An automobile engine is a positive displacement internal combustion engine with an intake, compression, combustion, and exhaust stroke. Its main job is to transform energy from fuel into working power. In other words, it produces the power that makes the car move.

The engine is the heart of your car. It is a complex machine that converts heat from burning gas into the force that turns the road wheels. In the reading, we’ll explore the common parts of a car engine.

Let’s get started!

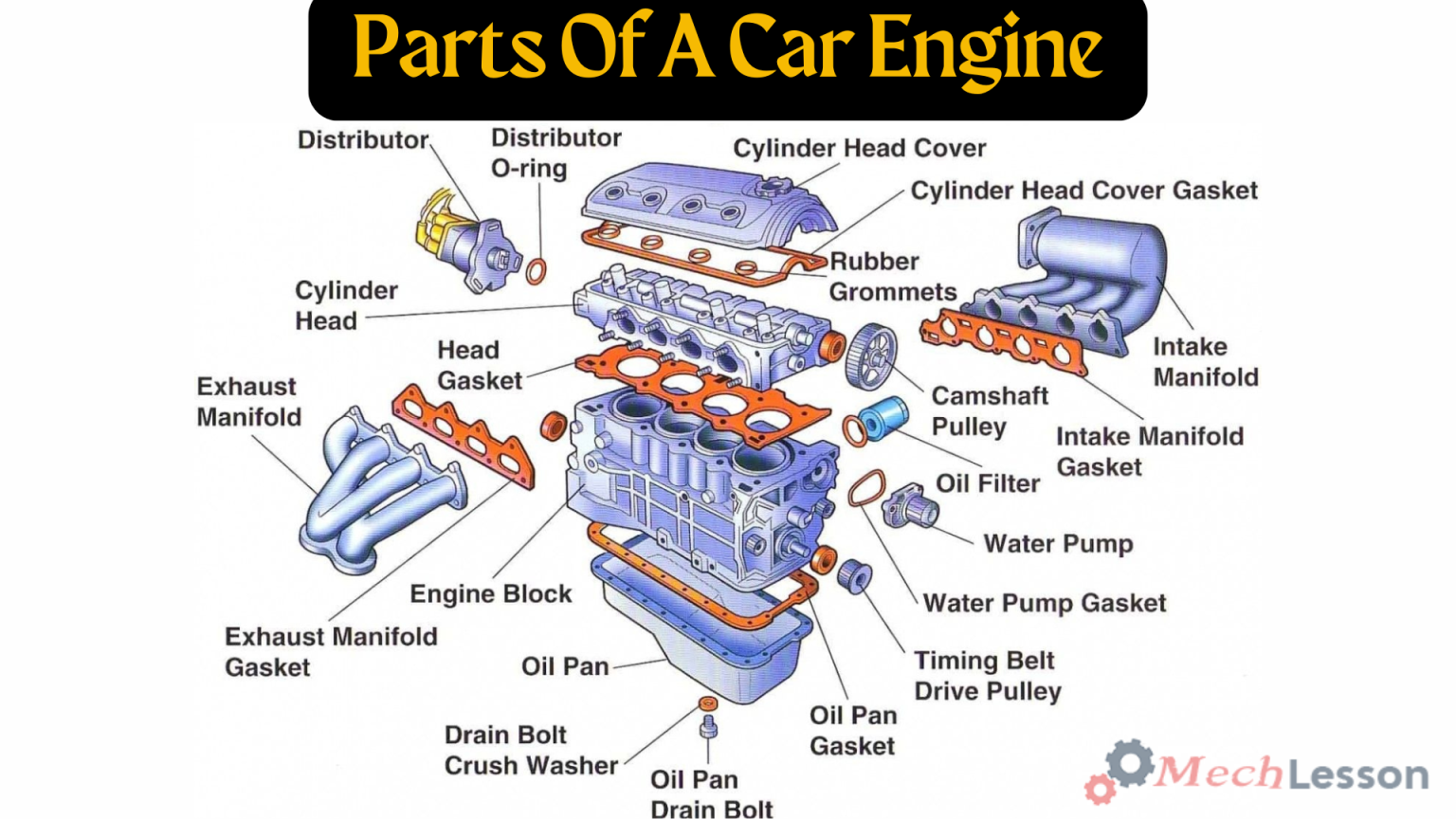

Parts of a Car Engine

Understanding the parts of a car engine is essential for grasping how vehicles operate. Here’s an overview of the key components:

Engine or Cylinder Block

The fundamental structure of the engine is the cylinder block or engine block, which is a significant component of engine parts. The three components that make up the engine’s cylinder block, cylinder head, and crankcase serve as its structure and major stationary body.

