A propeller shaft is a component in automobile engines that transfers power from the gearbox to the differential. It is also used in a boat and a flying machine. The shaft is also known as a driveshaft, driving shaft, tail shaft, or even Cardan shaft. In this reading, we’ll explore what a propeller shaft is, its diagram, parts, types, and how it works.

Let’s get started!

You should learn about Differential with this detailed guide!

What Is A Propeller Shaft?

A driveshaft, often referred to as a propeller shaft or prop shaft, is an essential part of a car’s drivetrain and is mainly used in four-wheel and rear-wheel drive systems. Its primary job is to transfer torque, or rotational power, from the engine to the differential, which allocates the power to the wheels so that the car may drive.

Through the transmission and differential, the driveshaft serves as a conduit, joining the engine to the wheels. Usually composed of steel or aluminum, it is a long, cylindrical metal shaft that is intended to tolerate severe torque and vibration.

The load-bearing is equivalent to the difference between the input torque and the load. A propeller shaft in a vehicle relies on several supportive components. These components include universal joints, jaw couplings, or rag joints.

Since four-wheel drive (4WD) and rear-wheel drive (RWD) systems depend on a separate differential to control power distribution to the wheels, driveshafts are crucial components of these vehicles.

In order to adapt to suspension movement and shifts in the angle between the gearbox and the differential, the driveshaft frequently has universal joints or other flexible systems. This ensures that power is transmitted efficiently even when the vehicle is traveling over rough terrain.

Learn about Flywheel with this detailed guide!

Functions

The function of a Propeller shafts is to transmit torque and rotation. It’s used to connect other components and drive trains that cannot be connected due to distance.

A driveshaft is also widely used in marine, aviation, etc. for the same purpose. The shaft must be strong enough to bear the stress as it experiences torsion and shear stress during the transmission.

All-wheel drive (AWD), front-engine configurations, and rear-wheel drive (RWD) cars all depend heavily on the driveshaft’s function in the transmission of power and torque.

In these setups, the driveshaft is in charge of sending power from the front-mounted engine to the back wheels, or all four wheels in the case of an AWD vehicle.

The engine’s power cannot adequately reach the wheels without a functional driveshaft, which results in diminished performance, poor fuel efficiency, and even problematic driving.

