cutting, it is crucial to present the chisel at the appropriate angle and rely on hand pressure. Use both hands, with the dominant hand on the handle and the other wrapped around or pressing the blade.

Use the heel of your dominant hand for small blows when the full force of a hammer isn’t needed. Wood chisels come in various shapes and sizes, and it is essential to use the correct chisel for the job.

Choose smooth, rectangular handles with no sharp edges attached firmly to the chisel. Check the stock for knots, staples, nails, screws, or other foreign objects before chiselling. Clamp the stock and adjust your stance to avoid losing balance.

Chip or cut with the blade pointing away from yourself, keeping your hands and body behind the cutting edge. Use a wooden or plastic mallet with a large striking face on all chisels, and make finishing or paring cuts with hand pressure alone.

Store chisels in a “storage roll” with slots for each chisel and replace broken or splintered handles. Sharpen cutting edges as often as necessary and wear eye protection if there is a risk of eye injury from particles released from the workpiece or when sharpening.

Related: 14 Types of Woodworking Joints and their Uses

Chisel Tools Material and Sizes

Tool steels, such as A2, O1, and PMV11, are used to measure the hardness and durability of blades. O1 steel is a soft, easy-to-sharpen steel that has been used by many companies for a long time.

A2 steel is harder but more difficult to sharpen, resulting in a longer-wearing edge.

PMV11 steel, developed by Lee Valley Tools, is a medium between O1 and A2 steel, offering a soft, easy-to-sharpen, and incredible durability.

For Americans importing wood from local home centres, two sizes of chisels are needed: a 3/4 inch chisel and a 1/4 inch chisel. The adjoining piece of wood should be 1/3 of the thickness of the main case piece.

Having one chisel the same width as the main piece of wood (3/4 inch) and one the same width as the adjoining piece (1/4 inch) will provide the necessary toolkit for joining two pieces of wood together.

A larger chisel can be helpful for removing a lot of wood, but it is not necessary at the outset.

FAQs

What is a chisel used for?

Chisels are designed to break up materials and remove shavings, making them useful for tasks like cutting, shaping, and carving.

What is the definition of a chisel?

Chisel is a metal tool with a sharpened edge at one end used to chip, carve, or cut into a solid material (such as wood, stone, or metal).

What is the type of chisel?

Wood Chisel: Wood chisels are for carpentry or furniture work. They include bevel-edged, butt, framing, mortise, dovetail, corner, skew, parting, Japanese, carving, and flooring chisels. Metal Chisel: Cold and hot chisels are the two main chisel types that shape and cut metals.