Since their invention, jacks have found extensive applications in various fields for the purpose of lifting large forces or heavy loads. There are different types of jacks out there, although they perform the same operation.

The most commonly used and available ones are mechanical and hydraulic jacks. Mechanical jacks work with screw thread for lifting heavy equipment, while hydraulic jacks use hydraulic power. The automotive industry frequently uses this jack.

In this reading, we will delve into the definition of a hydraulic jack, its various applications, components, diagrams, advantages, disadvantages, and operation.

Let’s begin!

Learn about the best floor jack with this detailed guide!

What Is a Hydraulic Jack?

Hydraulic jacks are mechanical devices used to lift heavy weights. The automobile industry commonly uses them to lift vehicles from the ground, earning them the name “hydraulic car jack”.

Typically, manufacturers rate jacks based on their maximum lifting capacity, such as 1.5 tons or 3 tons. Industrial jacks are capable of supporting loads up to several tons.

Pascal’s law can calculate the force of hydraulic jacks. Hydraulic jacks consist of two pistons inside the cylinder responsible for lifting the heavyweight. We connect the bigger and smaller cylinders together.

The small piston forces the fluid to lift the big piston. Two ball valves work as check valves, allowing flow and stopping it while pumping.

Pressure = Force X Area

Inserting a bar into the jack’s handle socket causes a piston to force the hydraulic fluid through a one-way valve. The fluid force acts at the bottom of the bigger cylinder, allowing the ram to go upwards.

The other valve is blocked, so pressurized fluid can’t get back until it is unscrewed. This is how the hydraulic jack works.

Applications of Hydraulic Jacks

In many industries, jacks serve a variety of purposes, including lifting and transporting heavy loads, relieving the vertical forces on weight-bearing members, and providing space for repairs.

Construction work, shipbuilding, automotive repair, and other specialized industries also employ hydraulic jacks and other types of equipment. Below are the applications of all types of jacks, including hydraulic jacks.

- Aircraft

- Automotive

- Bridges

- Cable tensioning

- House moving

- Construction

- General industrial

- Laboratory

- Locomotive

- Marine

- Mobile home

- Railroad

- Shipbuilding

- Shoring and stabilizing, such as for tunnels and mines

- Tractors & trailers

You should learn about Best Portable Tire Inflators with this detailed guide!

In essence, the applications of hydraulic jacks include

- Lifting heavy industrial loads.

- Lifting cars and vehicles for clamping.

- Finally, clamping machinery equipment.

