An ingenious invention that was created more than 200 years ago, a hydraulic ram can push water uphill using only the water flowing into it as an external power source.

The fundamental concept of a ram pump is straightforward. A comparatively little amount of water is pumped upward by the pump using the momentum of a relatively large volume of flowing water.

Well, in this reading, we explore what a hydraulic ram pump is, its functions, its diagram, and how its works. We also discussed its advantages and disadvantages.

Let’s begin!

Learn about Self-Priming Pump with this detailed guide!

What is a Hydraulic Ram Pump?

A hydraulic ram, often known as a hydram, is a hydropower-driven cyclical water pump. It receives water with a flow rate and “hydraulic head” (pressure) and returns water with a lower flow rate and a greater hydraulic head.

A portion of the incoming water that powers the pump may be lifted above its initial level thanks to the device’s usage of the water hammer effect to create pressure.

You need a water supply above the ram pump to operate it. To find the pump beneath the pond, for instance, you need to have a pond on a hillside. From the pond to the pump, a pipe is run. A valve on the pump permits water to pass through this pipe and increase velocity.

In distant locations with a low-head hydropower source and the requirement to pump water to a location higher than the source, the hydraulic ram is occasionally employed. The ram is frequently helpful in this circumstance since it just requires the kinetic energy of flowing water and no other energy source.

A town may get about 20,000 liters of water each day—enough to fill 250 baths—from a single hydram, which can elevate water up to 200 vertical meters. They may be made mostly of sturdy materials like steel. It also implies that they may be built and fixed with common, repurposed materials.

Functions of a Hydraulic Ram Pump

Hydraulic ram pumps utilize pressure generated by a “water hammer” shock wave, which is a result of the inertia of water in a pipe. This inertia resists sudden changes in velocity, and slowly closing a valve allows this inertia to dissipate over time, producing minimal pressure increase in the pipe.

Rapidly closing a valve creates a pressure surge or shock wave as the flowing water stops, moving back up the pipe. The larger the shock wave produced, the more quickly the valve is closed.

Faster water flow and longer pipes also contribute to the larger shock wave. A hydraulic ram pump operates by utilizing a non-pressurized flow of water in a “drive” pipe from a water source to the pump.

This flow is produced by placing the hydraulic ram below a water source and running the drive pipe from the water source to the pump. The pump employs two check valves, the only moving parts, to maintain the pressure.

Hydrams are special because of their ease of use, robustness, and almost cost-free operation. Because the water they supply is what powers them, they are reasonably priced. Because they are made up of just two moving parts—a supply valve and a waste valve—they are straightforward.

Learn about Dynamic Pump with this detailed guide!