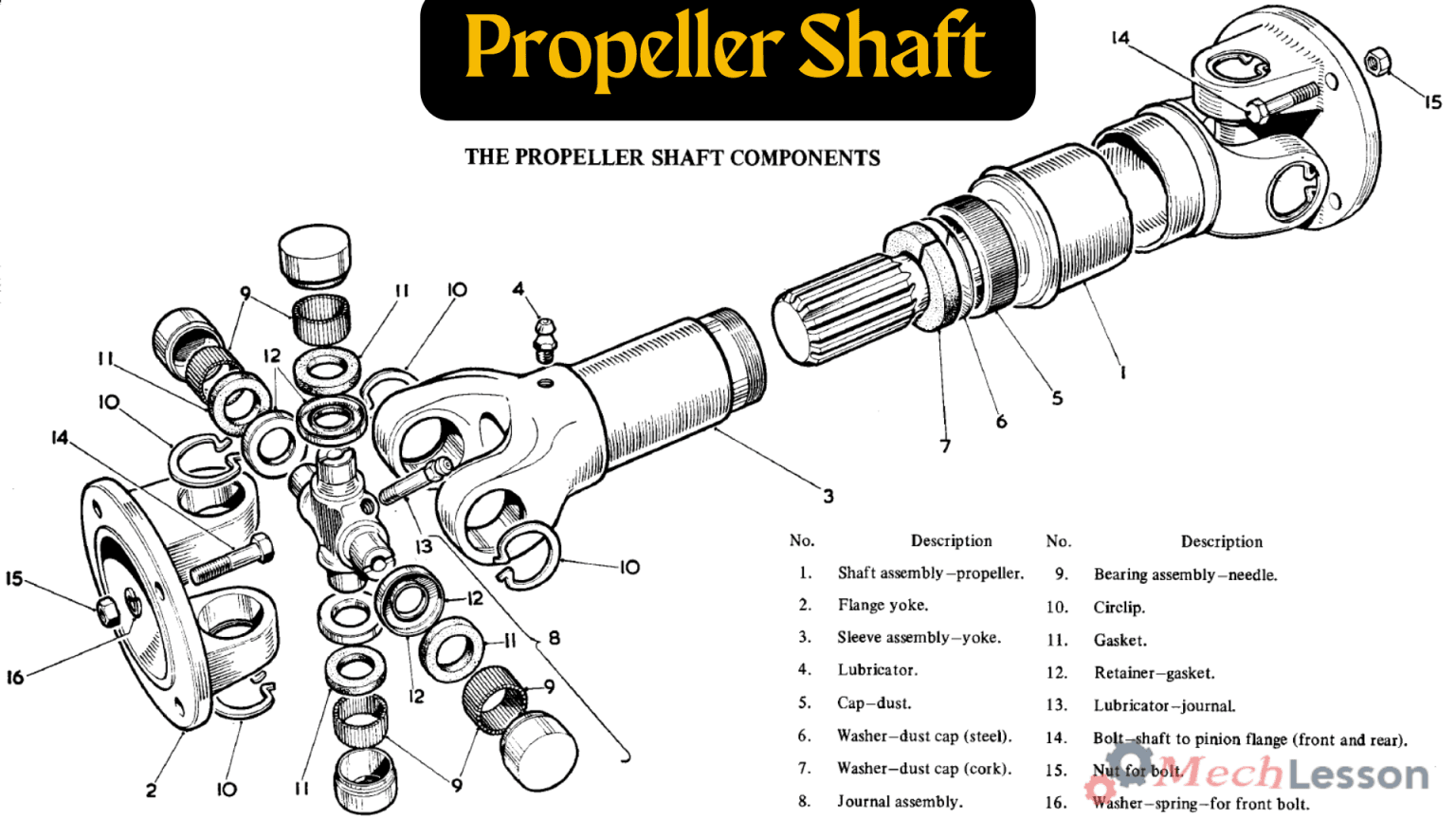

Major Parts Of The Propeller Shaft

Below are the parts of the propeller shaft:

- Universal joints: the function of this part is to transfer the engine’s torque to the rear axle.

- Splines: the splines are located at the ends of the shaft in the sleeve. Its function is to permit the length variation between the driving and the driven unit to vary slightly. It also prevents the input and output bearings from being damaged.

- Flange: it serves as support for the propeller shaft and gearbox joint.

- The main bearing also supports and guides the propeller shaft.

Diagram Of A Propeller Shaft

You should learn about Axle with this detailed guide!

Types Of Driveshafts

In a vehicle, a longitudinal shaft is used to deliver power from the engine or transmission to the other end of the vehicle.

A pair of short drive shafts are commonly used to send power to some other component before reaching the wheel. Below are the various drive shafts used in an automobile engine:

Single-Piece Shaft

This is used in a vehicle with a short distance between the engine and axles. Usually four-wheel-drive vehicles. Friction welding is done at the junction to improve the strength, quality, and durability of the junction.

Two-Piece/Three-Piece Propeller Shaft

This is used in vehicles with a long distance between the engine and axles. The sectioning of the propeller shaft into two or three parts allows the critical number of revolutions to reduce or prevent vibration issues from occurring.

Driveshaft’s Designs and Types

Driveshafts are available in a variety of kinds and designs, each one suited to the unique requirements and features of distinct vehicles. The technical principles that guided its creation include finding the ideal balance between strength, flexibility, and durability.

Let’s examine a few prevalent driveshaft varieties and the engineering ideas behind their creation:

Solid Driveshafts:

Rear-wheel drive cars frequently use solid driveshafts, also referred to as propeller shafts or one-piece driveshafts. These shafts are formed of one rigid tube, often made of steel or aluminum. Solid driveshafts are designed with the goal of conserving weight while optimizing strength and torsional stiffness.

Manufacturers may create a lightweight design that reduces energy loss due to flexing or bending and ensures effective power transmission by utilizing materials with excellent strength-to-weight ratios.

Tubular Driveshafts:

Tubular driveshafts are an improvement over solid driveshafts in terms of weight savings and torsional strength. They have a hollow, cylinder shape and are often composed of steel or an alloy of steel and aluminum.

The idea behind tubular driveshafts is to optimize the material qualities, wall thickness, and tube diameter to increase strength while lowering weight. The driveshaft’s moment of inertia is efficiently reduced by the hollow construction, which enhances acceleration and overall drivetrain responsiveness.

You should also learn the Causes, Symptoms and Maintenance of a Driveshaft with this detailed guide!

Carbon Fiber Driveshafts:

Driveshafts made of carbon fiber are the strongest, lightest, and most effective driveshafts available today. These driveshafts are made of carbon fiber-reinforced polymer composites, which combine lightweight resin with high-strength carbon fibers.