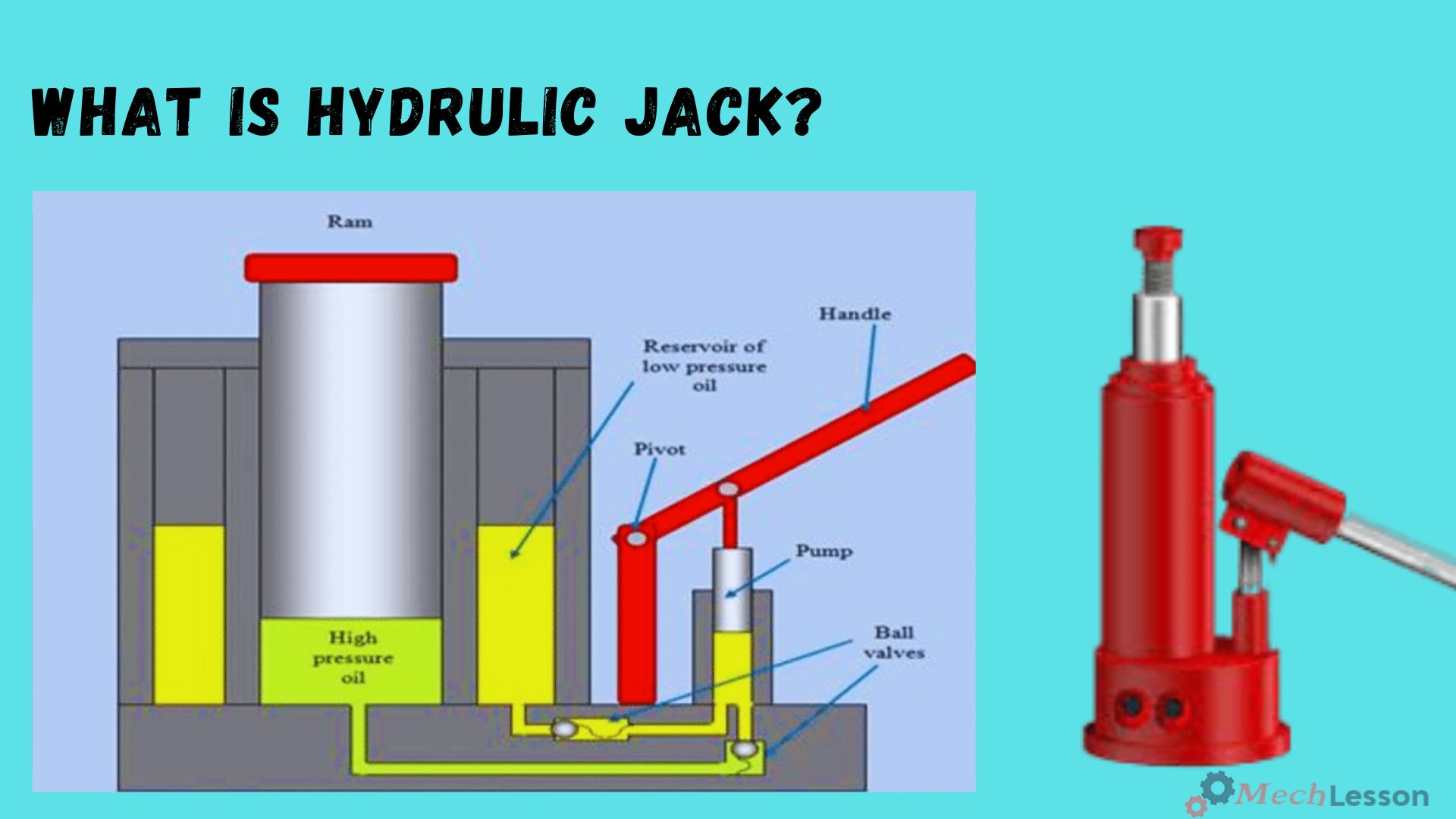

Components of Hydraulic Jacks

To illustrate and understand the components of hydraulic jacks, a typical manually operated hydraulic jack will be considered since it’s commonly used. Below are the major components of hydraulic jacks.

- Reservoir or buffer tank

- Pump with piston or plunger

- Pump lever or handle

- Check valve

- Main cylinder or ram

- Release valve

- Handle

- A reservoir or buffer tank is a vessel that holds the hydraulic fluid or pumps oil, which will be used to transfer applied pressure from the pump to the ram.

- A piston pump is a part that is mechanically activated by moving the pump lever or handle up and down.

- Pump lever or handle: the movement of the pump lever builds up pressure in the hydraulic fluid, which transfers that pressurized fluid through a check valve and into the main cylinder.

- The main cylinder, also referred to as the ram, when driven upwards, extends out of the hydraulic jack body by the pressure of the hydraulic fluid, creating the required lifting force and lifting the load.

- Release valve: a part that helps to release the pressure so that the ram can retract and the load can be lowered.

You learn about the best Lug wrenches with this detailed guide!

Diagram

- Inner Handle

- Outer Handle

- Alligator Clip

- Pins

- Pump Connector Rod

- Link Connector Screw

- Pump Handle Housing

- Pump Rod

- Pump O-Ring

- Pump Plastic Ring

- Pump Housing

- Pump Housing Washer

- Valve Screw

- Valve Screw O-Ring

- Valve Ball Bearing

- Base

- Plastic Bumper

- Plastic Fluid Filter

- Base Plastic Washer

- Ramrod Rubber O-Ring

- Ramrod Plastic O-Ring Retainer

- Ramrod Base

- Ramrod Shell

- Extender Screw

- Inner Chamber

- Outer Cylinder

- Rubber Plug

- Large Plastic Cap Ring

- Outer Cylinder Screw Cap

- English Warnings

- Alternate Language Warnings

You should learn about Best Car Ramps with this detailed guide!

Types of Hydraulic Jacks

The two types of hydraulic jacks include bottle jacks and floor jacks.

Bottle Jacks:

Bottle jacks are also known as hand jacks; they became popular in the early 1900s when the automobile industry began to take off. They are portable and serve a great purpose in enabling individuals to lift vehicles for roadside inspection or service.

The design of the bottle jack resembles a milk bottle, hence its name. Today’s bottle jacks have the capability of lifting from one hundred pounds to several tons, although they range in size.

Floor jacks:

Floor jacks operate horizontally, in contrast to the vertical operation of bottle jack shafts. The shaft exerts pressure on a crank that links to a vertically raised lifting pad.

These types of hydraulic jacks provide a greater range of vertical lift than bottle jacks and are available in two sizes. The conventional size is about four feet long and a foot wide and weighs around 200 pounds.

They can lift about 4–10 tons. Later, they created a more compact model that can lift 11/12 tons and measures about three feet in length. Additionally, there exist mini-jacks that defy standard floor jack classifications.

Note: Hand power, compressed air, electric power, or gas can operate hydraulic jacks.

Other types of jacks include

Toe Lift Hydraulic Jacks:

The toe lift hydraulic jacks are special types used to lift machinery and other loads that have low clearance between the ground and the bottom surface of the load. This special jack works in situations where the bottle jack or floor jack can’t work due to the low ground clearance of the load.

Leveling Jacks:

These types of jacks make use of mechanical screw mechanisms. They are portable and often used to level trailers, RVs, etc.