Piston

Pistons are the most important engine component compared to other parts. The piston is a cylindrical plug that rotates inside a cylinder. Engines with a piston velocity of 1250 RPM will rise and fall 2500 times per minute.

Cylinder Head

Cast iron and an aluminum alloy are typically used to create the cylinder head. Studs mounted to the block connect the cylinder head and block, providing a tight, leak-proof connection through the use of gaskets. Above each cylinder, the cylinder head contains a combustion chamber.

Cylinder Cover

Cast iron or an aluminum alloy typically make up a cylinder head cover, which seals the cylinder head. This is due to the superior heat-draining properties of aluminum alloy compared to other metals. In an internal combustion engine, the cylinder head/cover covers the combustion chamber, making it a closed area where the combustion can happen.

Crankshaft

The crankshaft is the part of the engine that draws power. All engine parts use it as one of their primary sources of power transmission. The main component of the power transmission system where the piston’s reciprocating motion is turned into a rotational motion with the aid of a connecting rod is the crankshaft.

Camshaft

A camshaft is a shaft that has cams installed on it. A cam is a piece of equipment that converts the camshaft’s rotating motion into the follower’s linear motion. The movement of a camshaft opens the valves. This part of the car’s engine has several cams, two for each cylinder, one for the inlet valve, and one for the exhaust valve.

Cam

In a mechanical linkage, a cam is a rotating or sliding component that converts rotary motion into linear motion. This cam is responsible for converting the rotary motion of the camshaft into the linear motion of the valves. The camshaft is a shaft that has several cams attached to it. It also regulates the timing for opening and closing the valve.

Crankcase

The fuel/air mixture often passes through the crankcase before entering the cylinder in two-stroke engines, which typically employ a crankcase-compression arrangement. The design of this engine does not include an oil sump in the crankcase. The majority of the oil in four-stroke engines is stored inside the crankcase, which normally has an oil sump at the bottom.

Timing Belt

To synchronize the rotation of the crankshaft and camshaft in a piston engine, either a timing belt (also known as a cambelt), a timing chain, or a set of timing gears is employed. In addition, the timing belt or chain in an interference engine is essential for avoiding piston-valve contact. Typically, a timing belt is a drive belt with teeth on its inner side.

Engine Valves

Engine valves are necessary to regulate the timing of the entry of the air-fuel mixture into the cylinder and the exit of the combustion products from the cylinders. These are situated at the engine’s inlet and outlet openings. When closed, the valves are snug against the valve seats.

Intake and Exhaust Valves

Inlet and exhaust valves, respectively, control and regulate the charge (or air) entering the engine for burning and the exhaust gases exiting the cylinder. The entrance valve is where the air and fuel combination enters petrol engines. Diesel engines’ intake valves, meanwhile, can only let air in. The exhaust valve’s goal in either scenario is to let exhaust gases out.

Valvetrain

The governor is the component that controls the movement of the valves. It is attached to the cylinder head. It is comprised of the rocker arms, pushrods, lifters, and valves.

Throttle Body

In response to driver input, the throttle body modifies the opening size of the throttle to manage the engine’s power output and RPMs.

Air Intake System

The engine receives clean air from an air filter and ducts that direct it into the intake manifold. The throttle body controls engine airflow and performance.

Fuel injectors

Fuel is essential for the combustion process. There are three types of fuel injection systems: direct fuel injection, port fuel injection, and throttle body fuel injection. Fuel injectors deliver fuel to the cylinders.

Pushrods/lifters

Camshaft lobes do not contact rocker arms in overhead valve engines. Instead, pushrods or lifters are employed within the valve system to facilitate this interaction.

The Rocker Arms

The rocker arms interact with the cams to push down on the valve system, allowing the necessary air to enter the chamber or the exhaust to exit.

Oil Pan

The oil pan, or sump, is the term for the lower section of the crankcase. The crankcase secures the oil pan with set screws, while a gasket seals the interface to prevent leaks. When changing the oil, a drain plug is placed at the bottom of the oil sump to allow the dirty oil to drain away. The sump is often made of a cast aluminum alloy or pressed steel sheet.