Carbon fiber driveshafts are designed with an emphasis on increasing strength and rigidity and minimizing rotational inertia. Because of the outstanding strength-to-weight ratio of carbon fiber, it is possible to reduce weight by a substantial amount while retaining structural integrity.

This improves acceleration, lowers drivetrain vibration, and increases fuel economy.

CV-Jointed Driveshafts:

Vehicles with front-wheel drive frequently employ constant velocity (CV) jointed driveshafts, as do certain all-wheel drive and independent suspension systems. The idea of CV joints is to adapt to the different rotational velocities and angles that front-wheel drive systems experience.

Even at acute angles, the driveshaft may flex and bend thanks to the smooth torque transmission provided by the CV joints. In order to reduce power loss and provide a smooth power supply to the wheels during steering motions, these joints maintain a consistent velocity.

Flexible Driveshafts:

When the drivetrain components are not arranged in a straight line, flexible driveshafts—also referred to as torque tubes or torque rods—are used. To correct misalignments, these shafts have flexible couplings or universal joints at each end.

Flexible driveshafts are designed to be as flexible as possible while yet having enough torsional strength. Power transmission is made possible by flexible driveshafts in circumstances where a stiff shaft would have alignment problems, such as in complicated drivetrain arrangements or automobiles with independent suspension systems.

Engineering concepts that strive to provide the best power transmission, strength, and flexibility are utilized to govern the design and kinds of driveshafts used in different types of vehicles.

Each kind, from sophisticated carbon fiber constructions to solid and tubular designs, is meticulously built to strike a balance between weight reduction, torsional strength, and drivetrain performance.

Driveshafts serve a critical role in providing effective power delivery and dependable functioning of the vehicle’s powertrain system by using materials and designs that reduce energy loss, improve structural integrity, and handle various angles

You should learn about Transmission System with this detailed guide!

How A Propeller Shaft Works

The propeller shaft rotates in response to the car’s motion. The shaft then goes up and down based on road conditions, whether the road is level or not. As the car goes over uneven ground, the propeller shaft rotates up and down.

A change in shaft length occurs when the propeller shaft moves up and down. This adjustment helps to maintain the car’s transmission system’s distance so that it keeps operating as intended. So, the driveshaft has a universal joint built in to keep the distance and make sure it doesn’t affect any other parts.

Within a vehicle’s drivetrain system, the driveshaft has a key place. It is in charge of transferring torque and power from the engine to the wheels so that the car can move. The driveshaft links the transmission or gearbox at one end to the differential at the other end and is often placed below the chassis.

The driveshaft takes rotational power from the engine and passes it on to the differential after passing through the transmission. The differential further distributes power to the wheels so that they can turn with various rotational velocities. This shows how crucial the driveshaft is for transmitting power and torque.

The driveshaft ensures a strong connection between these two essential parts, allowing power to move without interruption or loss. This efficient transmission of power and torque helps the car move forward, enabling acceleration, maintaining speed, and navigating challenging driving situations like hills or uneven terrain.

Conclusion

The propeller shaft, also known as the drive shaft, plays a vital role in the transmission of torque from the engine to the wheels, especially in rear-wheel and four-wheel drive vehicles.

It must be strong, lightweight, and precisely balanced to ensure smooth power delivery with minimal vibration. A well-functioning propeller shaft ensures efficient drivetrain performance, driver comfort, and longer vehicle lifespan.

Learn about Crankshaft with this detailed guide!

Frequently Asked Questions (FAQs)

What is a propeller shaft?

A propeller shaft is a mechanical component that transmits rotational power from the transmission to the differential in a vehicle.

Where is the propeller shaft located?

It is located under the vehicle, connecting the gearbox (transmission) to the rear axle differential, typically in rear-wheel and four-wheel drive systems.

What materials are used for making propeller shafts?

Common materials include

- Steel (most common)

- Aluminum (lightweight applications)

- Carbon fiber (high-performance vehicles)

What are the parts of a propeller shaft?

- Tube (shaft)

- Universal joints (U-joints)

- Slip yoke or sliding joint

- Center support bearing (in multi-piece shafts)

What are the types of propeller shafts?

- Single-piece shaft

- Two-piece shaft

- Three-piece shaft

What are the common problems in propeller shafts?

- Vibrations during driving

- Clunking noises

- U-joint wear or failure

- Imbalance or bending

How is a propeller shaft maintained?

- Regular inspection of U-joints

- Greasing the joints (if applicable)

- Checking for bends, dents, or imbalance

What happens if the propeller shaft fails?

A failed shaft can lead to loss of power to the wheels, severe vibrations, or complete drivetrain failure, possibly causing unsafe driving conditions.