Scissor Jacks:

Scissor jacks are compact jacks that use a mechanical screw. The screw rotation results in the raising and lowering of a set of scissoring arms that extend or retract depending on the position of the screw mechanism.

Screw Jacks:

Screw jacks are mechanical jacks that use a vertical screw mechanism to lift and lower the load. Some are designed to be wrench adjustable, while others make use of a level inserted through a hole in the jack. This allows additional mechanical advantage when turning the screw to lift the load.

Ratchet Jacks:

These types of jacks make use of a pawl and ratchet mechanism for raising or lifting a load. At a point in time, ratchet jacks were the standard types of jacks automobile manufacturers included with their vehicles for owners to use for changing flat tires.

You should learn the Best Engine Degreaser with this detailed guide!

How Does a Hydraulic Jack Work?

Hydraulic jacks operate in a less complex and easily understandable manner. The type of jack that was previously explained is the bottle type. The jacks work based on Pascal’s Principle.

It states that pressure applied to a confined fluid is transmitted uniformly in all directions. This principle helps us understand that a small force is applied to a smaller area to lift a heavy load on a larger area.

In its working, the pump handle is used to apply force, while the hydraulic cylinder carries the fluid and pistons. A small piston, which is known as the pump piston, is used to generate pressure by moving hydraulic fluid.

The large piston lifts the load, and a check valve is used to prevent the fluid from flowing back to the reservoir.

How to Use a Hydraulic Jack?

The following are the right ways of using a hydraulic jack:

1. Pumping the Handle

The user moves the hand up and down to activate the pump piston. This motion pushes the hydraulic fluid in the reservoir into the cylinder through a check valve.

2. Generating Pressure

As the fluid enters the hydraulic cylinder, pressure builds up because of the incompressible nature of the fluid. The pressure, which is equally distributed across the hydraulic system,

3. Load Lifting

The system’s built-in pressure then drives the large piston, also known as the load piston, upwards. The system then lifts the intended heavy load. The small piston amplifies the applied force, enabling the jack to lift significantly heavier loads than the input force.

4. Maintaining the Load

Use the check valve effectively to stop the fluid from flowing back. This ensures the piston holds its position and keeps the load lifted.

5. Lowering the Jack

To bring the piston back downward, you loosen the pressure via the release valve. The causes the hydraulic fluid to flow back to the reservoir, causing the large piston to retract, which then lowers the load.

You should learn about The Best Pry Bar with this detailed guide!

Advantages and Disadvantages of Hydraulic Jacks

Advantages:

Below are the benefits of hydraulic jacks in their various applications.

- Most designs occupy less space.

- Less likely to jam due to rust in the screw thread.

- Highly effective with heavy loads.

- It is easier to use.

- Loads are lifted with minimum effort.

- It is lighter than screw jacks.

Disadvantages:

- It has a relatively low speed.

- Susceptible to failure if oil seals are worn out.

- The device can emit an unpleasant odor due to the overuse of warm oil.

- Overheating can quickly occur.

- The leakage of hydraulic oil can cause soil and water pollution.

Conclusion

Hydraulic jacks are mechanical devices used to lift weights. The automobile industry commonly uses them to lift vehicles from the ground, earning them the name “hydraulic car jack.” The force of hydraulic jacks can be calculated with Pascal’s law.

A hydraulic jack is a powerful and compact lifting device that uses hydraulic pressure to lift heavy loads with minimal effort. It operates on Pascal’s Law, where pressure applied to a confined fluid is transmitted equally in all directions.

Widely used in automotive, construction, and industrial applications, hydraulic jacks are essential tools for lifting vehicles, machinery, and heavy equipment safely. Understanding how they work and maintaining them properly ensures long-term performance and user safety.

You should learn How To Become a Mechanic with this detailed guide!

Frequently Asked Questions (FAQs)

How does a hydraulic jack work?

It works by applying force to a small piston, which pressurizes hydraulic fluid. This pressure is transferred to a larger piston, lifting the load.

What types of hydraulic jacks are there?

- Bottle Jack: Vertical and compact, used for cars and heavy lifting.

- Floor Jack: Horizontal design, ideal for car repair shops.

- Scissor Jack (Hydraulic): Uses hydraulic action in a scissor framework.

What fluid is used in hydraulic jacks?

Most use hydraulic oil, which is specially formulated for high pressure and stability.

How much weight can a hydraulic jack lift?

This depends on the jack’s rating. Common household jacks lift 2 to 20 tons, while industrial jacks can lift even more.

Why is my hydraulic jack not lifting?

Common reasons include low fluid levels, air in the system, or worn seals. Bleeding the jack and refilling the fluid often fixes the issue.

Is it safe to work under a car supported only by a hydraulic jack?

No. Always use jack stands for safety after lifting the car with a jack.

How often should I check the hydraulic fluid?

Check it regularly, especially before use. Refill and replace the fluid as needed to maintain efficiency.