Spark Plug

Spark plugs are essential components in the engine, igniting air and fuel to initiate combustion. In modern engines, the ignition coil produces high-voltage electricity, which the spark plug converts into a spark. The spark is produced in the combustion chamber, igniting the air-fuel mixture before the power stroke.

An electrically insulated ceramic insulator separates the threaded metal sleeve from the central electrode of the spark plug. The center electrode, which may include a resistor, is connected to the output terminal of an ignition coil or magneto by a tightly insulated wire.

The metal housing of the spark plug is grounded electrically, which guarantees optimal performance. A spark gap forms between the tip of the center electrode and the side ground electrode when the center electrode goes through the porcelain insulator and into the combustion chamber.

Combustion Chamber

The region of the cylinder where the fuel/air mixture ignites is known as a combustion chamber. The piston compresses the air-fuel mixture, which ignites upon exposure to the spark plug, converting it into mechanical energy as it exits the combustion chamber.

The injector nozzle, piston, spark plug, combustion chamber, and other significant internal combustion engine components are all housed in the cylinder.

Manifold

Manifolds are separate sets of pipes that connect to the cylinder head and carry the air-fuel mixture and exhaust gases. Cast iron typically forms the manifold to withstand the high temperature of exhaust gases. It comprises the carburetor flange, intake manifold flange for the tailpipe, throttle body flange, and air intake flange.

Intake Manifold

The intake manifold in an automobile divides airflow between the cylinders and houses the throttle valve and other components. In some V6 and V8 engines, the intake manifold can have multiple sections.

The intake air passes through the air filter, intake boot, throttle body, intake manifold plenum, runners, and cylinders before entering the engine. The throttle valve regulates the engine’s rpm by controlling the airflow.

Exhaust Manifold

The exhaust manifold, which collects engine exhaust gas from several cylinders and sends it to the exhaust pipe, is often a straightforward cast iron or stainless-steel unit. It’s linked to the exhaust valves. Its design is identical to that of the inlet manifold. The exhaust manifold serves the same purpose in diesel and gasoline engines, transporting exhaust gas in either case.

Spark Plugs

In internal combustion engines, a spark plug is an electrical component that uses an electric spark to ignite compressed aerosol fuel. The use of the electrical component in mechanical tasks is important.

A spark plug ignites the compressed fuel/air mixture with an electric spark and maintains engine combustion pressure by transferring electric current from an ignition system to the combustion chamber of a spark-ignition engine.

Connecting Rod

The connecting rod’s primary job is to change the piston’s reciprocating motion into the crankshaft’s rotating motion. To endure pressure and twisting forces, it must be light and strong enough. Typically, drop forging produces the connecting rod from alloy steel or duralumin, resulting in an I-beam cross-section. These days, it is also cast from spheroidal or malleable graphite C.I.

Water Pump

The water pump in a car is a belt-driven device that receives power from the engine’s crankshaft. The water pump pulls the cooled fluid from the radiator through the pump’s center inlet and is constructed as a centrifuge. The water pump circulates the fluid outward into the engine before returning it to the car’s cooling system.

Timing Belt Drive Pulley

An exclusive type of pulley system with teeth or pockets along the outside of the pulley body’s diameter is a timing belt pulley. The teeth or outside pockets of the pulley do not transmit power. Instead, they activate the pulley belt to aid timing and prevent misalignment.

Oil Pan Drain Bolt

Usually, the oil drain plug is located on the oil pan at the engine’s base. You use it to drain the oil from your pan during an oil change. In some instances, replacing the gasket is all that is required to fix an oil plug leak. A new oil drain stopper can be necessary if the bolt or oil pan has been cross-threaded. To assist you in avoiding replacing the entire oil pan, a large oil drain plug may occasionally cut fresh threads.

Piston Ring

Steam or internal combustion engines insert piston rings into the piston’s grooves to form a strong seal with the cylinder wall. The piston’s outside diameter is connected to a metallic split ring called a piston ring.

In older designs, there were 2-4 compression rings and 1-2 oil control rings per piston, while recent designs typically have 3-1 compression rings and 1 oil control ring per piston.

The piston ring seals high-pressure gases from the combustion chamber from entering the crankcase, allowing heat transfer from the piston crown to the cylinder walls. It also ensures sufficient lubrication fluid on the cylinder walls during the piston’s travel, reducing cylinder wear. In engines, piston rings serve the following primary purposes:

- We are sealing the combustion chamber to reduce gas leakage into the crankcase.