Parts of Hydraulic Ram Pump

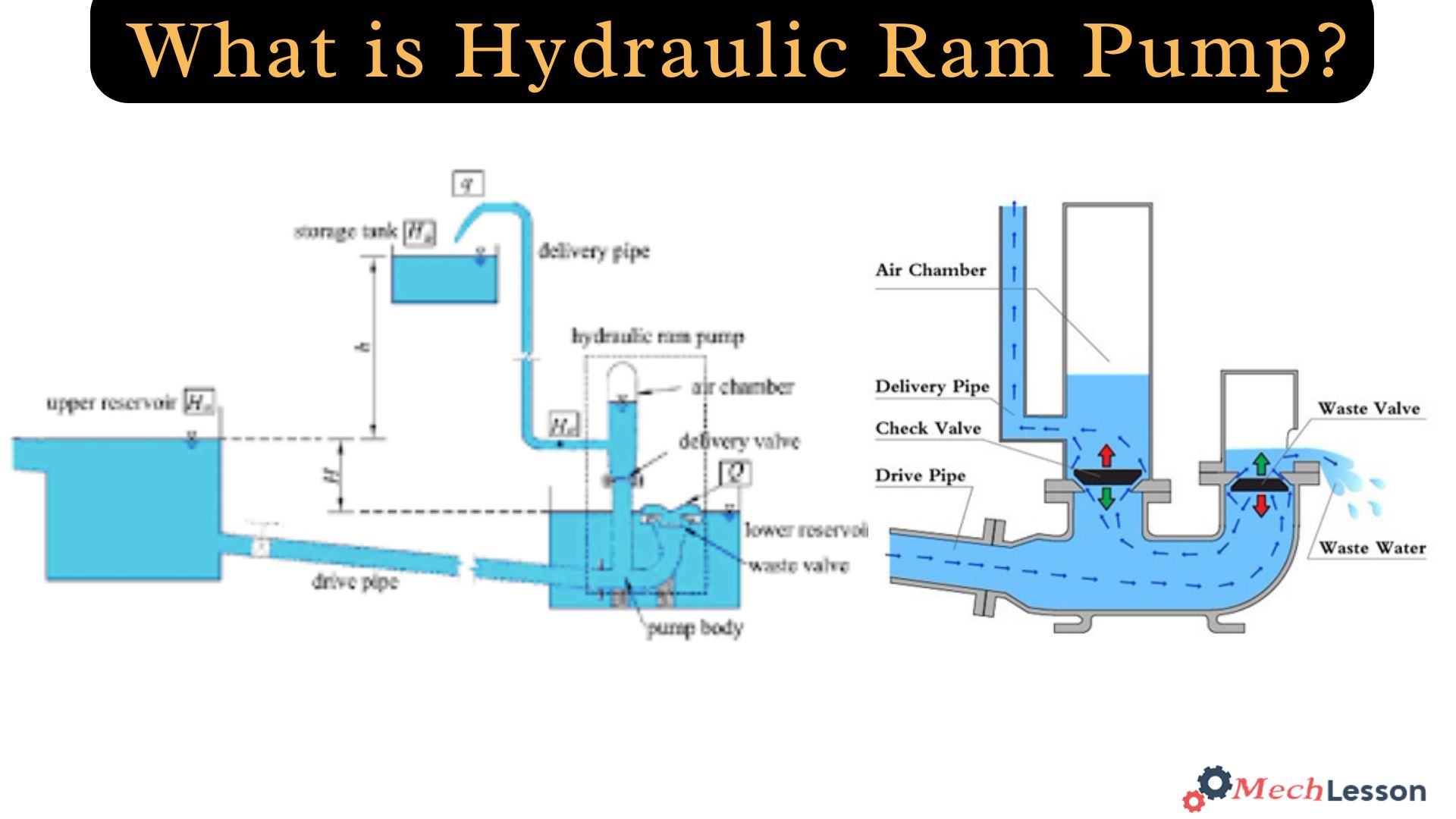

The header tank, the pump, and the connected pipework are the three primary components of the device. An appropriate wall is where the header tank is mounted. The pump possesses a delivery portion, an air vessel to lessen hydraulic shock, and a supply line with inner and outer valves.

Diagram

Learn about Pump with this detailed guide!

How Does a Hydraulic Ram Pump Work?

Water is pumped from its source to a community via the hydraulic ram pump, often known as a hydram. Because it harnesses the natural force of falling or swiftly flowing water, the hydram doesn’t need any outside energy to run.

This procedure operates on the “water hammer” concept, which creates pressure by forcing a lot of swiftly flowing water into a tiny hole. A portion of the water flow is lifted when the system’s pressure reaches a critical threshold.

These little volumes of water are continually raised and eventually gathered in a storage tank situated above a neighbourhood. Water is subsequently gravity-fed back into the neighbourhood from the storage tank.

In essence, a ram pump consists of two one-way check valves, known as the delivery valve and the waste valve. You only need to briefly open the waste valve to let water flow to get it going. Thereafter, it pumps the water uphill over the source’s elevation on its own.

I believe it’s quite remarkable. To understand how the water operates, let’s take a look at its course. Water first enters the pump and then exits the valve as soon as the waste valve opens. However, the water finally forces the waste valve to slam shut as it accelerates. The pump’s water flow has now halted.

For instance, used automobile tires and door hinges may be used to make new and replacement valves. The system may return unused water to the original water supply if it is properly built. This concept implies that a community may benefit from the free gift of dependable, easily accessible water that is delivered to them waste-free.

The hydraulic ram is a pump that can elevate water without the need for external power. A hydraulic ram’s capacity to function well depends on the availability of a significant amount of water with a small positive head or height.

A little amount of water may be raised to a bigger height using this huge amount of water at a small height. It operates on the “water hammer” concept.

Advantages Hydraulic Ram Pump

- No moving parts.

- No power requirements.

- Affordable.

- Quiet, continuous pumping.

- Pollution-free.

- Simple construction and installation.

- Low initial and maintenance expenses.

Learn about Water Pump with this detailed guide!

Disadvantages Hydraulic Ram Pump

- Can only pump one-tenth of the received volume.

- Requires continuous supply at minimum height of 3 feet or 91 cm.

- Can’t pump viscous fluids to greater heights.

- Typically used for drinking or potable water.

FAQs

What are the disadvantages of a hydraulic ram pump?

The majority of ram pump systems require rivers that flow continuously because they offer a consistent supply of water. Another clear drawback is the inability to recapture and pump the water that exits the waste valve higher without external power input.

What is the use function of hydraulic rams?

One essential part of hydraulic systems is hydraulic rams. These systems transfer electricity from one place to another using pressurised fluid. These systems are perfect for heavy-duty applications because they use hydraulics to create massive forces with comparatively tiny parts.

Can a ram pump generate electricity?

In the end, the procedure lowers the system pressure enough that the waste valve can reopen and the supply valve can close, allowing the process to restart. Numerous water pumps may function as turbines to produce electricity [4]. Ram pumps are not an exception when modified appropriately.

How high can a hydraulic ram pump water?

400 feet

It is feasible to achieve flow rates of 14 gallons (ca. 53 l) per minute or 20,000 gallons (ca. 76 m³) per day with hydraulic ram pumps that are appropriately sized and mounted. Depending on the amount and rate of water flow from the source, water can be raised as high as 400 feet (0.12 km).

Does a ram pump need running water?

A hydraulic ram depends on a non-pressurised water flow via a “drive” pipe that runs from the water source to the pump. The hydraulic ram is positioned some distance below a water source, and the drive pipe is routed from the water source to the pump to provide this flow.