- The focus is on improving the piston-to-cylinder wall heat transfer.

- It is important to ensure that there is the right amount of oil between the piston and the cylinder wall.

- By returning scrap oil to the sump, we can limit the amount of engine oil used.

Flywheels

A flywheel is a mechanical device that keeps energy from spinning, which depends on how heavy it is and how fast it’s spinning, following the rule that angular momentum stays the same. The engine produces torque, but it is not constant and fluctuates.

Cylinder Liner

To prevent the issue of cylinder wear, these cylindrical shapes are used in the cylinders. It is one of the most crucial structural components that make up an engine’s interior. You can replace these when they wear out.

An iron alloy containing silicon, manganese, nickel, and chromium constructs them. These are typically centrifugally cast. These liners are corrosion- and wear-resistant.

Distributor

The distributor in internal combustion engines with spark ignition and mechanically timed ignition is an enclosed rotating shaft responsible for delivering high-voltage current from the ignition coil to the spark plugs in the correct firing sequence and duration.

Camshaft Pulley

An engine’s timing system uses a cam pulley to regulate the camshaft’s rate of rotation, which in turn regulates the poppet valves that control air intake and exhaust in the cylinders. The timing chain and cam pulley work together to synchronize crankshaft and camshaft rotation.

Oil Filter

To keep the engine in your automobile operating smoothly, it filters the motor oil to remove dangerous dirt, metal shavings, and debris. Without an oil filter, dangerous contaminants could enter your motor oil and ruin the engine. Your engine oil will stay cleaner and last longer if you filter out the trash.

Gudgeon Pin

In the United States, we refer to an internal combustion engine part that connects the piston to the connecting rod as a gudgeon pin or wrist pin. As the piston moves, it offers a bearing for the connecting rod to pivot on.

The piston pin is often a forged short hollow rod of high-strength, high-hardness alloy steel that may be physically separated from the connecting rod, piston, and crosshead. In the piston, a circular saw secures the chamfered pin ends, while the small-bore end of the connecting rod encircles it from the center.

Fuel Delivery System

The fuel delivery system regulates the amount of gasoline that is delivered to the engine in order to mix it with the air that is flowing in. It consists of parts such as the fuel tank, fuel injectors, and fuel pump.

Fuel injectors are responsible for spraying fuel into the intake manifold in a precise manner, where it is then mixed with the air that is coming in. Before ignition, cylinders compress this mixture.

Rubber Grommet

The purpose of an automotive grommet is to stop water from getting through a hole drilled in an engine body or other equipment and to shield electrical wires, tubes, or hoses from physical damage. The grommet is a round rubber object.

Grommets serve as an accessory for wiring devices, allowing wires to pass through the center of the hole. This component’s function is to protect the wire from the cutting edges of sharp sheet metal. Additionally, it is resistant to dust and water.

Distributor O Ring

A round rubber ring serves as the distributor O-ring. Timing must be perfect because the distributor “tells” the spark plugs when to fire. When a distributor moves out of place, it can mess up the speed and hurt the engine.

Distributor O-rings are straightforward; they prevent oil leaks, misfires, and power loss by sealing the distributor housing to the engine. Other problems may happen if the O-ring breaks and oil leaks appear at the base of the manifold.

Cooling System

The cooling system keeps the engine temperature under control with the mixture of water and coolant. The water pump moves coolant around the engine and radiator, where it cools down and releases the heat into the air. A thermostat helps keep the engine at the right temperature so it works well and lasts a long time.

Lubrication System

One of the key functions of the lubrication system is to reduce the amount of friction and wear that occurs between moving parts. It uses engine oil, an oil pump, and a system of tubes to get oil to different parts of the engine. Without the appropriate amount of lubrication, the moving parts of the engine would grind against each other, which would result in substantial damage.

Supercharger and Turbocharger

The purpose of both devices is to compress the air that enters an engine to boost the engine’s power output. To generate more power, the compressed air makes it possible to burn more fuel. Their respective powers are the key difference between the two.

To power a turbine, which in turn powers a small compressor or impeller, which in turn crams more air back into the engine, a turbocharger makes use of the velocity and heat energy of the hot exhaust gasses that are emitted from the cylinders of an engine.

An electric motor or the engine itself, by a belt that runs off the crankshaft, powers a supercharger, which likewise feeds more air into the engine.